Based on 90 years of experience and many of its own patents, FRAKO has created compensation capacitors using a unique technology, considered to be one of the best solutions of this type on the market. They are used in reactive power compensation systems all over the world. Since 2018, the official representative of FRAKO in Poland is JEAN MUELLER POLSKA Sp. z o. o. based in Warsaw.

FRAKO LKT compensating capacitors have been manufactured exclusively at the company's headquarters in Germany, in Teningen (Baden-Württemberg), for several decades. This allows us to maintain consistently high quality, which is the basis for safe operation and long product life. The offer includes 4 types of capacitors in 1- and 3-pole versions, with a rated voltage of Un = 240-800 [V] AC and a power of up to 40 [kvar], which can be classified according to parameters and thus the area of application. These versions are: Basic, Standard, Premium and Heavy Duty. The latter, in terms of their parameters, significantly exceed the requirements contained in the subject standard EN 60831-1 and -2.

FRAKO LKT compensating capacitors have been manufactured exclusively at the company's headquarters in Germany, in Teningen (Baden-Württemberg), for several decades. This allows us to maintain consistently high quality, which is the basis for safe operation and long product life. The offer includes 4 types of capacitors in 1- and 3-pole versions, with a rated voltage of Un = 240-800 [V] AC and a power of up to 40 [kvar], which can be classified according to parameters and thus the area of application. These versions are: Basic, Standard, Premium and Heavy Duty. The latter, in terms of their parameters, significantly exceed the requirements contained in the subject standard EN 60831-1 and -2.

Check out FRAKO compensation capacitors in Onninen

Production of compensation capacitors

FRAKO capacitors are made using the so-called dry technology. Their windings are enclosed in a cylindrical aluminum housing with an M12 mounting and grounding screw. In addition to the filler, which is non-flammable and free of PCB compounds, a viscous stabilizer is used in the form of mineral oil which, after evaporation, dries to form a solid structure. At the production stage, capacitors undergo multi-point quality control, including: their: capacity, tightness of the housing, insulation, tape rolls, discharge resistance value and voltage resistance. Then they go to a vacuum chamber where they are conditioned at high temperature.

A metalized polypropylene foil divided into segments with self-regenerative properties is used as the dielectric. Each segment is bridged and connected to the electrical circuit. The bridges are designed to disconnect the segment if a puncture occurs. The high temperature of the arc causes evaporation of the metalized layer, spontaneously separating the damaged area. The entire process takes only a few [ms] and has virtually no impact on the parameters of the capacitor, which remains operational during and after breakdown.

A metalized polypropylene foil divided into segments with self-regenerative properties is used as the dielectric. Each segment is bridged and connected to the electrical circuit. The bridges are designed to disconnect the segment if a puncture occurs. The high temperature of the arc causes evaporation of the metalized layer, spontaneously separating the damaged area. The entire process takes only a few [ms] and has virtually no impact on the parameters of the capacitor, which remains operational during and after breakdown.

FRAKO compensation capacitors

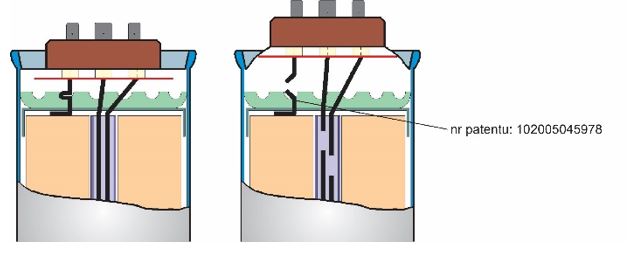

Construction of a compensation capacitor

Inside the casing of the reactive power capacitor there is the so-called overpressure fuse, patented by FRAKO in 2005. It is a special copper wire (or wires for the 3-phase version) with constrictions, designed to safely disconnect the capacitor from the network when the critical pressure is exceeded. inside the housing. It is additionally insulated, thus protecting the internal elements of the capacitor against electric arc. In practice, when the pressure limit is exceeded, the upper cover of the capacitor, made as a membrane, bends upwards and the wires attached to it break in weakened places. Thus, the capacitor is safely disconnected from the network without causing any danger.

Capacitors are very sensitive to elevated temperatures. Excessive temperature increase may be caused by many factors: installation location, operating and ambient conditions, presence of higher harmonics, etc. Please remember that the dielectric constant of polypropylene film is inversely proportional to temperature. The higher it is (T), the dielectric constant decreases and the foil loses its dielectric properties. All FRAKO capacitors meet the highest temperature class D (according to EN 60831) and the Premium and Heavy Duty versions are adapted to work at elevated temperatures - max. 65°C and 68°C.

Capacitor connection terminals

It is also worth paying attention to the capacitor connection terminals made using Cage-Clamp technology. Strong anti-vibration springs ensure constant, lasting pressure, and the clamp housing itself has an IP20 protection rating. The clamps are maintenance-free and do not require maintenance or frequent inspection. There are discharge resistors under the terminals, which are designed to discharge the capacitor to a safe voltage of 50V in < 60 s. Capacitors often operate in networks with a high content of harmonics, the presence of which results in a reduction of the capacitor's reactance and thus an increase in the current flowing through the capacitor itself. For this reason, all FRAKO LKT versions withstand permanent overload with a current of at least 1.5xIn, and in the case of Premium or Heavy Duty versions it is 2.2xIn and 2.7xIn, respectively.

It is also worth paying attention to the capacitor connection terminals made using Cage-Clamp technology. Strong anti-vibration springs ensure constant, lasting pressure, and the clamp housing itself has an IP20 protection rating. The clamps are maintenance-free and do not require maintenance or frequent inspection. There are discharge resistors under the terminals, which are designed to discharge the capacitor to a safe voltage of 50V in < 60 s. Capacitors often operate in networks with a high content of harmonics, the presence of which results in a reduction of the capacitor's reactance and thus an increase in the current flowing through the capacitor itself. For this reason, all FRAKO LKT versions withstand permanent overload with a current of at least 1.5xIn, and in the case of Premium or Heavy Duty versions it is 2.2xIn and 2.7xIn, respectively.

Check out FRAKO compensation capacitors in Onninen

Frako products available at the Onninen installation wholesaler

In addition to capacitors for reactive power compensation, FRAKO offers a whole range of other devices such as: filtering and discharge chokes, switching contactors, reactive power regulators, active and passive filters, ready-made compensation modules, and devices for managing electricity in LV switchboards. More information about the products, including a catalog and a Q power compensation manual for designers and users, can be found at www.jeanmueller.pl

Remigiusz Chmielewski

JEAN MUELLER POLAND