When creating electrical installations, as well as their modernization, it is necessary to determine how the connection of aluminum wires will be made within the entire installation. Before starting any work, it is also worth determining why aluminum wires are better than copper. Until now, old electrical installations were built exclusively from copper wires. Such infrastructure has generated a lot of problems to this day, e.g. electrolytic corrosion occurs. So how do you connect aluminum wires and what to do when you want to connect them to copper wires? Learn effective and safe work methods.

Check out the aluminum cables at the Onninen wholesaler

What is the correct technique for joining aluminum cables?

Modern power cables are mainly available in copper versions. This is primarily due to the excellent electrical conductivity of this material, as well as the high level of safety of using copper wire connections. In this case, connecting wires is simple and does not generate the risk of, for example, damaging the wires in the installation - good connectors or electrical blocks are enough.

Modern power cables are mainly available in copper versions. This is primarily due to the excellent electrical conductivity of this material, as well as the high level of safety of using copper wire connections. In this case, connecting wires is simple and does not generate the risk of, for example, damaging the wires in the installation - good connectors or electrical blocks are enough.

To properly connect aluminum cables and wires , you need to use special connectors designed for this material . Such terminals are corrosion-resistant and have a special coating that prevents oxidation of the aluminum inside the connectors, e.g. WAGO.

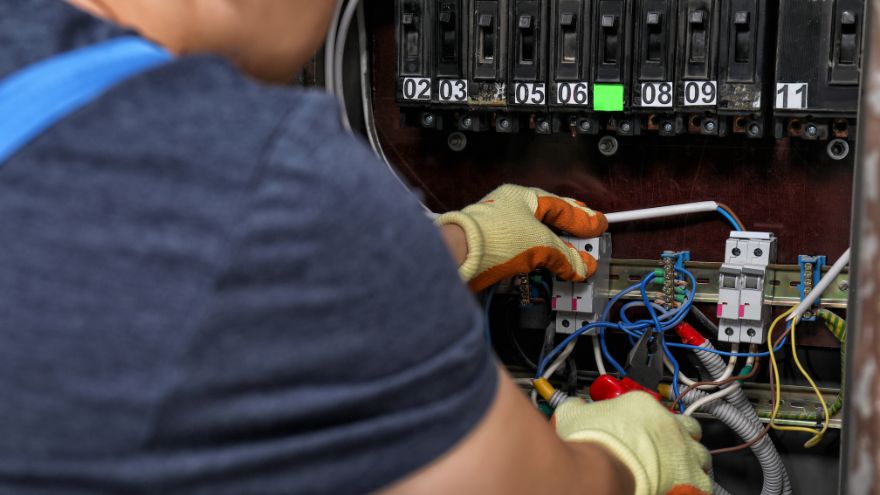

If you want to safely connect aluminum wires, use the following tips:

- Thoroughly clean all wires before making the connection. Once the aluminum oxide is removed, you can coat the wires with a conductive paste, which will reduce the risk of the material oxidizing again.

- Only use dedicated connectors that can safely connect aluminum PVC cables .

- Use specialized conductive pastes, so-called corrosion inhibitors. This is a type of grease that prevents oxidation of aluminum wires.

- Make sure to use the proper amount of force when screwing the wires. Stability is key when using aluminum cables. A loose wire can heat up, and a loose screw can also damage the wire.

Also, try to use materials and connectors that comply with the PN-IEC 60364 standard during work. You will gain certainty that the electrical installation built from aluminum wires will be properly protected against failures.

Can WAGO connectors be used to connect installation cables?

In the case of copper wires, and also when it comes to connecting aluminum wires in electrical installations, you can definitely use WAGO connectors. Such installation accessories facilitate assembly, improve the safety of the installation, and are also reliable.

In the case of copper wires, and also when it comes to connecting aluminum wires in electrical installations, you can definitely use WAGO connectors. Such installation accessories facilitate assembly, improve the safety of the installation, and are also reliable.

The types of WAGO installation connectors that are suitable for connecting installation cables using a clamp are mainly the following versions:

- spring series 221, which are suitable for home installations, distribution boxes and switches,

- small connectors series 2273 – ideal for connecting single-core copper and aluminum wires.

By using WAGO electrical connectors, electrical connections in homes and companies will be safe and reliable. The installations also use Alu-Plus paste from WAGI, which increases the electrical conductivity of cables.

Connecting Aluminum and Copper Cables – What You Should Know

Aluminum and copper wires can be freely connected, but only using specific methods and taking into account safety regulations. Aluminum and copper wires can be compared to competitors in the ring. The former are light and cheap, but the latter conduct electricity better and are safer.

An incorrect connection can cause the copper to destroy the aluminum and increase the contact resistance, which can cause a fire in the electrical installation.

An incorrect connection can cause the copper to destroy the aluminum and increase the contact resistance, which can cause a fire in the electrical installation.

Therefore, to connect aluminium and copper wires, connections can be used in installation boxes using special sleeves in which contact paste is placed.