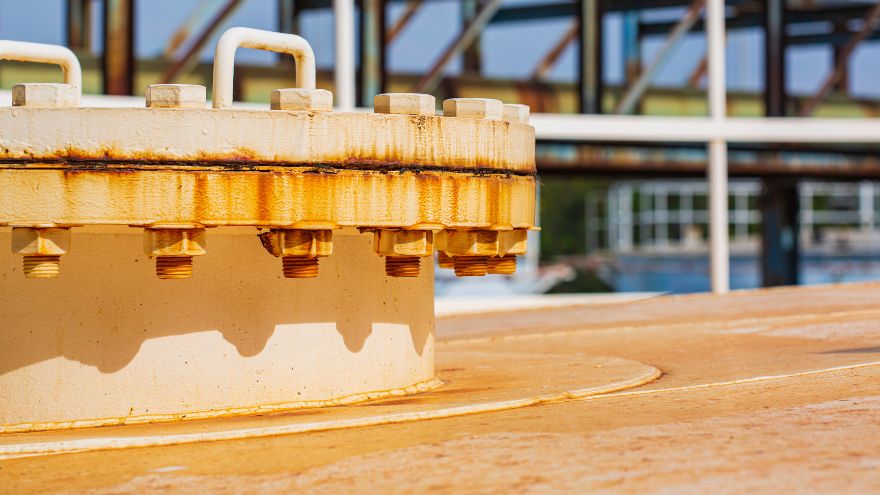

During their life, everyone has certainly encountered a reddish coating on metal surfaces. This is corrosion, also known as rust, the greatest enemy of many metals and their alloys, including the very popular steel. This phenomenon is highly undesirable and also affects other materials. We are talking about concrete, wood, rocks, plastics, and glass. It is estimated that corrosion leads to the destruction of up to 25 million tons of steel annually, and the annual losses per capita due to this are estimated to be over $1,000. Learn about the corrosivity classes, what they mean, and how to protect metals from corrosion.

Check out corrosion inhibitors at the Onninen wholesaler

What are corrosivity classes?

Corrosion classes are established standards that provide information on how quickly metals will degrade in specific environments. Standards will help us learn how to select protection for metal surfaces to make them resistant to corrosion.

Corrosion classes are established standards that provide information on how quickly metals will degrade in specific environments. Standards will help us learn how to select protection for metal surfaces to make them resistant to corrosion.

The corrosivity categories have been established, among others, by the ISO 12944 standard. The exact parameters of the individual environments may differ between countries due to the climate in which they are located and other factors. Corrosivity classes are of great importance, for example, in industry, because they make it easier to select protection for steel elements that make up production plants.

Of course, not all metals are susceptible to corrosion. When using copper or aluminum, you can apply a thinner coating, or completely eliminate it, depending on the environment and its corrosivity class.

Classification of atmospheric corrosive environments

The ISO 12944 standard distinguishes precisely six classes of corrosive environments. They indicate how aggressive and dangerous a given place is for metals. Each class also provides examples of places to which they apply both inside and outside buildings.

Class C1

Class C1 is the basic category of corrosivity. It occurs in indoor environments with a clean atmosphere. These are heated and ventilated buildings such as schools, offices, hotels, shops or public institutions. In such an environment, metals susceptible to corrosion can be used, because the risk of its occurrence is extremely low.

Class C2

Class C2 means an environment with a low risk of corrosion (corrosion-resistant class). In the case of internal conditions, it applies to unheated buildings, but not containing an excess of risk factors. These can be halls, warehouses or sports facilities. The external environment corresponding to this class is in turn rural areas, where there are very few pollutants in the atmosphere.

Class C2 means an environment with a low risk of corrosion (corrosion-resistant class). In the case of internal conditions, it applies to unheated buildings, but not containing an excess of risk factors. These can be halls, warehouses or sports facilities. The external environment corresponding to this class is in turn rural areas, where there are very few pollutants in the atmosphere.

Class C3

Class C3 corresponds to environments with high humidity. This is an average category, where the strongest protection against corrosion is not yet necessary. However, using ordinary low-carbon steel there can result in rapid destruction of the metal. This class occurs in industrial and urban areas characterized by medium sulfur oxide pollution. Examples of indoor environments include food plants and are characterized by high humidity.

Class C4

High corrosivity class. Hazardous environment for metals that require strong protection. Used for places such as chemical plants, shipyards, swimming pools, or heavily industrialized areas. Coastal areas with medium salinity are also included in this class.

Class C5-I

The highest, industrial class of corrosivity. In such an environment, very effective protection against corrosion and factors that threaten metal should be used. Examples of such places are industrial areas, where there is very high air humidity and its pollution.

Class C5-M

An alternative to the industrial C5 standard. This is a marine environment, where steel is most exposed to moisture. If the metal is to be exposed to such conditions, it is essential to use the most effective anti-corrosion coatings. This environment corresponds to coastal areas and seas with high salinity. The recommendations of this corrosivity class are used, for example, in the production of ships and vessels.

What determines the corrosivity category?

The corrosivity class is determined based on various factors. The aggressiveness of the environment is determined by the level of humidity or the presence of chemical compounds in the atmosphere. The more water, as well as harmful compounds such as sulfur oxides, the higher the corrosivity class. Thanks to this, you can find out what properties metals used in such places should have.

Anti-corrosion paint at the Onninen wholesaler

Do you need to protect metal from corrosion? Choose a special paint that will create an effective coating that protects steel or cast iron surfaces from moisture. At the Onninen wholesaler you will find various products, such as corrosion inhibitors or anti-corrosion paints . To protect home central heating installations, you can choose the De Dietrich MC1+ CH1-03-01723-WE corrosion inhibitor . Kopos Weicon 750 XX WEICON 750_XX zinc anti-corrosion paint can be used to renew the coating on previously protected steel. Are you looking for a product that will fully protect your central heating installation? Choose the FERNOX Alphi-11 5 L corrosion inhibitor .

Do you need to protect metal from corrosion? Choose a special paint that will create an effective coating that protects steel or cast iron surfaces from moisture. At the Onninen wholesaler you will find various products, such as corrosion inhibitors or anti-corrosion paints . To protect home central heating installations, you can choose the De Dietrich MC1+ CH1-03-01723-WE corrosion inhibitor . Kopos Weicon 750 XX WEICON 750_XX zinc anti-corrosion paint can be used to renew the coating on previously protected steel. Are you looking for a product that will fully protect your central heating installation? Choose the FERNOX Alphi-11 5 L corrosion inhibitor .