Laying and connecting optical fibers requires not only specialist knowledge from the installer, but also great care and caution. The attenuation of the transmitted signals will depend on the precision of the work performed. The process of connecting optical fibers ends with appropriate protection of the places where the optical fibers are welded. For this purpose, fiber optic joints are used. The joint protects the optical fiber and the splice against mechanical damage and negative weather conditions.

Check out fiber optic joints at the Onninen wholesaler

Methods of connecting optical fibers

Methods of connecting optical fibers can be divided into:

-

solid – prepared fibers are connected using permanent joints or splices;

solid – prepared fibers are connected using permanent joints or splices; - detachable - using various types of connectors and sockets (the cleaned fiber is brought one end to the other and positioned appropriately).

The detachable method is simple and allows for easy changes to the infrastructure. However, welding is considered the most qualitative method of connecting optical fibers, guaranteeing very good installation parameters - of course, provided that the splice is properly performed and properly secured. There are two main solutions to choose from.

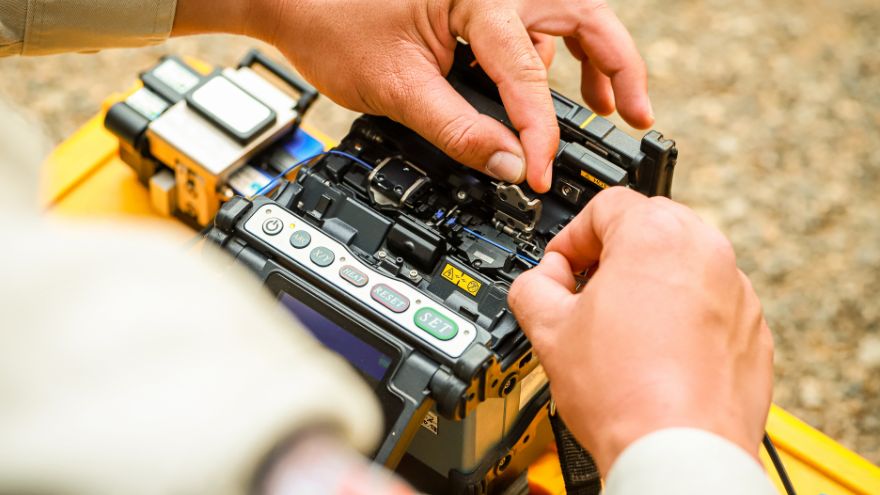

- Thermal welding – this method requires the use of a welding machine that produces an electric arc. The connection occurs as a result of melting of the optical fiber ends. The advantage of this method is obtaining a strong, durable and reliable connection.

- Mechanical splices – they are placed in fiber optic boxes or joints . Housings are used to position the fibers and remove unevenness. Before making the connection, the installer uses a visual damage locator and checks whether the cut fibers match the parameters of the welding machine/mechanical splice. Failure to adjust the length of the sections to the selected method may result in such strong attenuation that signal transmission will be impossible.

It is worth remembering that the process of connecting optical fibers must be preceded by their proper arrangement and preparation. Cleaning and cutting cables is undoubtedly a difficult task, especially for novice installers. You need to remove the cable sheath until the desired diameter is reached, clean the fiber thoroughly using dust-free wipes, and then cut it using a special cutter. By following this order, you avoid the risk of dirtying the cut fiber. Thorough cleaning has a significant impact on the subsequent welding process.

It is worth remembering that the process of connecting optical fibers must be preceded by their proper arrangement and preparation. Cleaning and cutting cables is undoubtedly a difficult task, especially for novice installers. You need to remove the cable sheath until the desired diameter is reached, clean the fiber thoroughly using dust-free wipes, and then cut it using a special cutter. By following this order, you avoid the risk of dirtying the cut fiber. Thorough cleaning has a significant impact on the subsequent welding process.

After completing the work, measure the attenuation of the transmission path using a meter and a constant power light source. The result provides information on the correct operation and implementation of the fiber optic installation. It is important to remember that damage to optical fibers is more difficult to detect than to coaxial cables. In the case of small installations, it is known whether it is necessary to use an optical attenuator in the transmission window to reduce the power at the receivers.

How to connect optical fibers using fiber optic joints?

A fiber optic joint is a very important element of optical infrastructure. It is used to effectively protect the place where optical fibers are welded, helps to properly position the fibers and connect them effectively, has a protective function and provides installers with free access to the connections in order to easily and safely carry out repairs (it is not necessary to remove the cables along the entire section). The use of joints allows for continuity of transmission, which translates into optimally functioning optical fiber. Fiber optic joints can be mounted in a cable well, on walls or poles - depending on the type of network. Fiber optic connections should always be performed by a professional installer.

A fiber optic joint is a very important element of optical infrastructure. It is used to effectively protect the place where optical fibers are welded, helps to properly position the fibers and connect them effectively, has a protective function and provides installers with free access to the connections in order to easily and safely carry out repairs (it is not necessary to remove the cables along the entire section). The use of joints allows for continuity of transmission, which translates into optimally functioning optical fiber. Fiber optic joints can be mounted in a cable well, on walls or poles - depending on the type of network. Fiber optic connections should always be performed by a professional installer.

Fiber optic joints in the Onninen wholesaler

In the Onninen installation wholesaler you will find fiber optic joints differing in capacity (maximum number of splices), installation method and purpose. We offer products of proven quality, whose housings are highly resistant to weather conditions, dust and pollution.