Pipelines are an important part of any building. Without proper protection, they are subject to damage, which can be very expensive to repair. The way to avoid such situations is to install DEVI heating systems to protect pipelines.

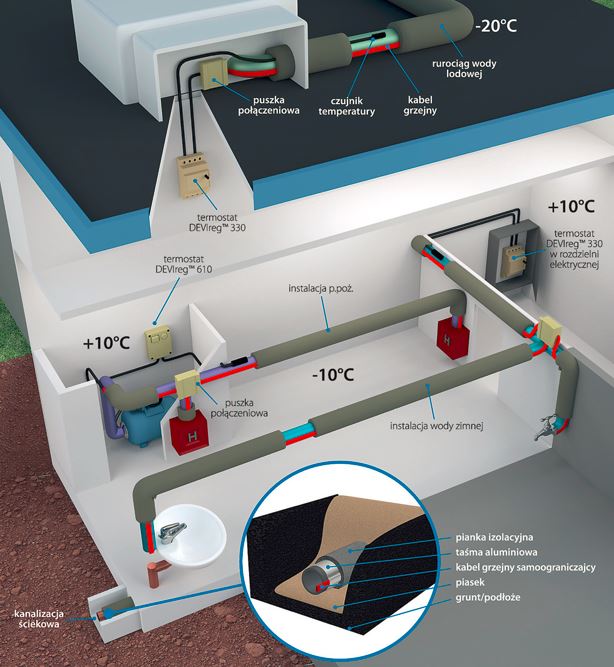

DEVI pipeline protection systems can be installed on pipes in internal and external installations of buildings of any purpose, as well as on above-ground and underground pipelines. They include heating cables, thermostats and mounting accessories. Thanks to DEVIreg™ thermostats, it is possible to ensure optimal working conditions and achieve a specific effect with the least amount of energy consumed.

In addition to the main goal of eliminating frost damage, there are many additional benefits that DEVI systems provide. These are:

- ice free pipes,

- constant flow in pipes,

- reducing the depth of pipe installation underground,

- no repair costs after a harsh winter,

- free transport of fatty products,

- efficient hot water supply.

DEVI thermostats and heating cables in the wholesale offer

Selection of the heating system

The DEVI system selection procedure includes the following steps: calculation of heat losses, selection of a heating cable, determination of the length of the circuits, selection of control and installation accessories.

Selection of the power of heating cables involves determining heat losses resulting from the need to maintain a constant positive temperature inside the pipe and the assumed lowest ambient temperature. Losses can be determined by calculation or use ready-made tables.

Selection of heating cables

Constant power type heating cables can be used to heat pipes DEVIflex ™ or self-limiting cables DEVIpipeguard ™ and DEVIiceguard ™ . In practice, self-limiting cables with unit powers of 10 W/m, 18 W/m, 25 W/m and 33 W/m at a temperature of 10 o C or cables with a constant unit power of 10 W/m and 18 W/m are most often used.

Specifying the unit power for self-limiting cables at a specific temperature is necessary because the amount of power dissipated on them varies inversely with changes in the ambient temperature.

This means that these cables automatically adjust the amount of power dissipated on them to the ambient temperature. Constant power cables dissipate a constant amount of power, regardless of changes in ambient temperature.

When designing a pipe heating installation with a self-limiting heating cable, it is necessary to take into account the fact that the power on the heating cable increases as the ambient temperature decreases. This determines the selection of its maximum length, and therefore also the power dissipated along the entire length of the cable, resulting from the selected fuse in the electrical power supply circuit.

Selection of controls for heating cables

Both constant power and self-limiting cables require the use of a control thermostat, thanks to which the heating cable will maintain the appropriate temperature inside the pipe. Additionally, in the case of pipe protection, the thermostat acts as a switch for the entire heating system outside the winter period. This also applies to self-limiting cables, which consume electricity even at relatively high ambient temperatures. The type of temperature control used and the method of its expansion depend on the specific installation. The two most frequently used methods are control by measuring the temperature of the air surrounding the pipeline (air temperature sensor) and control by measuring the temperature directly on the pipeline (contact sensor). The most commonly used thermostats are DEVIreg™ 330, DEVIreg™ 316 or EKC-302A intended for installation in an electrical switchboard on a TH rail. You can also use a thermostat DEVIreg™ 610 for surface mounting. The required temperature is set on the thermostat.

Pipeline heating system - practical information

The pipeline heating system using heating cables requires the following basic conditions:

- the entire length of the cable should be attached to the pipe surface with self-adhesive aluminum tape,

- in the case of plastic pipes (PVC, PP, PE), before laying the cable on the pipe, at the place of installation, stick a self-adhesive aluminum tape to the pipe surface to protect the pipe surface against overheating,

- heating cable screens must be connected to the protective conductor of the electrical installation,

- heating cables cannot be laid at an ambient temperature below -5oC,

- constant power heating cables cannot touch or cross each other,

- the heating system must be connected to the electrical installation by an electrician with appropriate SEP qualifications.

See the products of Devi cable heating systems at the Onninen wholesaler