Gas fuel heating installations use not only carbon steel pipes, but also copper pipes. The use of the latter is supported by the excellent physical and mechanical properties of this metal. The safe operation of copper gas installations is guaranteed by compliance with specific standards and regulations. Get to know the most important of them!

From this article you will learn:

- what are the requirements for copper pipes in gas installations,

- what methods of connecting copper pipes are used in the gas installation,

- what are the advantages and disadvantages of a copper gas installation.

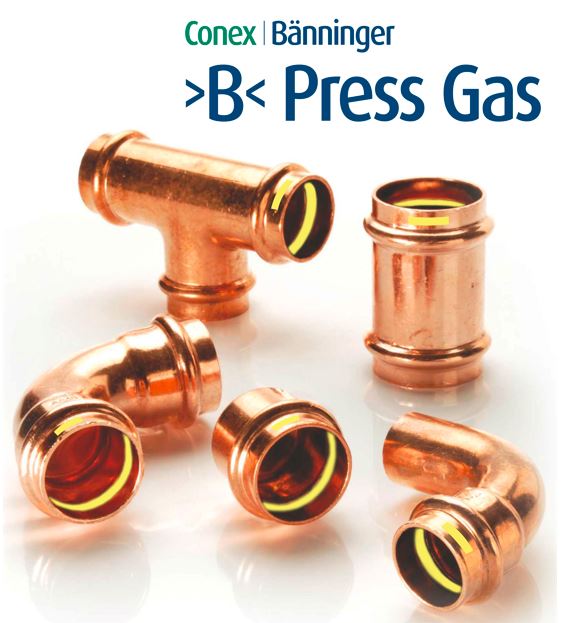

Check out gas installation connectors from Conex Banninger

Requirements for copper pipes in gas installations

The requirements for the use of copper pipes in gas installations are included in the PN-En 1057 standard. They must be very durable and easy to install. They are produced in three different states - hard, semi-hard and soft. It is worth remembering that they cannot be covered or run in closed channels.

Pipes intended for gas installations are made of copper deoxidized with phosphorus. The thickness of their walls depends on the external diameter, which ranges from 10 to even 267 mm. One of the key parameters of pipes is also the cleanliness of their surface in terms of mechanical waste and the presence of carbon.

| Outer diameter [mm] | Wall thickness [mm] |

| 10; 12; 15; 18 | 1 |

| 22; 28 | 1.2; 1.5 |

| 35; 42 | 1.5 |

| 54 | 2 |

| 64 | 2 |

| 76.1 | 2 |

| 88.9 | 2 |

| 108 | 2.5 |

| 133; 159; 219; 267 | 3 |

It should also be remembered that in order to put the gas installation into operation, it must be subjected to a correctness inspection procedure. The installer is therefore obliged to carry out a pressure test to verify the tightness of the gas system. The protocol must be signed by both the installation contractor and the building owner. It is worth noting that a representative of the gas supplier does not have to participate in this process.

However, the conditions for gas connection must be agreed with the operator and a contract for its supply must be signed. For this purpose, it will be necessary to complete the application "Registration of the building for filling the gas installation with gas fuel". It must include:

- applicant's personal data,

- information regarding the location of the building,

- declaration of the construction manager on the implementation of the installation in accordance with the design,

- declaration of a positive pressure test,

- declaration of having a current chimney sweeper's opinion.

Methods of connecting copper pipes in a gas installation

Polish regulations allow two ways of connecting gas pipes made of copper:

- using hard-soldered connectors,

- using pressed connectors.

The first of these methods was first mentioned in the Regulation of the Minister of Infrastructure on the conditions to be met by buildings and their location of April 12, 2002. The second one is in line with the general requirements regarding the tightness of the gas installation and its safety, specified in Polish standards. To connect copper pipes you can use:

- copper connectors and bronze connectors for capillary soldering,

- pressed copper and bronze connectors,

- threaded connectors made of bronze.

While the first two types of products are used to connect copper pipes, threaded connectors can be used to connect copper and steel pipes. It is also worth remembering that flux will be necessary when soldering copper elements with bronze connectors.

Running copper pipes in the gas installation

A copper gas installation is subject to more stringent restrictions than a system made of black steel pipes connected by welding. First of all, remember that copper pipes cannot be placed outside the building. They are only suitable for internal use. As we mentioned earlier, they must not be run through closed channels or covered in any way (e.g. plastered).

A copper gas installation is subject to more stringent restrictions than a system made of black steel pipes connected by welding. First of all, remember that copper pipes cannot be placed outside the building. They are only suitable for internal use. As we mentioned earlier, they must not be run through closed channels or covered in any way (e.g. plastered).

The reason for the ban on the use of copper pipes on the external wall of the building is the difference between the temperature of the transmitted gas and the air temperature, which may cause water vapor to condense on their surface. In the case of steel pipes, this problem does not occur.

Some installers have doubts about running copper pipes in the stairwell of a multi-family building. It is worth noting that the wall separating individual apartments from the public corridor is not an external wall of the building. Laying copper pipes behind a gas meter or behind a branch to a separate apartment is therefore interpreted as permitted.

Exchange benefits in the new OnnTop loyalty platform!

Advantages and disadvantages of copper gas installations

It is not without reason that copper pipes are widely used in both residential and industrial construction. Due to their favorable physical properties, they are used in many different installations. Which of their advantages are most important from the point of view of gas heating systems?

- Resistance to destructive factors - copper pipes are resistant to various harmful factors, especially high temperatures. Thanks to this, they can be used in extreme conditions, without the risk of deformation or release of hazardous substances. All this translates into an extended service life of copper pipes.

- Ease of installation - the strength of copper pipes makes their walls noticeably thinner than other materials. Thanks to this, they take up less space and are easier to install. An additional convenience is the availability of various ways of connecting copper pipes.

- Aesthetics - previously mentioned that copper gas pipes must not be covered, so they remain visible after installation. Fortunately, they have a very attractive appearance.

- Ecology - it is also worth remembering that copper is fully recyclable and has no harmful impact on the environment.

However, it should be noted that copper gas pipes also have their disadvantages. One of them is undoubtedly the already mentioned limitation regarding the place of their use. Moreover, the process of connecting copper pipes with other metals, which corrode faster when in contact with them, requires special attention. Therefore, any contact point should be isolated, for example with a brown spacer.

When talking about the disadvantages of copper pipes, it is impossible to ignore the issue of their price. In this case, the cost of installing a gas installation may be up to 40% higher than using steel.

You must complete your gas installation project with Onninen!

Installing a gas installation requires the use of high-quality pipes and elements for connecting them. So choose copper pipes and connectors, which you will find in our online wholesaler. The Onninen range includes products of various diameters, so you can easily adapt them to the specificity of each gas installation you are working on!