In technical devices, installers, distributors and users have always valued solutions that are known, proven and reliable. They also expect advanced technologies from modern devices that facilitate installation, start-up, operation and servicing and guarantee compliance with restrictive requirements regarding energy efficiency and rational use of energy. In relation to circulation pumps for home installations, Grundfos ALPHA1 L pumps offer just such a combination of features.

Check out Grundfos Alpha1 pumps at the Onninen wholesaler

ALPHA1 L – types of regulation

The ALPHA1 L pumps have taken over the manual gear change from their reliable predecessors, the UPS Series 100 pumps, i.e. the selection of one of three fixed rotational speeds. On the control panel of these pumps, the selected gear is signaled by a simple combination of diodes.

Photo 1. Setting the control types on the ALPHA1 L pump control panel

The number of diodes lit in one series determines the pump speed, i.e. the selection of one of three constant characteristics. Due to the widespread use of thermostatic valves in new radiator installations and the increasingly popular use of underfloor heating, the types of regulation have been extended to include proportional regulation and maintaining constant pressure throughout the pump capacity range. The first, additional type of regulation is preferred in radiator installations, and the second, in underfloor heating installations. On the control panel, each of these two types of regulation is signalled by a yellow diode next to the given icon.

Photo 2. Signaling the selection of the type of regulation preferred for the radiator installation and underfloor heating installation

ALPHA1 L – high efficiency translates into energy savings

After the EuP directive on energy efficiency of circulation pumps was introduced, traditional pumps equipped with an asynchronous motor were not able to meet its requirements. For this reason, an electronically commutated motor (EMC) with neodymium permanent magnets in the rotor was used in Grundfos ALPHA1 L pumps. Thanks to this, the energy efficiency index EEI for all sizes of these pumps is below 0.20. The lower the EEI, the higher the energy efficiency. The requirements of the directive for circulation pumps specify this index at 0.23, so ALPHA1 L meets this condition with more than enough. The EEI value is determined for a strictly defined control characteristic. It is activated by pressing and holding the control type selection button on the pump control panel for 3 seconds (Photo 1). During normal pump operation, selecting this characteristic is not justified.

Check out Grundfos Alpha1 pumps at the Onninen wholesaler

ALPHA1 L – a versatile pump

Grundfos circulation pumps operate not only as stand-alone devices, but in many installations they cooperate with boiler or heat pump controllers. In order to extend the range of applications of ALPHA1 L pumps, they can be controlled by a low-voltage digital PWM signal. Controlling the PWM signal consists in changing the pump speed depending on the signal's fill factor. For the PWM input signal with profile A, used for heating systems, the pump speed decreases when the digital signal fill factor increases. The pump will reach maximum speed when the fill factor is lower than 10%, and minimum when the factor exceeds 84%. Communication is bidirectional. Information about current power consumption, pump stop due to blocked rotor and due to electronics failure is transmitted from the pump to the controller.

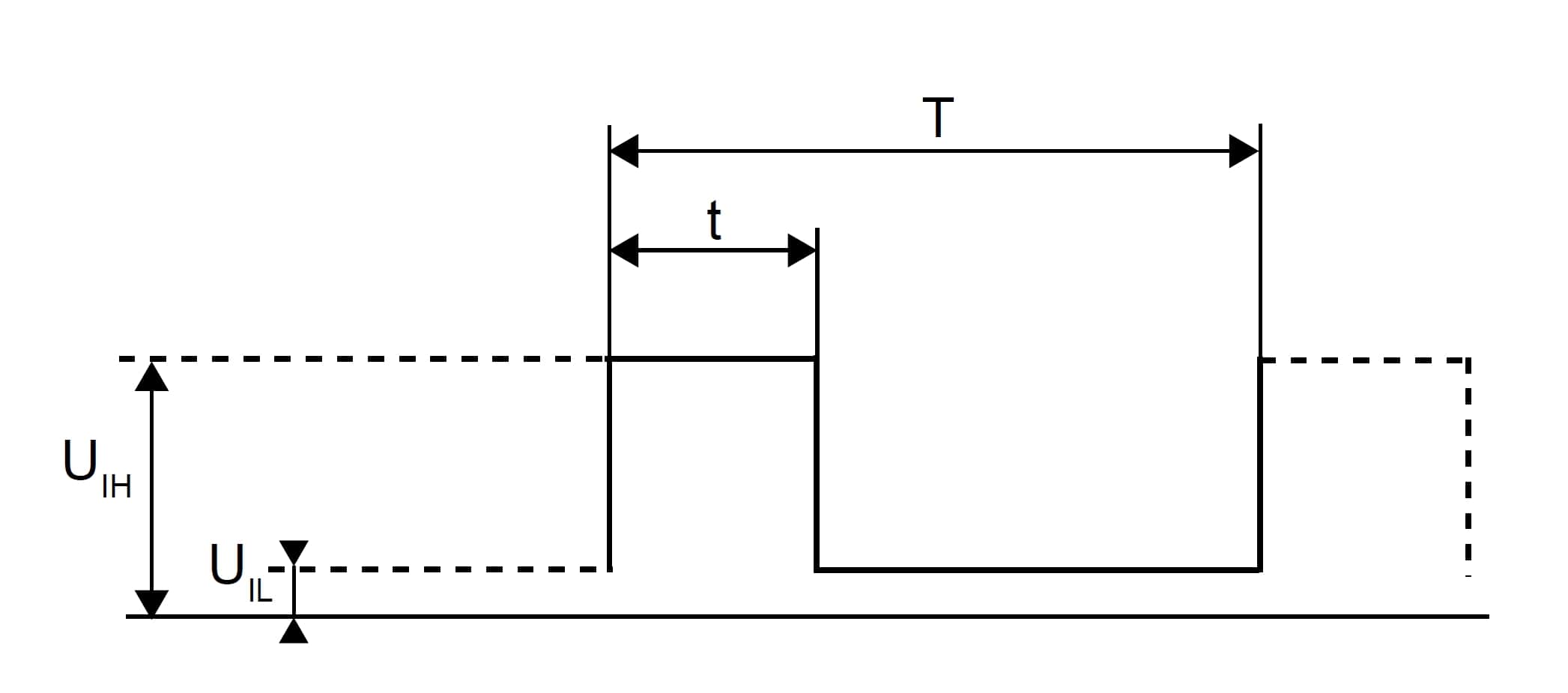

Photo 3. Example of a modulated digital control signal: t – high signal level time, T – control signal period, UIH – high voltage level, UIL – low voltage level

Fill factor:

d = 100 x t/T [%]

If the pump is controlled by a PWM signal, the green LED on the control panel flashes (Fig. 1). If the control cable is disconnected or the signal is zero, the pump switches to the previously selected control type.

Thanks to its compact design, PWM control option and operation at higher ambient temperatures, the ALPHA1 L is suitable for most heating installations. This means you can easily replace a damaged or energy-inefficient pump, saving time and money.

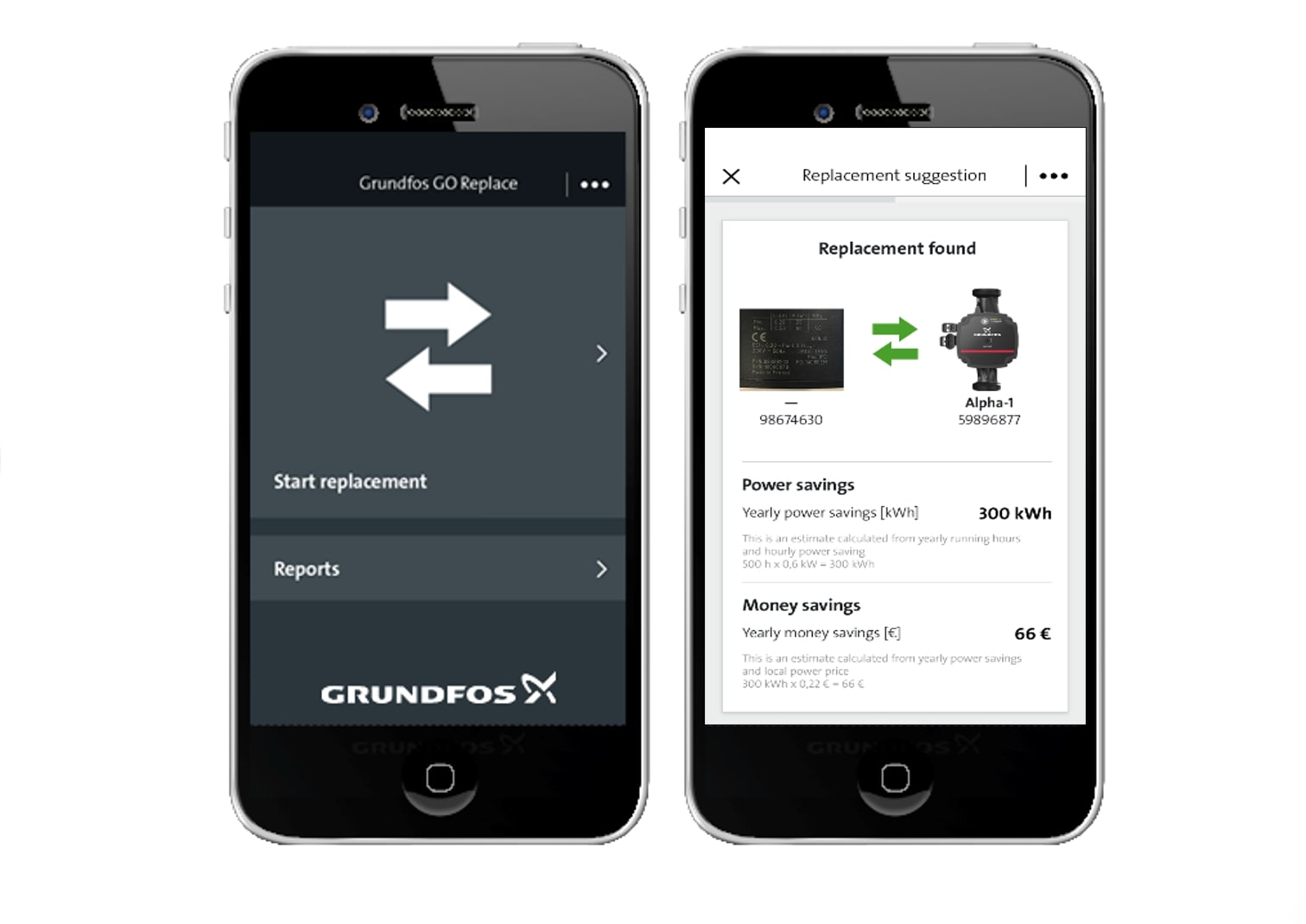

Grundfos GO – an application that makes it easy to replace old pumps with ALPHA1 L

The high energy efficiency of the ALPHA1 L pump and the ability to control it with a PWM signal make the pump a good choice as a replacement for old, much less efficient pumps, both those installed separately in the installation and those installed in boilers and controlled from their controllers. The Grundfos GO application on mobile devices allows you to find not only the right size of the ALPHA1 L pump as a replacement for old or damaged pumps, but also indicates the optimal settings. The report generated in the application also includes information on the method of pump installation (in many cases it is enough to replace only the head of the old pump, without dismantling the housing) and the estimated electricity savings resulting from replacing the old pump with the ALPHA1 L.

Photo 4. GO Replace tool in Grundfos GO app for finding replacement circulation pumps

Check out Grundfos Alpha1 pumps at the Onninen wholesaler

ALPHA1 L – Diagnosing Emergency Conditions

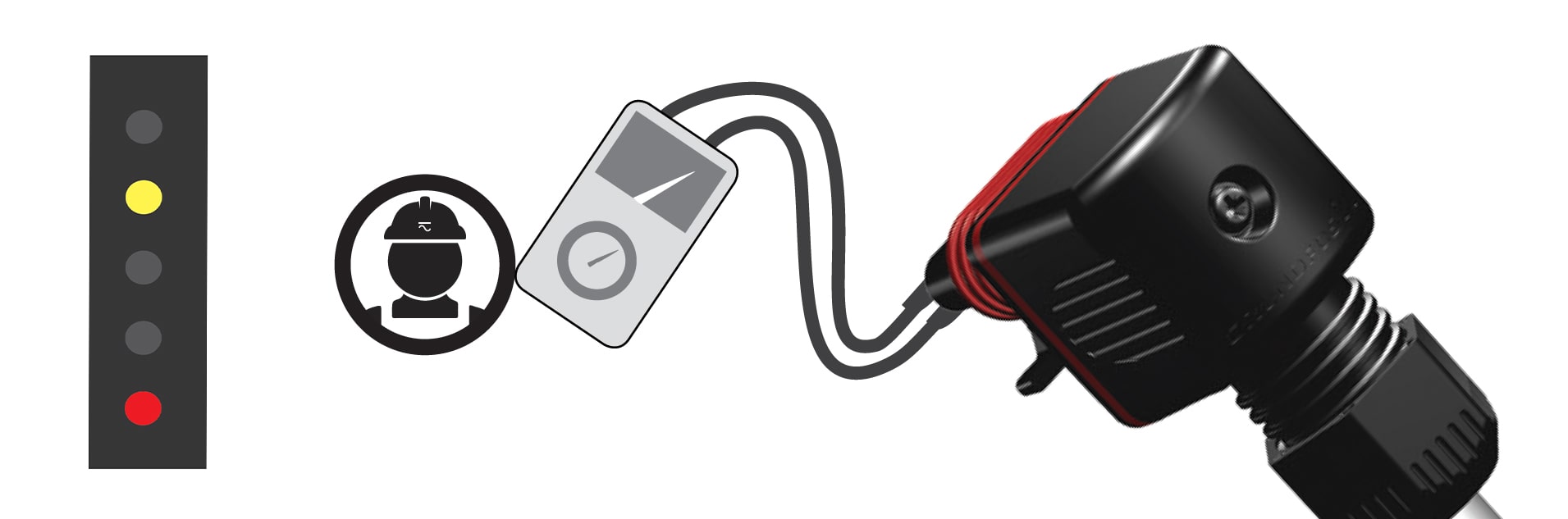

In modern devices, great importance is attached to communicating faults in a clear manner. If the ALPHA1 L pump detects at least one fault, the lowest diode on the control panel changes colour from green to red. The type of fault is defined by the yellow diode accompanying the red diode. If the yellow diode lights up at the furthest position relative to the red one, it means that the pump shaft is blocked, but this fault can be easily repaired. The pump is powered from a single-phase network with an effective voltage of 230 V. If the supply voltage drops but does not fall below 160 V, the pump will operate with reduced efficiency. However, if the supply voltage drops below 150 V, the pump will stop and the yellow diode will light up in a position one position closer to the red diode

Photo 5. Signaling of pump stop due to too low supply voltage

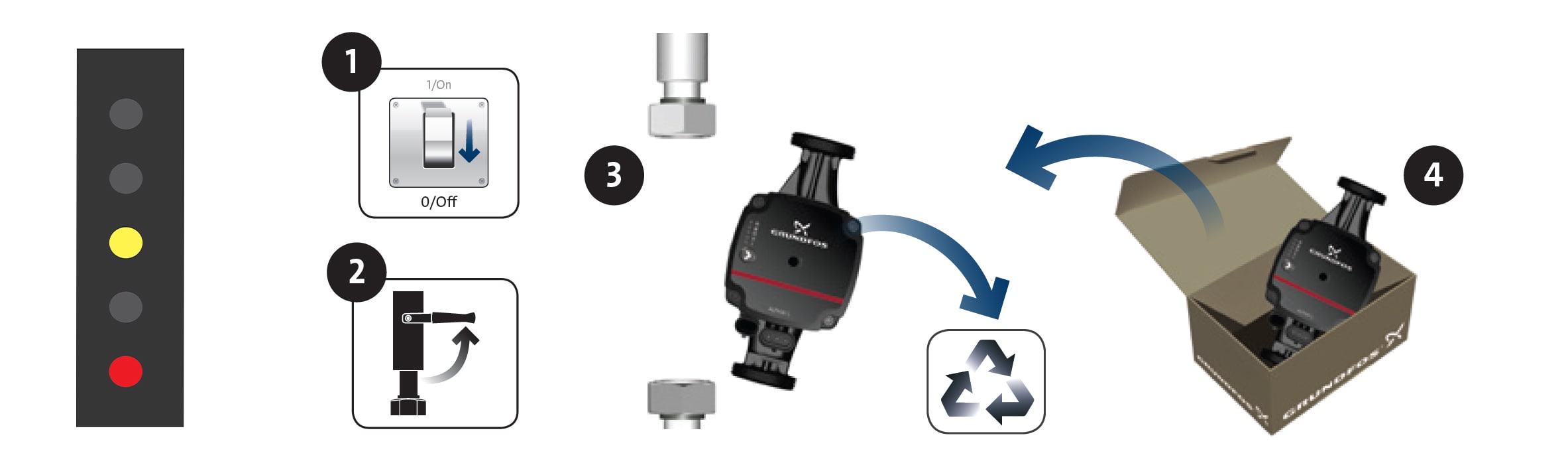

This type of failure is easy to detect and after increasing the voltage the pump will return to normal operation. If the pump stops and the yellow diode closest to the red diode lights up, it will mean a failure of the pump's electrical modules. This is the only case of failure that qualifies the pump for replacement.

Photo 6. Procedure in the event of a failure of the pump electronic modules. 1 - disconnect the power supply, 2 - close the shut-off valves, 3 - replace the pump, 4 - send the damaged pump to an authorized Grundfos service center

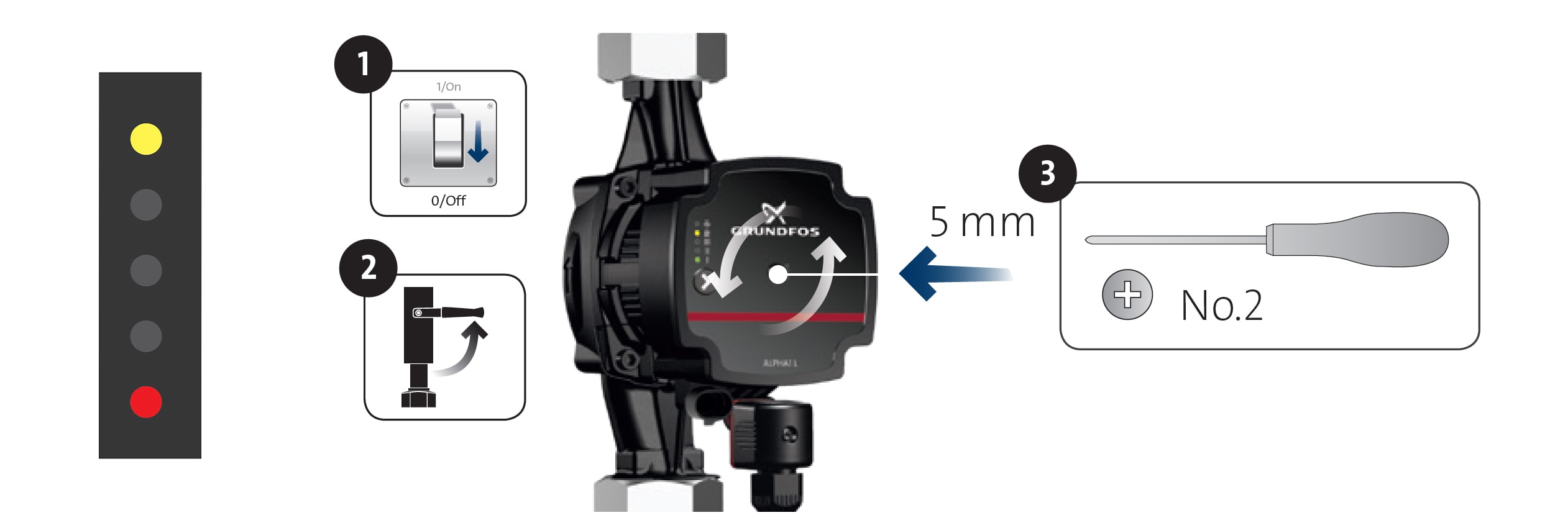

The deposition of calcium compounds or other impurities in water can result in the blocking of the shaft on which the engine rotor is mounted, which most often happens after the summer pump downtime. ALPHA1 L pumps use a ceramic shaft, which reduces its susceptibility to blocking. However, in the event of such a situation, the ALPHA1 L pump uses a simple solution, proven in traditional UPS circulation pumps - the shaft is unblocked mechanically. This method is usually effective and can be performed by both the installer and the user.

Photo 7. Unblocking the ALPHA1 L pump shaft: 1 – turn off the power supply,

2 – closing the shut-off valves, 3 – pressing and turning the unlocking screw with a screwdriver

The ALPHA1 L pump combines the features of traditional circulation pumps that have been installed in home heating systems for decades, but also successfully uses modern technologies. As a result, the main advantages of this pump are:

- simple selection of control characteristics using one button on the control panel,

- separate types of regulation dedicated to the radiator installation and underfloor heating,

- possibility of external pump control with PWM signal,

- easy and effective way to unblock the pump shaft,

- high energy efficiency and low noise level,

- signaling of correct pump operation and alarm states on LED indicators,

- Grundfos GO app allows you to determine the optimal settings and estimate savings when replacing an old pump with an ALPHA1 L

Photo 8. The ALPHA1 L circulation pump is covered by a five-year warranty.

Zbigniew Waskiewicz

External Expert

Grundfos Pumps Sp. z o. o.

ALPHA1 L – basic technical data

| Max. efficiency | 3.6 m³/h |

| Max lifting height | 6.5m |

| Max. liquid temperature | 95°C |

| Max ambient temperature | 55°C |

| Max system pressure | 10bar |

| Max viscosity | 10mm²/s |

| Power consumption | 4 - 60 W |

| Sound pressure level | <32dB(A) |

| IP protection class | X4D |

| EEI indicators | ≤ 0.20 |