Time relays in installations are functional and practical solutions that facilitate the automation of device operation, allow for time control of lighting. What tasks do time relays perform, where are they used and how to properly install them?

Check out F&F at the Onninen wholesaler

The Role of Time Relays in Electrical System Automation

In electrical systems, the installation of time relays allows for the automation of process operation. Their basic task is to implement time functions, including mainly switching devices on and off after a specified time, including cyclic control of the operation of electrical devices.

In electrical systems, the installation of time relays allows for the automation of process operation. Their basic task is to implement time functions, including mainly switching devices on and off after a specified time, including cyclic control of the operation of electrical devices.

The mechanism of operation of time relays is based on the appropriate programming of elements. The most important parameter is the time after which a set cycle of operation is performed. The relay is responsible for switching the circuit on or off, thereby starting or switching off the devices operating in a given system.

A major advantage of time relays is very precise control, based on the automation of operation. Programming the elements allows to ensure continuous operation of processes by starting devices at specific moments. Thanks to time relays in the company, you can ensure the synchronization of activities.

Overview of the F&F time relay offer

Depending on the requirements of a given installation, different types of time relays are used, which can be used in both home automation devices and advanced industrial systems.

Depending on the requirements of a given installation, different types of time relays are used, which can be used in both home automation devices and advanced industrial systems.

F&F's offer includes time relays:

- aversive and reversive;

- single-function and multi-functional;

- cyclical;

- universal.

In the context of energy management, heating systems, or in industry, programmable time relays are often used, allowing to set the on and off time, in accordance with the specifics of a given system. Thanks to this, the electrical devices operating in it are reliable and do not require constant human supervision. Automatic control using properly matched time relays ensures safety against damage and failures

Application of F&F time relays in practice

In practice, the use of F&F relays allows for the optimization of the operation of electrical installations and lower energy consumption. They are ideal for controlling ventilation or lighting inside and outside the building. Time relays can also be used in heating and power supply systems. In the former, they are responsible for controlling radiators, while in the latter, they allow for compensating errors that occur as a result of high clock frequency.

Time relays are used in manufacturing companies. They enable automation of selected processes. Properly programmed elements control the switching on and off of machines used in the production process, in accordance with the needs of the process being implemented.

F&F Time Relay Installation and Configuration Guidelines

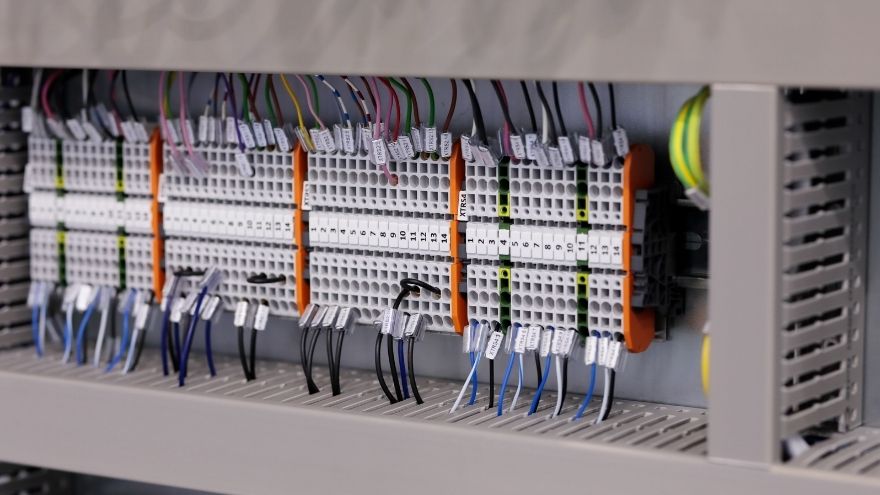

Time relays operate independently of the user, allowing for the automation of many processes. In order for the entire system and the devices in it to operate correctly, the relays must be properly installed. Among other things, a TH35 DIN rail will be needed. The installation itself is not complicated, because the relay is placed on the rail using latches located in its housing.

Time relays operate independently of the user, allowing for the automation of many processes. In order for the entire system and the devices in it to operate correctly, the relays must be properly installed. Among other things, a TH35 DIN rail will be needed. The installation itself is not complicated, because the relay is placed on the rail using latches located in its housing.

The next step is to connect the power supply, according to the diagram:

- connecting the phase (L) and neutral (N) wires to terminals 1 and 3 on the relay housing, respectively;

- connecting the receiver phase wires to terminals 4 or 7 of the relay;

- connecting the phase wires of the power line to terminals 5 or 8.

Once the power is connected, you can start configuring. In time relays, it is most important to set the appropriate functions in time. The operating time is set by special switches located on the relay.

After connecting the relay in the system, it is necessary to check its correct operation. It is important that testing is carried out in the conditions in which it will operate on a daily basis. In this way, its reliability can be determined, which is important for the safety of the devices.