The main cause of time loss when building control and switchboard cabinets is the cabling of switching and automation devices. Control cabinet designers have three connection technologies at their disposal. Most control devices are connected using screw terminals. Many users are accustomed to this method - they know with what force and torque they tightened the clamp. The other two options are Cage Clamp spring clamps and Push-in plug-in clamps. Both ensure safety and reduce workload. Today we will focus on this last option.

Read on to find out:

- what contact connection technologies are available,

- what are the features of each of them,

- what is the advantage of Push-in plugs over other solutions.

Time is money - this old truth holds true in many areas of life, and wiring a control cabinet is no exception. Choosing the right connection technology is one way to optimize this process. Thanks to Push-in plug-in terminals , wiring devices is not only quick and easy, but also safe. These types of terminals ensure efficient installation and offer benefits at all stages of the life cycle of switchgear or automation devices.

Full freedom of choice

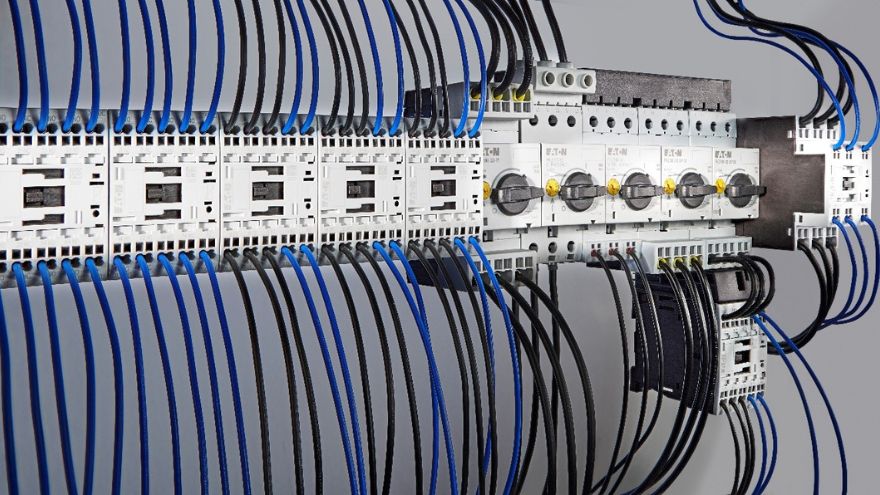

Control cabinet builders and machine, switchgear and panel manufacturers now have freedom of choice when it comes to connection technology , as top manufacturers such as Eaton offer components with a variety of terminal technologies. International approvals, supply voltage, mounting options and even the size or dimensions of the base - all these factors are now independent of the choice of connection technology.

Check out the Eaton product range from the Push-in series

Comparison of ease of use of different power terminal options

However, there are differences during installation, especially in terms of wiring costs, depending on the terminal technology used. Screw terminals are still the most commonly used connection technology for motor starters. However, their use complicates the wiring process because the correct tightening torque must be applied for each type and size of terminal. During installation, the installer must therefore change the torque or use a different tool each time.

However, there are differences during installation, especially in terms of wiring costs, depending on the terminal technology used. Screw terminals are still the most commonly used connection technology for motor starters. However, their use complicates the wiring process because the correct tightening torque must be applied for each type and size of terminal. During installation, the installer must therefore change the torque or use a different tool each time.

Cage Clamp spring terminals make wiring much easier because only one tool, usually a standard screwdriver, is required to connect and disconnect wires . However, the installation of such clamps is not without risk - the user may confuse the clamp hole with the socket of the working tool or use the wrong tool, causing irreversible damage to the spring. A screwdriver that is too small will not open the connection completely, so the specified nominal cross-section will not be possible. Especially in the case of flexible cables, such as a cord without ferrules, this may lead to problems with individual wires breaking off, which will negatively affect the electrical operating parameters.

Easy installation with Push-in technology

Compared to Cage Clamp screw and spring terminals, Push-in plug-in terminals are the only connection technology that allows for tool-free assembly , although provided that rigid cables are used or that the cable ends have been treated, e.g. with ends with sleeves. In such cases, the cable can be inserted directly into the terminal without the use of tools, which means that it can be connected with one hand.

To verify the extent of efficiency gains during the cabling process, Eaton teamed up with HPS (Hanseatic Power Solutions). HPS designs and manufactures switchboards and control systems for industrial, construction, marine and offshore applications. The test set consisted of ten contactors, each equipped with screw, Cage Clamp and Push-in terminals. Each type of contactor had to be connected to a total of 100 terminal points using crimped wires with cross-sections ranging from 1 to 2.5 mm². In six tests, each performed by a different employee, the time needed to connect the cables was recorded and averaged.

Result: comparison of Push-in technology with screw connections showed a time saving of 50% . Even compared to the spring clamp, HPS was able to determine time savings of 40% thanks to the Push-in technology.

Transport and commissioning

Once the control cabinet is wired, it must be delivered to the customer. During transportation, the components will be exposed to shock and vibration. Especially in the case of bolted connections, it is often recommended to tighten the connections during commissioning, which generates significant costs and time. With push-in plug-in terminals, start-up time is reduced to a minimum, as this type of terminals can withstand higher pull-out forces than conventional spring-loaded terminals while being highly resistant to shock and vibration.

Once the control cabinet is wired, it must be delivered to the customer. During transportation, the components will be exposed to shock and vibration. Especially in the case of bolted connections, it is often recommended to tighten the connections during commissioning, which generates significant costs and time. With push-in plug-in terminals, start-up time is reduced to a minimum, as this type of terminals can withstand higher pull-out forces than conventional spring-loaded terminals while being highly resistant to shock and vibration.

To confirm this, I²PS, an independent testing laboratory, conducted a test to see how various Eaton connection technologies behave under the influence of vibration. The result: the constant spring force of the Push-in plug-in terminals ensures long-term secure connections , which is why they also meet the vibration and vibration resistance criteria according to IEC 61373/10.2011. So there is no need to check or tighten the connection screws later.

Check out the Eaton product range from the Push-in series

Maintenance-free connections

To ensure safe operation for many years, switching equipment and automation systems must be regularly serviced , and the time and workload depend largely on the type of connection technology used. Screw terminals should be tightened regularly as the clamping force decreases over time due to current conduction in the copper conductor. Screw terminals should be checked more frequently if they are exposed to vibration , which can cause the connection to loosen, which in turn increases contact resistance and therefore the risk of fire. On the other hand, conventional spring and push-in terminals are considered maintenance-free.

Proven reliability

Additionally, Eaton commissioned I²PS to test the reliability of the electrical connections of the Push-in plug-in terminals. In this process, the push-in terminal control device was continuously exposed to salt spray for several days. The results showed that this extremely corrosive environment did not cause any significant changes in contact resistance . Confirmation was obtained that the Push-in plug-in terminals enable a reliable, gas-tight electrical connection even in difficult conditions.

The I²PS facility also measured the temperature rise in the Push-in terminals and screw terminals. The test was carried out during three-phase operation while simultaneously measuring the temperature at the main terminals of the motor starter protection. It showed that the temperature rise for plug-in terminals was the same as for screw terminals , and in some cases even lower.

The third test confirmed the high mechanical safety of the Push-in technology. For this purpose, the pull-out forces of Push-in spring clamps and conventional spring clamps were measured. The test was carried out on a 1.5 mm² wire with a ferrule, which was connected to two contactor terminals - one equipped with Push-in technology and one equipped with spring technology. The wires were subjected to a continuous increase in force until they were pulled out of the clamp. While with a conventional spring-loaded terminal the wire could be pulled out of the terminal at just 56 N, with the push-in terminal this was only possible at 173 N. This is well above the 35 N required by the standard, which means that push-in terminals -in offer exceptionally high mechanical safety. The difference in favor of the plug-in terminal is due to its design - up to a certain limit, the clamping force on the cable increases in proportion to the force applied to the cable.

Suitable for international use

Push-in technology is approved for use worldwide. It is important, however, that the terminals are approved for use as intended (especially in relation to UL applications), which also includes compliance with regulations regarding appropriate AWG (American Wire Gauge) cross-sections. Contactors require special approval for certain applications, such as controlling compressors, elevators or heating systems.

Push-in technology is approved for use worldwide. It is important, however, that the terminals are approved for use as intended (especially in relation to UL applications), which also includes compliance with regulations regarding appropriate AWG (American Wire Gauge) cross-sections. Contactors require special approval for certain applications, such as controlling compressors, elevators or heating systems.

If IEC motor starter protectors are to be used in UL applications, they require UL Type E approval. For this purpose, devices must usually have appropriate accessories, such as baffles, that ensure compliance with regulations that impose the appropriate phase spacing required for certification. This is the only way to avoid the need for additional short-circuit protection . The use of UL Type E approved devices is therefore a basic requirement for European manufacturers wishing to offer uniform control cabinet designs worldwide.

Easy device replacement

A device reaches the final stage of its life cycle when it becomes defective and requires replacement. When it becomes necessary, plug-in terminals also reveal their advantages over other types of terminals. To remove the cable, simply open the clamping spring by pressing (usually by inserting a regular flat-head screwdriver). Overall, using push-in switchgear significantly reduces downtime to replace damaged devices compared to other connection options.

Push-in clamps are becoming more and more popular

Currently, there is a clear trend towards the increasing use of plug-in technology. The benefits of time savings, tool-free operation and contact reliability are simply too great to ignore. In addition, flexible cables with terminals are increasingly used in cabling, which is an additional advantage of Push-in terminals . No other side of the coin was found - the joining technology described here has numerous advantages over other solutions, and at the same time it is devoid of any disadvantages that would disqualify it or even require considering the validity of its use. Eaton therefore predicts that push-in terminals will replace conventional spring terminals within a few years , while taking market share from screw terminals.