Cable crimping is the process of connecting the ends of cables or wires with appropriate connectors or connectors using a special tool called a cable crimper. What is a sleeve press, how does it work and what variants should you choose? You will find out in this article!

Check out the ferrule presses at the Onninen wholesaler

What is a sleeve press?

A ferrule press is a precise device that allows you to make precise cable connections. The device, also called a ferrule crimper, is one of the basic tools of every electrician. In practice, there are different variants of devices - manual, hydraulic and electric, but manual presses, using only muscle power, are used for cables with smaller cross-sections.

Using a press allows you to make very solid and durable connections, and after pressing, the cables are resistant to pull-out attempts and accidental damage. Many of the devices are additionally equipped with the ability to adjust the pressure force, which allows you to adapt the operation of the device to the variant (thickness, number of wires) of the cable. The cable pressing technique is definitely more advantageous than classic soldering - it allows you to reduce expenses and speed up work. A big advantage is also the elimination of the problem of releasing contact points in soldered fragments, which deteriorated the quality of transmission over time. Depending on the method of use, the Onninen installation wholesaler offers various variants of devices - for flat contacts, optical fibers, insulated terminals, coaxial connectors and many others.

Using a press allows you to make very solid and durable connections, and after pressing, the cables are resistant to pull-out attempts and accidental damage. Many of the devices are additionally equipped with the ability to adjust the pressure force, which allows you to adapt the operation of the device to the variant (thickness, number of wires) of the cable. The cable pressing technique is definitely more advantageous than classic soldering - it allows you to reduce expenses and speed up work. A big advantage is also the elimination of the problem of releasing contact points in soldered fragments, which deteriorated the quality of transmission over time. Depending on the method of use, the Onninen installation wholesaler offers various variants of devices - for flat contacts, optical fibers, insulated terminals, coaxial connectors and many others.

You can read more about ferrule crimping machines in this article: Reliability and durability: ferrule crimping machine

How does a sleeve press work?

The ferrule press is not a complicated device in construction and operation, but it allows for perfect protection of the electrical installation, so that it is tight and does not pose a threat. In functional terms, the operation of the ferrule press is similar to soldering, but it is a more effective solution that allows you to reduce potential problems resulting from soldering, and additionally allows you to significantly reduce the connection time and reduce costs. Their appearance resembles traditional pliers, but their purpose is completely different. The device allows you to connect uninsulated wires, both single- and multi-core, with a selected terminal.

You can read more about soldering guns and soldering in this article: How to choose the right soldering iron?

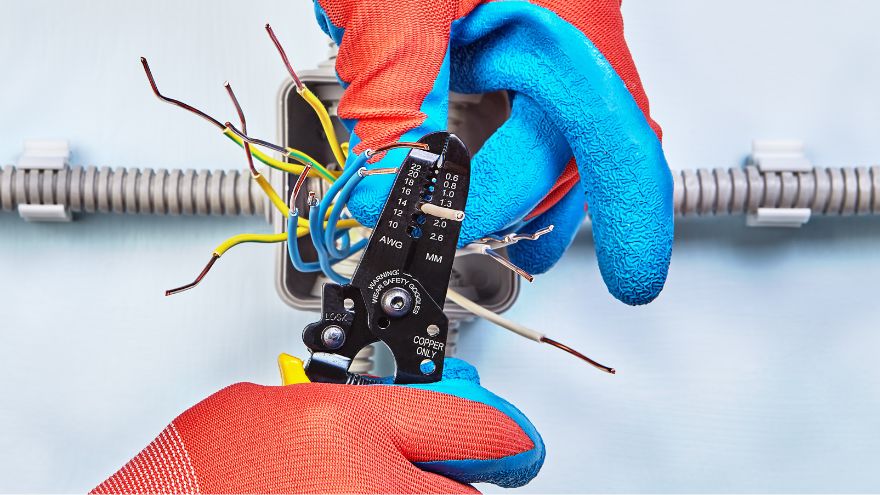

The detailed method of use depends primarily on which variant you use. The type of tips used is also important. The first step is to remove the insulation from the wire. You can use special devices called insulation strippers, although an ordinary wallpaper cutter or a regular knife can also be helpful. However, remember that you need to be especially careful in such a situation. The insulation should be removed from the wire at the same length as the sleeve will be placed. Place the end of the cable in the crimper and then tighten the handle of the device. After completing the task, it is necessary to check the tightness of the sleeve attachment so that the whole thing is safe and does not pose a potential threat. In the case of automatic crimpers, work is much easier because the hole automatically adjusts to the length of the tip placed in it.

The detailed method of use depends primarily on which variant you use. The type of tips used is also important. The first step is to remove the insulation from the wire. You can use special devices called insulation strippers, although an ordinary wallpaper cutter or a regular knife can also be helpful. However, remember that you need to be especially careful in such a situation. The insulation should be removed from the wire at the same length as the sleeve will be placed. Place the end of the cable in the crimper and then tighten the handle of the device. After completing the task, it is necessary to check the tightness of the sleeve attachment so that the whole thing is safe and does not pose a potential threat. In the case of automatic crimpers, work is much easier because the hole automatically adjusts to the length of the tip placed in it.

Pressing machines for sleeves at the Onninen wholesaler

The Onninen electrical wholesaler offers many models of cable crimpers that will prove useful in the work of every professional. Various variants of devices are available, used depending on needs. One of the products is a press for Haupa sleeves 0.5-16 mm , prepared by HAUPA . The device is exceptionally solid and durable. The square clamp makes the press very stable in your hand, which affects the precision of the connection. This model is intended for making sleeve connections with a cross-section ranging from 0.5-16 mm.

An alternative solution is the Haupa 10-35mm manual sleeve press with a trapezoidal clamp . It allows you to make insulated and non-insulated sleeve terminals. The operating range of the device is from 10 to 35 mm. The big advantage here is durability and solid construction made of tool steel, with a comfortable PVC handle. The press also allows you to strip insulation from cables.

An alternative solution is the Haupa 10-35mm manual sleeve press with a trapezoidal clamp . It allows you to make insulated and non-insulated sleeve terminals. The operating range of the device is from 10 to 35 mm. The big advantage here is durability and solid construction made of tool steel, with a comfortable PVC handle. The press also allows you to strip insulation from cables.

Haupa 6-16mm manual collet presses with a trapezoidal clamp are also very popular. Solid construction and excellent quality materials from which it is made guarantee solidity and durability. The device is adapted to work with cables with a cross-section of 6-16 mm. The solution will work great even in hard-to-reach places. This model is not equipped with an automatic return mechanism, which is a great help in many situations, as it allows you to precisely control the degree of pressure, making each execution precise and durable.