Water in industry is a fundamental raw material used, among others, as a solvent, cooling and rinsing fluid and as a clean liquid. Reusing water used in this way leads to its treatment and reuse in technological and production processes. This allows companies from the industrial sector to achieve a closed water cycle, which is a key element of a resource-efficient, sustainable and competitive raw material economy. It is difficult to imagine the future of industry without a water recovery system.

From the article you will learn...

what the industrial water recovery process is and what it involves, and what wastewater treatment solutions Grundfos offers.

Water reuse – definition and process

Water reuse allows companies from the broadly understood manufacturing and technology industries to gain a significant competitive advantage. This advantage is due to multi-level savings provided by in-house wastewater treatment, reduced water distribution costs and full plant control over the stages of production of purified water.

Water recovery in the production sector is defined as the treatment of already used water into water of a quality that allows it to be reused in various utility processes - e.g. cooling, cleaning or rinsing. Of course, the use of recovered water resources varies depending on the type of processes, sewage contamination, technology and installations, or industries.

Wastewater is recovered as part of a 5-stage process of purifying used water. During each stage, it is extremely important to monitor hydraulic parameters (flow, temperature, turbidity and TOC) and precisely control the treatment processes.

Sewage transport

The first stage in which wastewater treatment begins is the transportation of used water. Various devices are used to pump liquids, depending on its characteristics, composition and particle content. For example: stainless steel pumps are used to transport water saturated with chlorides.

Biological treatment

The next step is biological wastewater treatment. It comes down to purifying transported water using appropriate bacterial cultures. Water treatment processes depend on nitrogen content, biochemical oxygen demand (BODn) and chemical oxygen demand (COD). This process primarily involves reducing the concentration of phosphorus and nitrogen present in water. Sometimes biological wastewater treatment is combined with physical separation of water particles using membrane bioreactors.

Sewage disposal

The third stage of industrial water recovery involves discharging pre-treated wastewater into the environment in accordance with local wastewater management regulations. Most often, purified industrial water is discharged to surface water sources.

Chemical and physical treatment

If water recovery must provide a more thoroughly purified raw material, then chemical and physical water treatment is carried out by manipulating its pH.

Concentrate treatment

The penultimate stage of the industrial water treatment process is concentrate treatment. This is a complicated step that requires a lot of energy and high ion concentration. The concentrate is treated using reverse osmosis with a maximum of 3 degrees or using the crystallization process.

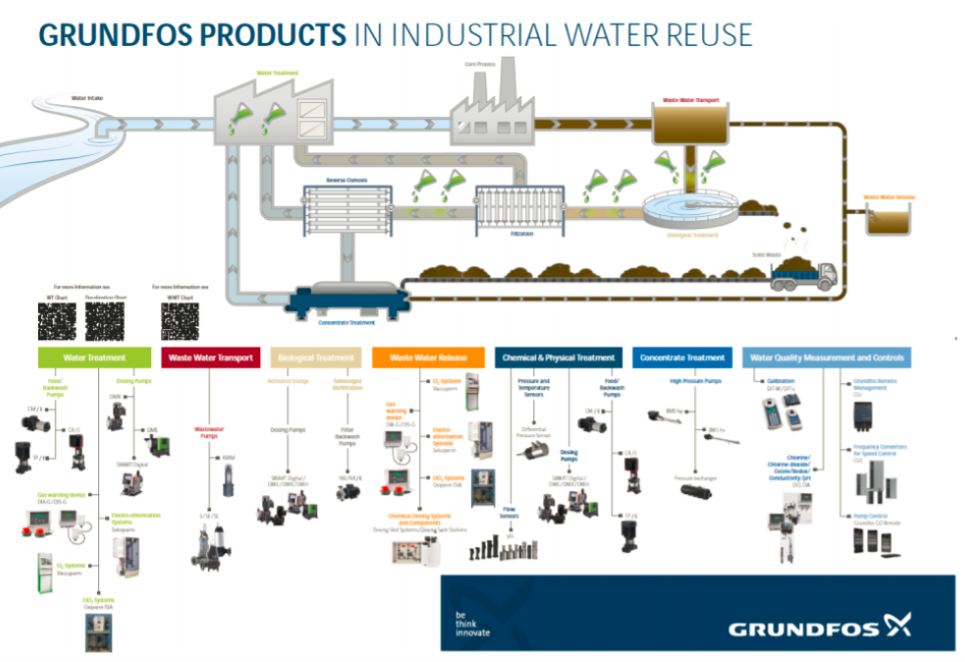

Grundfos iSOLUTIONS in water reuse

Grundfos is a Danish manufacturer of pumps and filtration systems. The company supplies the industry with modern solutions in the field of water transport and treatment. One such solution is Grundfos iSOLUTIONS. It is a holistic system consisting of modern solutions in the field of pump systems, water supply techniques, cloud connectivity and digital services, which together create an innovative and intelligent system for the holistic optimization of water production and recovery systems.

The Grundfos iSOLUTIONS offer meets the challenges posed in the ultrafiltration process to which industrial water is subjected. The main advantage of the iSOLUTIONS solution is not only effective water recovery, but also the ability to constantly monitor and modify the parameters of industrial water. It is primarily important to monitor the state of raw water and the demand for clean water.

With iSOLUTIONS solutions, industry and water recovery will never be the same. The presented system solutions are perfect not only for water recovery, but can also be successfully used to precisely regulate its parameters in technological processes, significantly reduce network operating costs, reduce downtime of water transport installations, as well as reduce the system load.

Chemicals in pre-treatment and washing

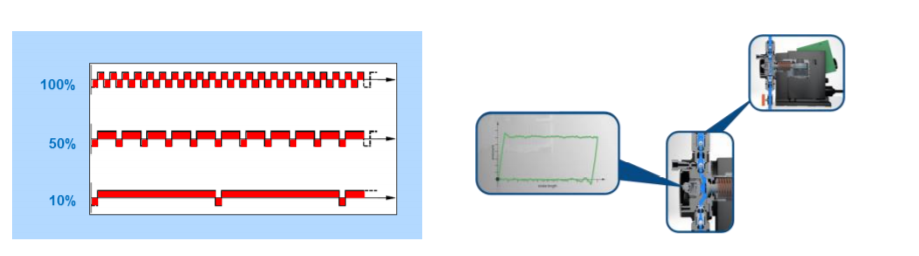

Ultrafiltration requires very precise doses of chemical additives. Modern digital dosing pumps installed, among others, in installations supplied by Grundfos, they can administer the required amount of chemicals with high precision.

Fig. Flow monitoring principle and dosing flow diagram

The diagram above shows the near-continuous dispensing flow that is delivered using stepper motor technology – even at low volumes. The integrated flow monitor allows you to control the flow and also provides information on the actual flow compared to the set point. The SMART Digital product group also includes modular pumps that guarantee easy integration with the installation.

The fourth industrial revolution is coming

Grundfos is an inseparable companion of the fourth industrial revolution. The company is able to supply a range of pumps and pump systems to ensure that the ultrafiltration (UF) system is modern in terms of reliability and cost-effectiveness and ready for the increasing demands in the water reuse process.