PXF Lighting is a Polish manufacturer of luminaires and lighting systems, providing the European market with modern solutions in the field of lighting technology. In this article, we present the most important technical parameters of LED lighting fixtures from PXF Lighting along with their discussion.

In this article you will read about:

key technical parameters of PXF Lighting LED lighting fixtures . We will discuss: the operational durability of LEDs, the decrease in luminous flux over time, the degradation and life of diodes, as well as MacAdam ellipses, SDCM, LLMF and binning.

What are you looking for?

Check out PXF Lighting products at the Onninen wholesaler

Operational durability of LED diodes

The operational durability of LEDs is one of the most important technical parameters determining the actual operating time. The operational durability of LED diodes is defined as: L80 B10 >50,000 h, which means that: during 50,000 hours of operation of the lighting fixture, the luminous flux will not be lower than 80% of the initial value, and the number of diodes that will emit the flux luminous value below 80%, will not exceed 10% all diodes from the tested production series.

Light flux decreases over time

The decrease in luminous flux over time is a parameter of LED diodes that describes the change in luminous flux during the operation of the lighting fixture . As the operating time passes, the luminous flux of the LEDs decreases. The scale of this phenomenon depends on the class of chips used.

The LED durability parameter described by PXF Lighting is presented at 90% or 80% of the nominal value. The designations used are L90 and L80 respectively. The decrease in luminous flux over time is closely related to the parameter referred to as the LED lifespan.

LED lifespan

LED lifespan is a parameter describing the operating time after which the luminous flux decreases (L factor) and the degree of degradation (B factor). LED lifespan is therefore a technical parameter directly related to the decrease in light flux over time and the degradation of LEDs.

The standard reference point is an operating time of 50,000 hours. Coefficients L and B are assigned to this period. An extended description of the operating time may cover a period of e.g. 80,000 hours. Then the coefficients will take a lower value compared to the standard description, e.g.: L60 B20 > 80,000 h.

Check out PXF Lighting products at the Onninen wholesaler

LED degradation

LED degradation is a parameter of LED diodes that describes the number of chips that, after a given period of operation, will emit a luminous flux lower than the flux indicated by the flux degradation factor L.

In other words: degradation is a parameter of a set of LEDs that describes the number of chips with a flux lower than L in a given operating time.

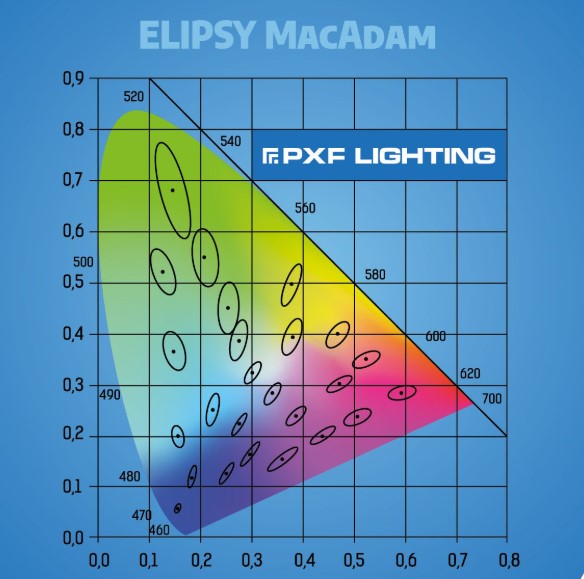

MacAdam ellipses and SDCM

The MacAdam ellipse is an elliptical region placed on the CIE chromaticity diagram. The area indicated by the diagram includes color variations indistinguishable to the human eye compared to the color inside the ellipse. SDCM (Standard Deviation Color Matching) is the standard deviation of color matching. The SDCM parameter determines the adjustment of the light color based on the MacAdam ellipse. SDCM is defined as the range of the ellipse around a perfect black body, and the smaller the ellipse, the greater the consistency of the light color. In indoor lighting, the SDCM value of 3 is most often used. Determined by the 3-fold MacAdam ellipse, it ensures a highly acceptable level of light color consistency while maintaining a favorable value for money.

Check out PXF Lighting products at the Onninen wholesaler

LLMF

LLMF (Lamp Lumen Maintenance Factor) is the level of the initial flux after 60,000 hours. The parameter determines the percentage value of the LED luminous flux after 60,000 hours of operation. In other words, LLMF is defined as the luminous flux maintenance factor of the light source.

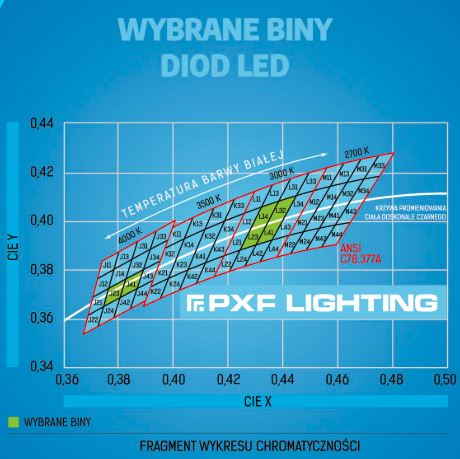

LED binning

Binding is an automated process of sorting and grouping produced LEDs based on a set set of technical parameters. The criteria for sorting and grouping LEDs are most often their brightness, color, color rendering index, and rated voltage. LEDs with specific sets of parameters that have undergone the binning process are placed in one roll for the SMD machine.