Every electrical installation must be equipped with effective protection against electric shock. According to documents issued by the International Standards Organizations (IEC and CENELEC), protection against electric shock in low-voltage installations has a three-level structure. It provides for 3 types of protection: basic (protection against direct contact), in the event of damage (protection in the event of indirect contact) and supplementary, which will operate in the event of failure or damage of previous measures and in situations of increased risk of electric shock. What is direct contact in electrical installations and what is indirect contact? And what should the correct protection look like in both cases? We explain!

Check out the anti-surge gloves at the Onninen wholesaler

Direct touch in electrical installations

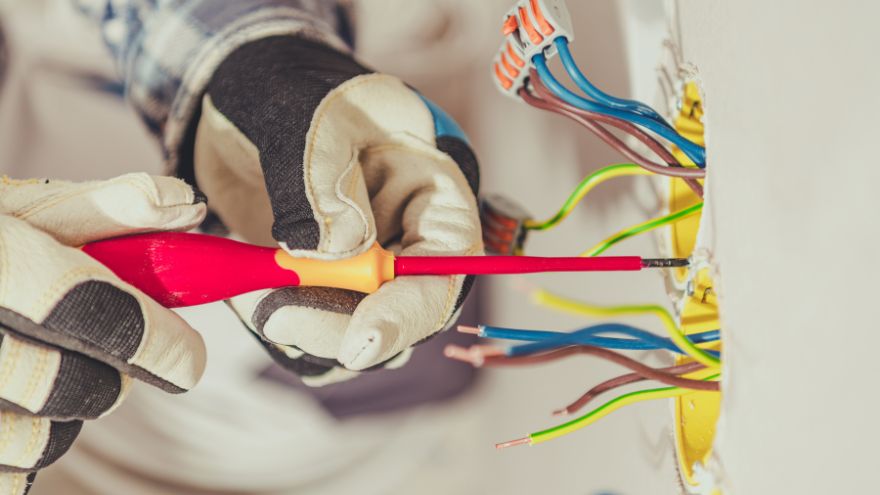

Basic protection in an electrical installation is protection against direct contact, provided by, among other things, proper insulation of live parts (basic insulation of active parts, partitions or housings). Direct contact is nothing more than physical contact with a live wire (conductive part). Basic protection measures are designed to prevent touching live parts. Touching unprotected wires can occur, for example, during amateur electrical work or as a result of insulation damage. In such situations, a 30 mA or lower operating current differential switch can protect against electric shock.

Basic protection in an electrical installation is protection against direct contact, provided by, among other things, proper insulation of live parts (basic insulation of active parts, partitions or housings). Direct contact is nothing more than physical contact with a live wire (conductive part). Basic protection measures are designed to prevent touching live parts. Touching unprotected wires can occur, for example, during amateur electrical work or as a result of insulation damage. In such situations, a 30 mA or lower operating current differential switch can protect against electric shock.

What is indirect touch in electrical installations?

As a result of damage or short circuit in the electrical installation or its incorrect execution, there is a risk of indirect contact, i.e. contact with conductive parts that are not under voltage under normal conditions. These include, for example, device housings, mounting elements or switches. Electricians, electrical engineers and other specialists performing electrical work are most at risk of electric shock as a result of indirect contact. In such situations, additional protection should be activated.

Correct protection against direct and indirect contact

Basic protection - against direct contact - is mainly based on preventing contact with live wires. Insulation of current-carrying elements is standard. Wires require the use of double insulating material and additional reinforcement of insulation. Other tools for protection against direct contact include various types of barriers, obstacles and enclosures (with an appropriate IP index), as well as barriers, cabinets and safety nets that prevent accidental access.

Additional protection (in the event of damage) – against indirect contact – prevents electric shock resulting from contact with a wire or element that should not normally be live. It consists of various types of switches that are responsible for automatic disconnection of the circuit power supply in the event of danger. The basis is the measurement of the short-circuit loop impedance (ZS), i.e. checking the effectiveness of additional protection against electric shock in the event of a failure and switching on of live parts.

Additional protection (in the event of damage) – against indirect contact – prevents electric shock resulting from contact with a wire or element that should not normally be live. It consists of various types of switches that are responsible for automatic disconnection of the circuit power supply in the event of danger. The basis is the measurement of the short-circuit loop impedance (ZS), i.e. checking the effectiveness of additional protection against electric shock in the event of a failure and switching on of live parts.

In addition, a differential switch is used in the installation. In the event of a differential current, the disconnecting device should automatically trip within a safe time. Differential switches detect much smaller leakage currents than overcurrent switches , which due to the high resistance of the human body could not trip. In addition, protection against electric shock against indirect contact is provided by using: very low safe voltage, ungrounded local equalization connections, class II protection devices, isolation of the site and electrical separation.

As mentioned in the introduction, protection against electric shock in installations can have a three-level structure. The third level is created by protection that supplements the basic protection and/or in the event of damage. Supplementary protection is used only in specific cases.

The elements included in it prevent electric shock in the event of failure of basic protection measures and/or damage, as well as in conditions of increased risk. The elements of supplementary protection are differential-current circuit breakers and additional equalization connections, which connect all accessible conductive parts and extraneous conductive parts.

The elements included in it prevent electric shock in the event of failure of basic protection measures and/or damage, as well as in conditions of increased risk. The elements of supplementary protection are differential-current circuit breakers and additional equalization connections, which connect all accessible conductive parts and extraneous conductive parts.

In addition to the use of the above technical means of protection against direct and indirect contact, numerous non-technical measures are of great importance for the safety of users of electrical installations. These include educational activities or the use of effectively insulated tools.

We encourage designers of electrical installations, electrical installers, owners of electrical shops and other professionals to familiarize themselves with the offer of our wholesaler. The assortment includes modern electrical equipment , including modular equipment (including surge arresters ), control and measurement equipment. Onninen's sales and technical advisors provide free telephone and e-mail support.