A solution combining the advantages of underfloor and radiator heating is increasingly used in our country. Thanks to this, users gain high thermal comfort, even when the outside temperatures are extremely low. At the same time, it is a very convenient system to use. If you perform this type of installation for your clients, check out our guide on pump groups!

From this article you will learn:

- how the pumping and mixing group works,

- what elements does the pump and mixing group consist of,

- how to select a pumping and mixing group for underfloor heating.

What are pump groups?

A pump group is a device that combines the functions of a pump and a valve. It is the most popular and effective way to divide temperatures between underfloor heating and radiator heating . For such a system to operate at maximum efficiency, it is necessary to provide a lower temperature for the former and a higher temperature for the latter. The device mixes media from both circuits for surface installation.

It is worth considering the installation of a pumping and mixing group already at the building design stage. Taking it into account allows you to adapt the electrical installation to power the pump. This also avoids the problem of mismatching the size of the cabinets to the manifolds.

The pump group is a guarantee of obtaining the desired temperature of the heating medium and maintaining it at a constant level. It is used where it is necessary to provide a medium with appropriate pressure and a temperature lower than the temperature of the medium leaving the heat source.

Check Valvex pumping and mixing groups

Advantages of using pump groups

The benefits of using pumping and mixing groups can be multiplied. The most important advantages certainly include:

- saving time,

- saving space,

- better access to installation elements in the boiler room,

- more attractive visual effect,

- increased installation reliability (reduction in the number of connections between components).

Types of pumping and mixing groups

Pumping and mixing groups are divided primarily into models intended for central installation in the boiler room and models for installation at manifolds. Pump groups intended for central installation are usually equipped with manual mixing valves for automatic operation, which require actuators and appropriate control devices. In the case of groups mounted at manifolds, thermostatic mixing valves are usually used.

Pumping and mixing groups are divided primarily into models intended for central installation in the boiler room and models for installation at manifolds. Pump groups intended for central installation are usually equipped with manual mixing valves for automatic operation, which require actuators and appropriate control devices. In the case of groups mounted at manifolds, thermostatic mixing valves are usually used.

Construction of pump groups

Pump groups with a mixing valve consist of several elements performing similar functions. We are talking about parts such as:

- three-way or four-way valve allowing regulation of the temperature of the heating medium. Depending on the type of pump group, these may be mixing valves equipped with an actuator or thermostatic valves.

- thermometer indicating the temperature of the supply and return water

- circulation pump responsible for mixing hot water with cooled water and proper circulation of the medium in the heating loops.

In sets with a mixing valve, the heating medium coming from the heat source is mixed with the cooled medium returning from the surface heating installation. In this way, the medium at a reduced temperature enters the installation.

Which solution should I choose?

When choosing a pump group, you should pay special attention to installation. As we mentioned above, it is worth considering whether it is better to install the device locally or centrally. The first variant will work well when the underfloor heating is powered by one distributor. By mounting the group right next to it, you will avoid an additional riser in the installation, making the entire process easier and cheaper for your client. The second solution is intended for buildings where surface heating is provided on more than one level and is powered, for example, by two manifolds. Then the pump group should be located in the boiler room, on a separate riser.

Pumping and mixing groups from Valvex

You will choose a centrally mounted group when:

- you are installing in a new building,

- a sufficiently large boiler room is available,

- it is possible to install a device controlling the valve operation or the heat source is equipped with such an element.

A group mounted next to the manifold will work better when:

- you are modernizing the installation in an old building,

- there is no space for additional equipment in the boiler room,

- no installation of a device controlling the operation of the mixing valve is planned.

Exchange benefits in the new OnnTop loyalty platform!

If you intend to install a mixing valve and a pump in the boiler room, try to select a group taking into account the possibility of installing the device in this room. For example, choose PROFFmix from Valvex. Thanks to this solution, the set's components will not generate noise in assembly cabinets that would have to be located in living rooms. Moreover, in such a situation, it is easier to connect electrical cables responsible for integrating the control of mixing systems and circulation pumps to the device. It is also an aesthetic solution, because large assembly cabinets would negatively affect the appearance of the interior. Your customers will surely appreciate such amenities.

If you intend to install a mixing valve and a pump in the boiler room, try to select a group taking into account the possibility of installing the device in this room. For example, choose PROFFmix from Valvex. Thanks to this solution, the set's components will not generate noise in assembly cabinets that would have to be located in living rooms. Moreover, in such a situation, it is easier to connect electrical cables responsible for integrating the control of mixing systems and circulation pumps to the device. It is also an aesthetic solution, because large assembly cabinets would negatively affect the appearance of the interior. Your customers will surely appreciate such amenities.

Pump groups mounted directly next to the manifolds are equipped with thermostatic mixing valves. In this case, no device controlling the valve operation is required, and the thermostatic valve insert is responsible for the proper operation of the valve. The required temperature of the medium is set on the mixing valve knob. The valve operation, independent of external control, allows the manifold to be placed far from the boiler room, providing only the power needed to operate the pump. Valex will recommend selecting a group from the PROFFPLUS series.

Pump groups mounted directly next to the manifolds are equipped with thermostatic mixing valves. In this case, no device controlling the valve operation is required, and the thermostatic valve insert is responsible for the proper operation of the valve. The required temperature of the medium is set on the mixing valve knob. The valve operation, independent of external control, allows the manifold to be placed far from the boiler room, providing only the power needed to operate the pump. Valex will recommend selecting a group from the PROFFPLUS series.

Selection of the pump group

When selecting pump groups for a heating installation, you should take into account the total length of the underfloor heating loop and the design of flows in individual loops. These parameters must be compared with the capabilities of the pump and valve of the mixing group. These elements must be able to balance the pressure losses in the system.

Therefore, select the pump group based on the required parameters of the pump and mixing valve. It will help you define:

- required pump lifting height,

- required KVS coefficient of the mixing valve.

This way you will avoid installing a valve that is too small or oversized.

The issue of selecting a pump group for a floor installation may seem somewhat complicated. Fortunately, the manufacturers of these devices use a system that makes this task much easier. They design sets designed for specific heating surfaces. They are determined by taking average standard parameters for underfloor heating. For simple installations, you can therefore use the manufacturers' recommendations. However, if you are dealing with non-standard systems, calculate the required parameters yourself.

Check Valvex pumping and mixing groups

PROFF PLUS pumping and mixing group from Valvex

If you are looking for energy-saving solutions for your customers, you need to get to know the Valvex brand range. It is one of the leading manufacturers of bathroom and kitchen faucets, as well as fittings for water, gas and central heating installations. This Polish company is well known to contractors and users all over the world - from the European Union, through the Middle East, to North and South America. It is synonymous with high quality, reliability and attractive design.

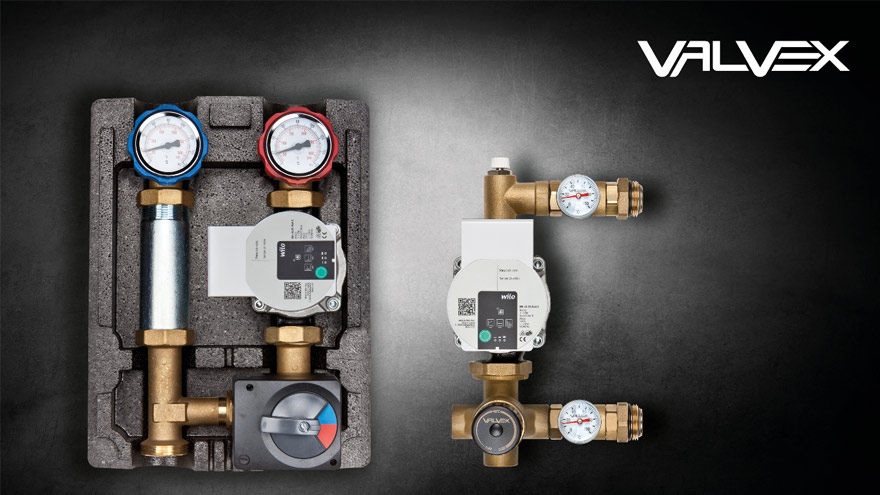

Among the numerous Valvex products, we recommend the PROFF PLUS pumping and mixing groups . This is a system solution that guarantees optimal temperature of the heating medium in the underfloor heating installation. Its mixing system is based on the innovative TERMOCONTROL 4-way valve. The pump used here is characterized by smooth regulation of rotational speed, and the innovative connection system significantly facilitates the installation of the device. Thanks to the nuts, you can easily correct the thermometer settings and tighten the set to the manifold. The PROFF PLUS pump group is a guarantee of tightness and reliability!

Check out the Valvex range, available from Onninen, and buy pumping and mixing groups, thanks to which you will provide your customers with efficient and energy-saving underfloor heating!

Do you have questions about the industry? Join the Świat Instalacji group!