CONTROLMIX 4-way mixing valves

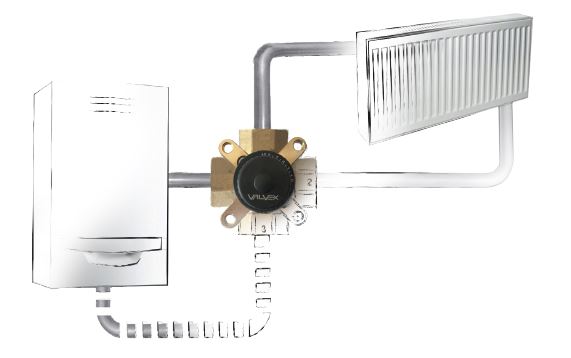

A solid fuel boiler is a popular source of heat energy in our home. Sometimes it is also an additional source of heat in the so-called integrated heating system. When deciding on such an installation, we often use mixing valves. Their task is to regulate the supply temperature of the heating system, as well as the return temperature to the boiler. Too low a temperature of the heating medium returning to the solid fuel boiler causes water to precipitate on its walls in the combustion chamber. Over the years, this may lead to corrosion of the walls of the water jacket and thus rapid wear of the device.

Schematic diagram of a 4-way Controlmix valve in an installation with a solid fuel boiler

See Controlmix valves at the Onninen wholesaler

The appropriate temperature of the water medium at the boiler return eliminates this problem, therefore the solution to this problem is the Valvex 4-way mixing control valve . The CONTROLMIX valve , by increasing the return temperature, protects the boiler against condensation and, as a result, against corrosion of the boiler sheet, thus extending its service life and increasing the efficiency of combustion of the supplied fuel.

Valvex 4-way rotary mixing valves are available in 5 basic dimensions

– from DN20 to DN50.

| Dimension | Work parameters |

| DN20 | PN 10, – 10ºC÷110ºC, Kvs 6.3 (m³/h) |

| DN25 | PN 10, – 10ºC÷110ºC, Kvs 12 (m³/h) |

| DN32 | PN 10, – 10ºC÷110ºC, Kvs 16 (m³/h) |

| DN40 | PN 10, – 10ºC÷110ºC, Kvs 25 (m³/h) |

| DN50 | PN 10, – 10ºC÷110ºC, Kvs 40 (m³/h) |

Particularly noteworthy are the slip inserts (PTFE) , placed between the valve body and the valve body. This unique idea from VALVEX guarantees low valve opening/closing torque (<1 Nm) and protection against scaling.

See Controlmix valves at the Onninen wholesaler

CONTROLMIX 3-way mixing valves

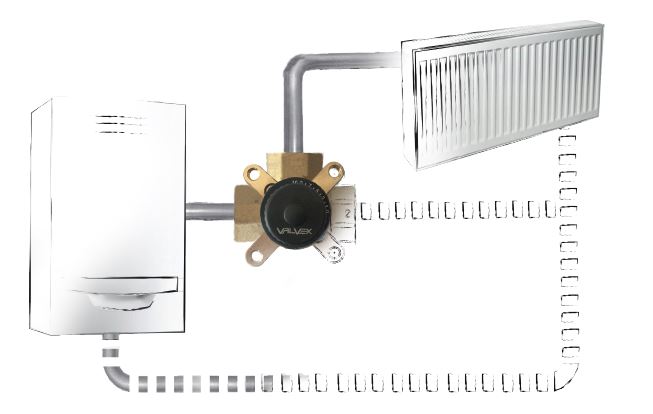

3-way mixing valves are mainly used in low-temperature installations. Their purpose is to prepare the appropriate temperature of the heating medium for underfloor heating. They are mounted before

circulation pump. The properly mixed medium is sucked in by the pump and fed to the receiver. Temperature regulation is much more precise if we install a mixing actuator to such a valve. The Valvex brand offers two actuators:

- V-MIX STM 10/230 actuator – has a built-in constant temperature controller,

installed sensor and plug. The sensor, mounted as far as possible from the mixing valve, monitors the set mixing temperature. The set mixing temperature is set directly on the actuator. - V-MIX ST 10/230 actuator – requires an external regulator. Valvex's offer includes the V-THERM controller, equipped with the function of weather control, room thermostat control and control

constant temperature. The choice of function depends on the installation design. Other regulators available on the market can also be used or used

regulators installed on solid fuel or gas boilers.

Schematic diagram of the Controlmix 3-way valve in an installation with a solid fuel boiler

The rotational power of the actuators is up to 10 Nm. This guarantees reliable and smooth opening and closing of the valve, even after a long period of non-use of the installation

(summer period). Valvex 3-way valves come in sizes from DN20 to DN50. They are characterized by an appropriate flow coefficient for a given size. They are made of high-quality materials, which guarantees long service life.

| Dimension | Work parameters |

| DN20 | PN 10, – 10ºC÷110ºC, Kvs 6.3 (m³/h) |

| DN25 | PN 10, – 10ºC÷110ºC, Kvs 12 (m³/h) |

| DN32 | PN 10, – 10ºC÷110ºC, Kvs 16 (m³/h) |

| DN40 | PN 10, – 10ºC÷110ºC, Kvs 25 (m³/h) |

| DN50 | PN 10, – 10ºC÷110ºC, Kvs 40 (m³/h) |

The size of the mixing valve plays an important role because oversizing or selecting too small a size may lead to incorrect operation of the heating circuit or its complete failure (no heat, inability to maintain the desired temperature, inappropriate operation of the actuator).

For the valve to fulfill its function in the installation, the flow rate, valve authority and then the Kvs value, according to which the valve size is selected, must be determined.