Gas heating is currently one of the most popular choices among consumers. It is cheaper than electric heating and more environmentally friendly than that using solid fuel boilers. Construction law regulations specify how a gas installation should be constructed and operated. Due to the flammability and risk of explosion of the medium present in the installation, special attention should be paid to compliance with the requirements contained in the standards and technical conditions. We can all imagine the consequences caused by unreliable design or construction of a central heating installation. In today's article, we refer to the technical conditions that gas installations are subject to and advise which gas valve to choose. We invite you to read!

From the article you will learn:

- how a safe gas installation should be designed and constructed,

- what are the types of gases supplying gas installations,

- how the gas installation is constructed

- which ball valve is best to use.

Check out the offer of gas valves at the Onninen wholesaler

Natural gas and liquefied petroleum gas

Gas is one of the conventional energy fuels. Residents of single-family houses use gas to heat the building and heat domestic hot water (DHW). It is also used in the kitchen, where it becomes an alternative to electric stoves.

Depending on the type of gas supplying the installation , the systems can be divided into:

- gas installations powered by natural gas from the network,

- gas installations powered by liquid gas from a tank.

Liquid gas installations are powered by liquid gas stored in a tank outside the building. It is recommended to use pure propane as a gas for heating the building. The gas is stored in liquid form, but it flows into the installation in the form of gas. Due to the type of fittings used, this installation, in the part behind the shut-off valve, does not differ from the natural gas installation.

Natural gas is transported through pipelines forming gas networks. Gas is supplied to buildings through gas connections. Due to the continuity and costs of the fuel supplied, it is the most optimal option for gas-powered installations. However, this solution is not available for areas where gasification is unprofitable or impossible to implement.

Gas installation at home - basic information

A gas installation for a single-family house must have two characteristic features: it should be designed to meet safety requirements and it must enable easy maintenance work . It is a system of pipes, devices and fittings that are located both outside and inside the building.

The installation is powered by natural gas

The boundary between the network and the gas installation is the main gas tap. Currently, in single-family construction, there is an obligation to place the main tap with a gas meter and a possible reducer at the property boundary, which means that part of the home gas installation is laid in the ground. It should also be possible to isolate the installation located in the building from the installation located in the ground, using a shut-off valve.

The installation is powered by liquefied gas

In a liquefied gas installation, the gas tank is located on the property being used. In this case, there is no point where the network and installation connect to each other. The installation is divided into 2 parts: one - leading from the tank to the main shut-off cock, which, depending on the method of gas collection from the tank, contains various regulatory elements and the second one connecting the shut-off cock with the installation inside the building. From the point of view of installation inside the building, the system does not differ in terms of the fittings used from those used in natural gas installations.

Check gas valves at the Onninen wholesaler

Designing a gas installation - what should you remember?

In most cases, it is no longer necessary to obtain a building permit for the installation of a gas installation. However, it is necessary to have a design that must be made by an authorized designer.

The gas connection should be routed through the shortest and simplest route possible. It must run perpendicular to the border of the plot, and the distance from other elements of the plot's infrastructure must be maintained. The diameters of the pipes are selected by an authorized designer depending on the number of gas receivers. The passage through the partitions of the external wall of the building should not be lower than 0.5 meters from the basement floor in the casing pipe. Gas pipes in the house must be routed on the surface - using special clamps. Appropriate distances must be maintained between electrical installation cables - natural gas cables must be at least 10 centimeters above the electrical cables, while liquefied gas cables must be located below the electrical installation.

Please remember that the regulations only allow gas to be transmitted through plastic pipes in the case of pipelines laid in the ground. The installation should enter the building below the ground surface. Installations inside buildings should be made of steel or copper. In the case of multi-family buildings, gas installation conduits should be made of steel pipes connected by welding on a section from 0.5 m in front of the outer wall of the building to the shut-off taps installed in front of the gas meters. In the case of single-family buildings, the same rule applies to cables running from 0.5 m in front of the outer wall of the building to beyond the inner face of this wall. The remaining sections can be made of both steel and copper pipes. In the case of the former, threaded connections are allowed in addition to welding. In the case of the latter, brazing is recommended, but here the regulations also allow the use of other connections that comply with the requirements of the Polish Standard regarding gas pipes for buildings.

The acceptance of gas installations takes place after performing the main tightness test of the installation. This test is carried out in three cases: after a new installation, after each reconstruction or renovation and after being out of service for a period longer than half a year. The test is carried out separately before the gas meters and for the rest of the installation.

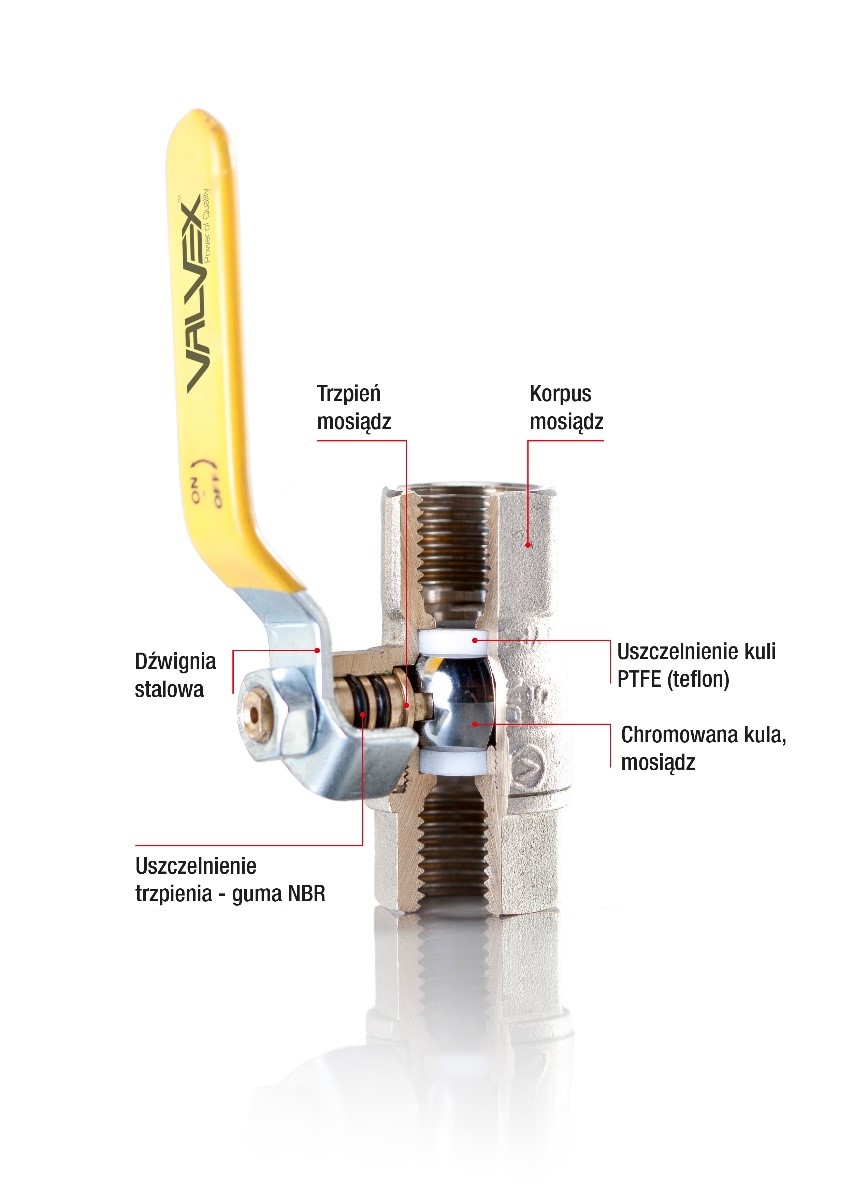

Construction of the Valvex gas ball valve

Check out Valvex ball valves

One would like to write: "Everyone can see which valve it is", but it is not that simple. Gas fittings, including valves , are intricately made objects. The first thing that catches your eye is the handle - a lever made of galvanized steel, covered with yellow plastic. The NBR70 stem seal consists of: a double O-ring made of NBR70 (KGN); PTFE and O-ring made of NBR70 (KGS, KGMS). High-quality CW617N brass was used to build the durable body. The brass ball is finished with chrome and polished. In addition to all this, there is also a PTFE ball seal . All elements are made of the highest quality materials and together they create a gas ball valve that meets the requirements of European standards.

Which gas ball valve should you choose? Types available

Among the ball valves available on the market, we recommend two types in particular. These are:

ORION valves stand out from the competition thanks to, among other things, their extended operating temperature range (class T3). They work flawlessly both in 40-degree frost and 60-degree heat. In addition, they can be subjected to pressure conditions up to 20 bar (MOP 5-20). ORION valves are available in two variants : with an ergonomic aluminum butterfly or with a reinforced steel lever. Orion valves meet all requirements for gas valves in terms of fire safety

An innovation among gas valves available on the market is the 4TECH valve. The most important advantages of this valve include a patented sealing system that makes the valve self-sealing in the event of a fire . Copper rings, used in addition to Teflon seals, provide additional sealing of the valve ball. This is unique and also required by law to provide protection against fire. Instead of the Teflon and rubber seals melted as a result of the rising temperature, copper rings remain, which seal the valve due to the thermal expansion of the material. This stops gas leakage and reduces the risk of explosion.

The valve itself is not everything - what else to buy?

When choosing a valve, it is worth selecting additional elements, such as V-GAS brass filters. These filters are used in installations for the initial purification of the energy carrier gas. They have the same resistance to high and low temperatures as the ORION valves described above. Moreover, the operation of V-GAS filters is based on the use of an appropriate cartridge. Thanks to the filter meshes (700 per 1 cm²), it is impossible for dirt to enter the installation (cleaning accuracy: ~0.2 mm).

Safety is the basis. Therefore, before starting to install gas installations, let's carefully read all the formalities we need to complete. An approved design by a designer with appropriate permissions is only an introduction to further assembly. Connecting gas requires specific permits and precision at a later stage of work. It is also worth investing in a proper ball valve . ORION or 4TECH models will ensure safety even in extreme conditions and in case of crisis situations.