Electrical installations that are particularly exposed to harmful external factors should be additionally protected. For this purpose, protective pipes made of various materials are used. The selection of the appropriate variant depends primarily on the location and parameters of the cables. The issue of the diameter of the cables also requires special attention. What should you remember?

From this article you will learn:

- what types of cable protection pipes are there,

- what should be the diameter of the casing pipe,

- what protective pipes can be found in the Onninen offer.

Cable protection pipes – execution and design

High-density polyethylene (HDPE) is most often used to produce protective pipes . It is used primarily due to its impressive durability and wide operating temperature range. It is also resistant to destructive atmospheric factors and most chemical compounds. This type of protective pipes is used to protect: • low and medium voltage power cables, • copper and fiber optic telecommunications cables, • cable television networks. HDPE is perfect for demanding environments where cables are subject to significant external loads. For this reason, protective pipes made of this material are used, among others, in all types of soils - including irrigated and chemically aggressive ones. The exceptional flexibility of polyethylene effectively relieves stresses resulting from ground subsidence.

HDPE protective pipes can also be used to protect cables laid outdoors. Sometimes other materials are also used for this purpose. The key parameter in this case is resistance to UV radiation. This type of cables are produced in black and contain substances that protect against ultraviolet light, which accelerates the wear of materials. When installing the installation, frequent temperature changes should also be taken into account, causing changes in the length of the casing pipes in this environment.

HDPE protective pipes can also be used to protect cables laid outdoors. Sometimes other materials are also used for this purpose. The key parameter in this case is resistance to UV radiation. This type of cables are produced in black and contain substances that protect against ultraviolet light, which accelerates the wear of materials. When installing the installation, frequent temperature changes should also be taken into account, causing changes in the length of the casing pipes in this environment.

In addition to installation pipes for running cables in the ground and in the open air, cable covers for building installations are also available on the market. They are made of polypropylene (PP). It is a material characterized by mechanical strength and significant stiffness, which decreases with increasing temperature. Even better parameters are characterized by polyamide (PA6), which is resistant to abrasion and effectively dampens vibrations. For this reason, it is used in extremely difficult operating conditions.

You will also find galvanized steel casing pipes in stores. They are used to protect electrical cables running next to hydraulic and pneumatic lines, as well as in floor installations in industrial premises. It is also worth mentioning:

- steel casing pipes with a polyvinyl chloride (PVC) or polyamide (PA6) jacket - protecting against acids, alkalis and other aggressive chemicals,

- casing pipes made of non-flammable, self-extinguishing halogen-free materials - used in facilities with increased fire risk.

Check cable protection pipes from Q-Systems

Installation pipe systems – what to pay attention to during installation?

When choosing casing pipes for various electrical installations, it is necessary to take into account certain nuances regarding their design and even appearance:

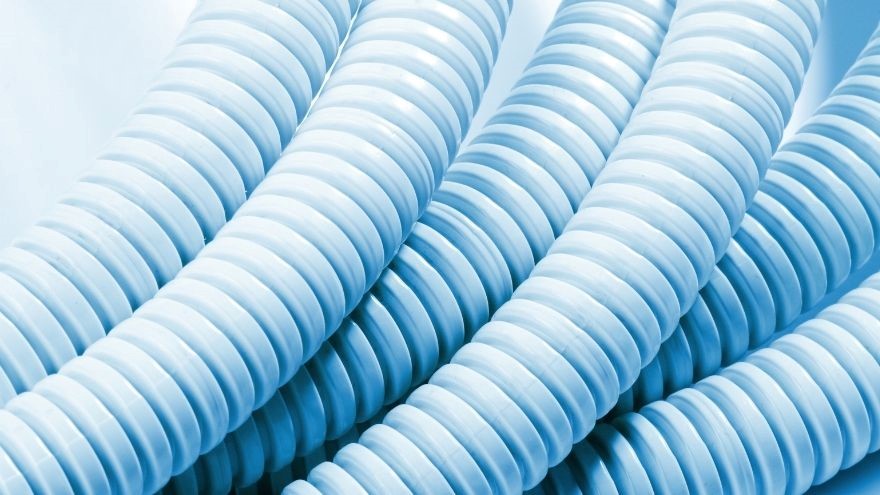

- Double-walled conduits are used to protect low and medium voltage cables. They can have corrugated or smooth surfaces. This solution guarantees lightness and flexibility of the installation, and at the same time a high level of mechanical strength.

- During assembly, individual sections of protective pipes are connected with unions or sockets made of the same material. Cable pulling is possible thanks to the smooth internal surfaces of the cables or pilot lines.

- In the case of cable pipelines laid in the ground, the color of the pipes is very important. Blue characterizes wires protecting low-voltage cables, and red - medium-voltage cables.

Selection of the diameter of cable protection pipes – what should you remember?

In order to create a complete, efficient electrical cable protection system, various parameters of the protected cables and the specificity of the environment in which they work must be taken into account. We have already written a lot about the installation location in the first part of the article, so let's now consider how the properties of the cable itself influence the selection of covers. The key factors include the type of electric cable and its diameter.

In order to create a complete, efficient electrical cable protection system, various parameters of the protected cables and the specificity of the environment in which they work must be taken into account. We have already written a lot about the installation location in the first part of the article, so let's now consider how the properties of the cable itself influence the selection of covers. The key factors include the type of electric cable and its diameter.

These parameters will primarily determine the diameter of the cover and the thickness of its wall. Remember that the inner diameter of the conduit should be 1.5 times the outer diameter of the power cable and 2 times the outer diameter of the fiber optic cable.

The type of cables used in the electrical installation will also affect the required IP tightness level of the sheathed cables. Detailed provisions regarding this parameter can be found in the EN 60529 standard.

Cable protection pipes in the Onninen offer

If you are working on an electrical installation that requires additional protection, our online wholesaler offers high-quality Q-SYSTEMS protective pipes. It is a manufacturer that supplies the market with complete pipe systems and cable protection accessories. It is impossible to deny his experience and attention to the smallest details.

Exchange benefits in the new OnnTop loyalty platform!

Q-SYSTEMS protective pipes are created by a team of professionals committed to continuous improvement of their products. The production process is supported by the latest technology, which translates into a guarantee of reliability while maintaining competitive prices.

Numerous Q-SYSTEMS products are available in the Onninen offer. You will find, among others:

- Red corrugated pipes in coils - these are wires with a diameter of 160 mm used to cover medium voltage cables laid in the ground. They are made of polyethylene, making them perfect for demanding environmental conditions. They can be easily bent, which allows you to conveniently adapt them to the shape of the excavation. Despite their high resistance, the pipes retain low weight and are suitable for manual assembly.

- Blue cable protection pipes - corrugated cables used to protect low-voltage cables laid in the ground. They have a smaller diameter of 40 mm. Moreover, due to the use of polyethylene in their production, they closely resemble the variant of red corrugated pipes described above.

- Smooth-wall optical fiber tubes - cables with a diameter of 32 mm, used to cover optical and copper telecommunications cables. Internal grooves and a slip layer allow for easy installation of long sections of the network, both pneumatically and mechanically. They are available in variants with longitudinal stripes in various colors, consistent with their intended use.

- Sealing inserts – elements used to improve installation efficiency, available in various diameter ranges.

- Connectors for fiber optic pipes - accessories that allow for quick and convenient connection of cables of different diameters.

As you can see, thanks to the Q-SYSTEMS brand range, available at the Onninen electrical wholesaler , you can easily design and implement a complete electric cable protection system!

Do you have questions about the industry? Join the Świat Instalacji group!