He who cleans, warms! A heating installation based on a heat pump , even the most modern and ecological, will not operate efficiently in the long run without an appropriate system for capturing and removing contaminants from the water. What solutions should be used? Read below!

From this article you will learn:

- what are the methods of purifying heating water,

- Is the filter alone enough?

- how to support its operation.

Potential threats occurring in installations

Caleffi is known on international markets and in Poland as a supplier of high-quality elements intended to secure sanitary installations. Several decades of cooperation with leading suppliers of heat sources position us as an expert in the field of heat source protection. Our unique solution from the 108 series, protecting monoblock air heat pumps, has become an undoubted sales success on the Polish market.

This time, however, we will discuss the issue of protecting heat pumps against another threat that affects virtually every installation, i.e. against contamination. At the very beginning, let's answer the question: What forms of pollution may appear in a working central heating installation? These will include:

This time, however, we will discuss the issue of protecting heat pumps against another threat that affects virtually every installation, i.e. against contamination. At the very beginning, let's answer the question: What forms of pollution may appear in a working central heating installation? These will include:

- deposits of mineral origin (so-called scale);

- suspended particles (sand, metal particles, foreign bodies) coming from the water supply network or entering the installation during its installation or maintenance (welding residues, hemp tow, grease);

- products of oxygen corrosion of materials used to make the installation;

- sludge, which is the result of a combination of oxides of oils used in the production of elements such as radiators and mineral deposits.

All the above-mentioned pollutants can significantly reduce the efficiency of the system and its service life, which directly translates into heating costs! Therefore, it is worth choosing appropriate solutions at the very beginning of your adventure with a heat pump that will best protect both the new and modernized installation.

Check out the offer of Caleffi filter products

So where to start choosing the right device?

The market is full of various types of devices. How can you choose the right one in such a rush, when most of them look the same at first glance, and each manufacturer ensures that their product is the only one?

And this is where Caleffi comes in with a wealth of accumulated knowledge and ready-made answers, because we have been dealing with this issue for several dozen years! Let's start from the beginning and from the most basic issue, which is the removal of "coarse contaminants". For this purpose, the simplest solution is a mesh filter. However, it should be noted that this cannot be the only way to eliminate contaminants, and filters alone cannot protect the system against the most dangerous contaminants!

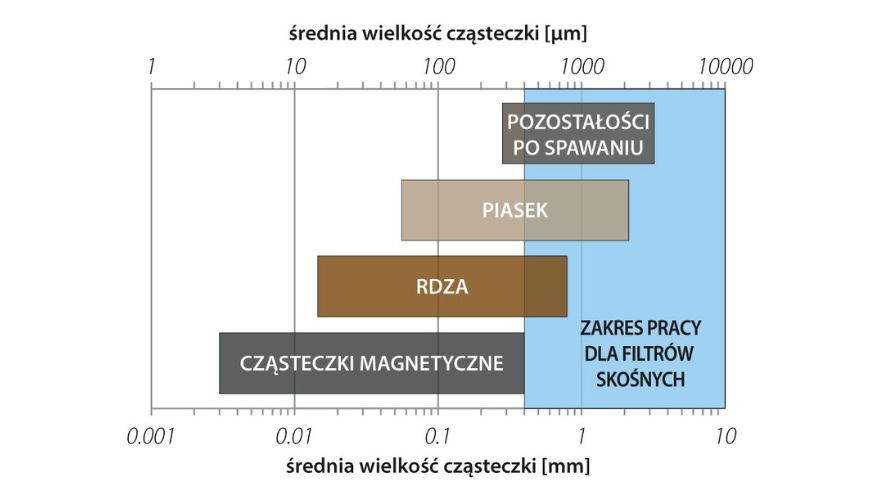

The principle of operation of these basic elements is based on the mechanical separation of impurities, which are retained in the filter cartridge. The basic parameter characterizing the filter is the mesh diameter (or filtration capacity). This size defines the size of the pollutant particles that can be captured by the filter. For example, using a filter with a mesh diameter of 0.4 mm (400 μm) can remove contaminants with a diameter greater than or equal to this value.

Filters are therefore unable to effectively remove sand, rust and magnetic particles from installation water. The latter will not be retained by the filters not only due to their size, but also in the absence of an additional magnetic element.

Attention should also be paid to the fact that accumulating impurities increase the pressure losses generated by the filter. The pressure loss in a 70% contaminated filter increases approximately four times compared to a clean device. That is why it is extremely important to periodically check how dirty the filter is!

It should be noted, however, that the filters, despite their shortcomings, retain contaminants already during the first use, which is their undeniable advantage. Unfortunately, efficiency limitations currently preclude their use in installations as the only protection, because the greatest threat comes from fine contaminants (below 200 μm), including ferromagnetic contaminants.

To ensure the highest efficiency of dirt removal in a system with an installed mesh filter, a dirt separator with a magnetic element should be used. We will describe this solution in detail at the very end of this article, but now let's deal with filters with a magnetic cartridge. This solution was created to protect the system against "thickers

To ensure the highest efficiency of dirt removal in a system with an installed mesh filter, a dirt separator with a magnetic element should be used. We will describe this solution in detail at the very end of this article, but now let's deal with filters with a magnetic cartridge. This solution was created to protect the system against "thickers

pollutants and ferromagnetic particles. Due to the use of a filter mesh insert inside, such a device shares all the disadvantages , but also all the advantages, of the oblique filter described earlier. The additional magnetic insert is simply intended to remove small ferromagnetic impurities. An example of this type of solution is the Dirtmag Mini filter.

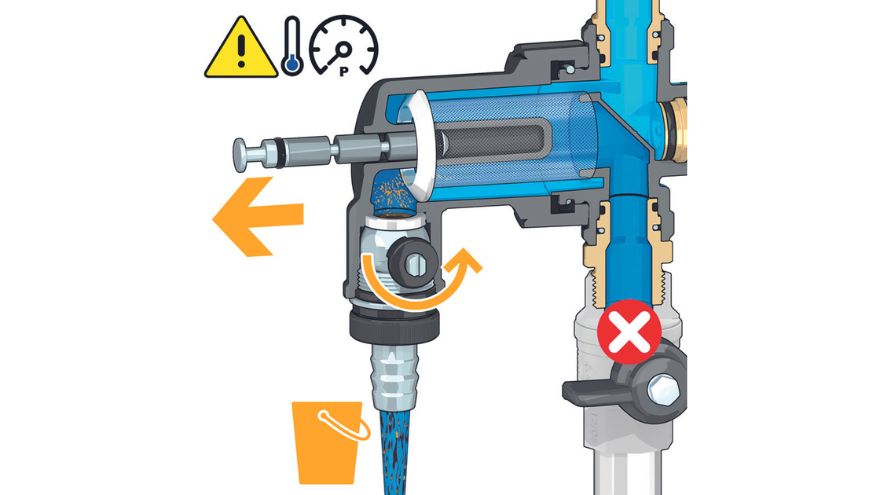

Unlike traditional inclined filters and similar solutions offered on the market, in this case the process of cleaning the filter cartridge has been simplified. The special design allows for rinsing out impurities accumulated in the internal cartridge by forcing reverse flow. This eliminates the need to disassemble the device body during standard cleaning.

Thanks to the use of a high-power magnetic insert (13,000 gauss), all ferromagnetic impurities are eliminated from the heating medium, which constitute a potential threat to most components in installations. Unfortunately, even this solution, combined with a filter cartridge, does not eliminate all contaminants.

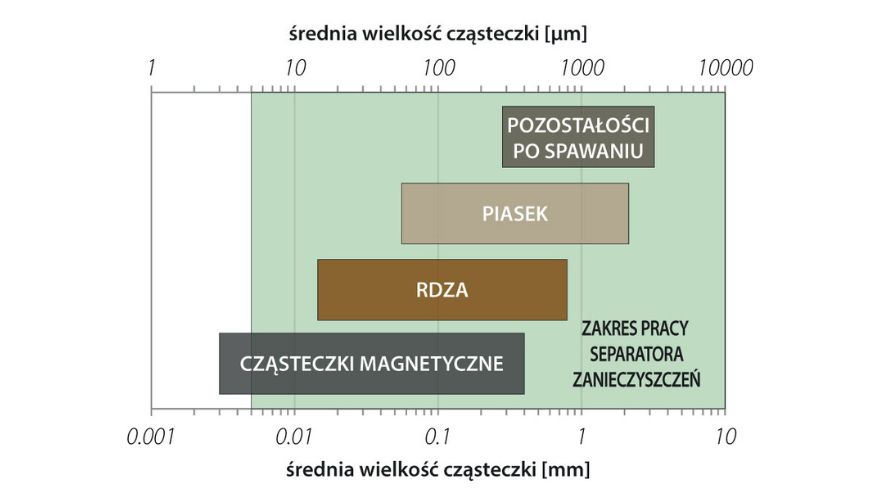

This is where pollution separators come into play, i.e. devices with the highest efficiency in eliminating pollutants from the solutions currently available on the market. By using the phenomenon of precipitation under the influence of gravity, it is possible to separate particles with a diameter of up to 0.005 mm (5 μm), which is many times smaller than in the case of traditional filtration.

Check out the offer of Caleffi inclined filters

The gravitational separation process itself is based on the combination of several physical phenomena, such as:

- reducing the speed of the medium - favors the gravitational fall of contaminants in the collection chamber,

- internal element - causes impurities to be precipitated from the flowing medium, which fall into the chamber located at the bottom of the device.

Separation occurs continuously, but complete removal of contaminants requires several dozen installation cycles. For this reason, mesh filters should be used to remove "coarse contaminants" during the startup phase. However, separators have a huge advantage over mesh filters, which is why they cannot be missing in the medium purification system in the heating installation.

A unique feature of the separators is the collection of impurities in the chamber located at the bottom of the device and on the magnetic elements. This solution means that the hydraulic characteristics will not change significantly as their number increases, and to put it simply, the accumulated impurities will not cause an increase in flow resistance, as is the case with filters .

Another characteristic feature of separators is the method of removing accumulated contaminants. The process is carried out using a drain valve located in the collection chamber. The cleaning procedure of the device does not require disassembling it , it only involves opening the drain valve. Depending on the technical solution of the separator, it can be carried out even while the installation is running.

Another characteristic feature of separators is the method of removing accumulated contaminants. The process is carried out using a drain valve located in the collection chamber. The cleaning procedure of the device does not require disassembling it , it only involves opening the drain valve. Depending on the technical solution of the separator, it can be carried out even while the installation is running.

Dirt separators have very low flow resistance, which translates into the consumption of electricity to power the circulation pump, and thus affects the costs incurred by the user .

The dirt separators offered by Caleffi Hydronic Solutions are a series of Dirtmag devices , in the family of which we can distinguish several technical solutions:

Dirtmag series 5463 - brass version

Characteristics:

- wide range of available diameters;

- high values of recommended flows - high flexibility of operated heat pump systems;

- high efficiency of removing impurities (up to 5 μm);

- installation on horizontal ducts;

- high efficiency of removing ferromagnetic particles;

- possibility of installing an automatic air vent;

- easy to clean via drain valve;

- possibility of dosing chemicals through the separator chamber;

- insulation adapted to work also in cooling installations.

Dirtmag series 5453 - version made of technopolymer

Characteristics:

- recommended flows adapted to typical systems equipped with heat pumps;

- high efficiency of removing impurities (up to 5 μm);

- installation on horizontal and vertical ducts;

- high efficiency of removing ferromagnetic particles;

- manual air vent;

- easy to clean via drain valve;

- possibility of dosing chemicals through the separator chamber;

- insulation adapted to work also in cooling installations;

- shut-off valves.

DirtmagPro series 5457 - version made of technopolymer with a double magnetic insert

Characteristics:

- high values of recommended flows - high flexibility of supported heat pump systems;

- high efficiency of removing impurities (up to 5 μm);

- installation on horizontal and vertical ducts;

- very high efficiency of removing ferromagnetic particles already during the first start-up, due to the use of a double magnet system - especially recommended for modernized installations;

- manual air vent;

- easy to clean via drain valve;

- possibility of dosing chemicals through the separator chamber;

- insulation adapted to work also in cooling installations.

It is worth noting that currently there is an abundance of devices on the market that are sometimes exaggeratedly called separators, and after analyzing the technical solutions, they turn out to be a filter with a magnetic cartridge. To obtain the highest level of dirt removal efficiency, we recommend that you carefully look at the description and structure of the device before purchasing it.

To sum up, the best solution to protect a system equipped with a heat pump is to use both an inclined filter and a dirt separator. This tandem guarantees long and failure-free operation of the device itself, achieving optimal system efficiency and reducing heating costs. He who cleans, warms!