Pentair Corporation under the Starite brand (formerly Nocchi) presents a series of submersible sewage pumps made of AISI 304 steel. A wide selection allows you to choose the right pump exactly according to your needs. Nocchi solutions differ not only in terms of parameters, but also in the size of the free passage, voltage 230 and 400V, versions with or without an automatic switch. A common feature is the "vortex" impeller.

Application of Pentair sewage pump:

- due to the large free passage they can be used for fecal sewage

- can be used as portable or stationary solutions ( sewage pumping stations in systems with 1 or 2 pumps)

Check out Pentair sewage pumps at the Onninen wholesaler

Basic advantages of a sewage pump:

Basic advantages of a sewage pump:

- large free passage – up to 50 mm;

- impeller and pump housing made of AISI 304 steel;

- so-called Somocleaning rotor;

- very strong mechanical seal; very high operating parameters – up to 18 m lift and 800 l/min.

What's new in the priox pump series

What's new in the priox pump series

- priox 50 380/8 m aut (hmax = 9 m, qmax = 380 l/min, free passage 50 mm)

- priox 50 500/11 m aut (hmax = 11 m, qmax = 500 l/min, free passage 50 mm)

+ 230v versions without automatic switch and 400v

Submersible pumps for dirty water U3KS, U5KS, U6KS, brand JUNG are manufactured in Steinhagen - a German factory with almost 90 years of tradition. They can be used for both stationary and portable applications. The pumps pump rainwater, contaminated water e.g. from flooded basements, from domestic dishwashers and washing machines (with the cooking process), with the exception of toilets and urinal installations.

The individual models differ primarily in their operating parameters:

| Model | Efficiency Qmax | Lifting H max |

| U3KS | 6.5 m3/h | 7 m |

| U5KS | 12 m3/h | 8m |

| U6K ES | 16 m3/h | 10m |

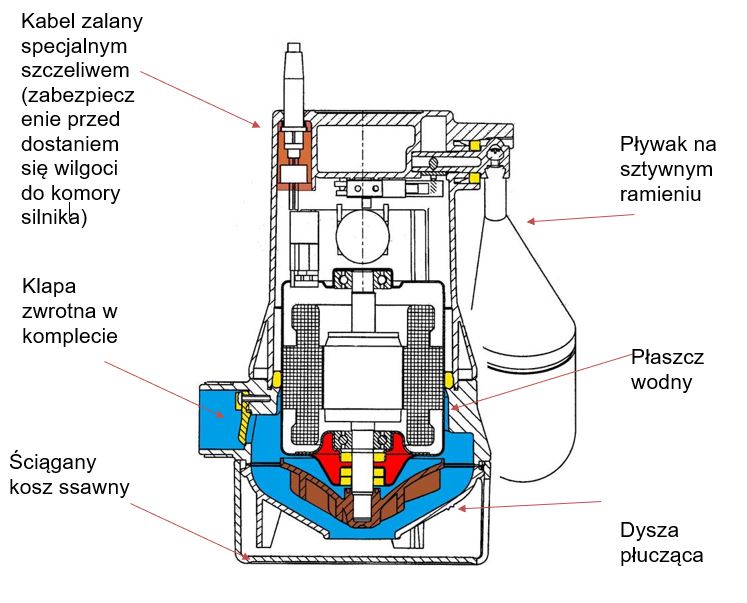

Pump cross-section (model U3KS)

It stands out from the crowd of similar pumps due to the following aspects:

- Float switch on a rigid arm – reliability and constant switching height

- Cable filled with a special sealant - a substance that prevents moisture from entering the engine compartment

- Rinsing system – prevents the pump from becoming clogged with solids (leaves, etc.)

- Removable suction basket

- Dry running permitted - triple shaft seal with sealing rings and intermediate oil chamber

- Shallow pumping system – after removing the basket and blocking the float, the pump sucks water to a level of 5 mm.

It is also worth mentioning that sewage pumps have a very wide range of additional equipment. The basic items in this area include:

- special float for low levels,

- special float for narrow shafts,

- check valves,

- control systems with floats for single and dual pump systems,

- GR32 coupling system – for stationary applications.