More and more people are choosing underfloor heating. It must be admitted that this solution has many advantages. First of all, it ensures comfort and convenience of use, and the heat rising from the bottom warms the entire room evenly. Today we will show you how to perform the installation step by step.

Check out KAN-therm products for underfloor heating at the Onninen wholesaler

How to install a floorboard yourself?

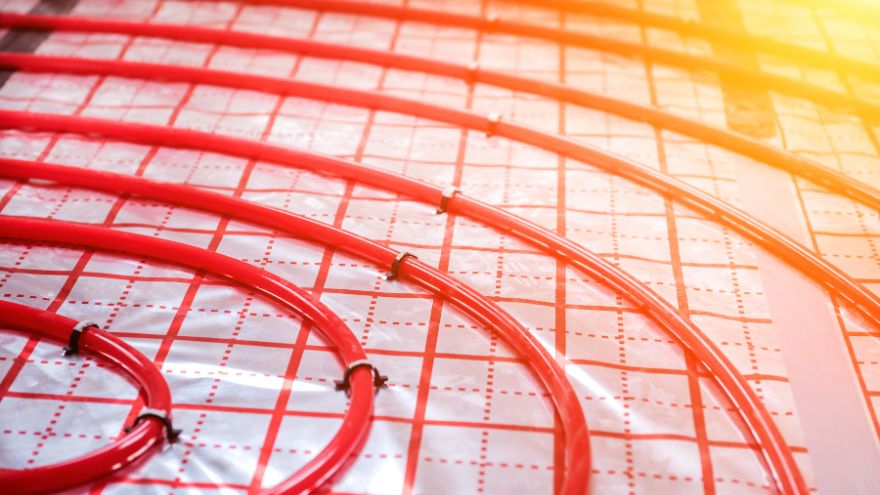

Underfloor heating is a really good alternative to traditional wall radiators. Please remember that proper installation is important for it to work properly. First, you need to choose the right design. The most effective solutions should be considered. You need to take into account the type of flooring here  also the arrangement of permanent design elements. Already at the design stage, the question should be answered about which pipes are worth choosing. You can choose copper pipes, which are durable and resistant to high temperatures, or choose those made of plastic, e.g. polypropylene, which are also durable and flexible. Copper pipes are definitely more expensive. Begin laying each pipe by attaching one end to the supply manifold. In the next stage, the pipes are gradually unrolled and immediately attached to the ground with special holders. It is necessary to maintain the established distances between adjacent sections. The standard spacing is from 10 to 20 cm. You still need to use the optimal pipe length. Underfloor heating creates a loop of individual pipe sections, but this loop should not be longer than 150 m, otherwise it may cause high hydraulic resistance. Pipes are always routed in a specific way, forming a spiral, so that in subsequent rows there is an alternating supply and return section. Manifolds are always installed in pairs, i.e. supply and return. In the first one, water flows from the boiler room, while in the second one it is discharged back to the boiler room.

also the arrangement of permanent design elements. Already at the design stage, the question should be answered about which pipes are worth choosing. You can choose copper pipes, which are durable and resistant to high temperatures, or choose those made of plastic, e.g. polypropylene, which are also durable and flexible. Copper pipes are definitely more expensive. Begin laying each pipe by attaching one end to the supply manifold. In the next stage, the pipes are gradually unrolled and immediately attached to the ground with special holders. It is necessary to maintain the established distances between adjacent sections. The standard spacing is from 10 to 20 cm. You still need to use the optimal pipe length. Underfloor heating creates a loop of individual pipe sections, but this loop should not be longer than 150 m, otherwise it may cause high hydraulic resistance. Pipes are always routed in a specific way, forming a spiral, so that in subsequent rows there is an alternating supply and return section. Manifolds are always installed in pairs, i.e. supply and return. In the first one, water flows from the boiler room, while in the second one it is discharged back to the boiler room.

What do you need for underfloor heating?

When preparing underfloor heating, you must remember how important the appropriate tools and accessories are. The first one is the floor distributor . Here, you need to choose a model depending on your circuit needs. Another important element is the regulation set and the insulating foil for the floor . Here we recommend a product made of polyethylene and polypropylene foil. It is durable and perfectly protects the cement mortar against moisture. During installation, it also reflects heat rays, thus preventing heat loss. A compression fitting that is selected according to the size of the valves is also useful. You should also choose underfloor heating pipes or mounting rails. For even greater convenience of use, a thermoelectric head is used, and clips are useful for mounting.

Underfloor heating - step by step installation

Installing underfloor heating requires precision. It takes place in several steps.

- Step one: preparation of the substrate and heating insulation

Before we proceed to the full heating installation, we need to prepare the subfloor. They must be thoroughly cleaned, leveled and dried, otherwise mold and fungus may appear after pouring the screed. They are not only harmful, but will also make the underfloor heating work inefficiently.

- Step two: laying the foil

Once we have thoroughly cleaned the surface, we can proceed to installing the moisture-proof foil insulation. After attaching it, we lay the polystyrene and only then another layer of foil with an anchor mesh to attach the pipes.

- Step three: installation of heating circuits

This is one of the most important elements of the underfloor heating installation. One circuit should be a maximum of 100 meters. If it is longer, the heating may not work properly. We attach the pipes to the floor using special clips, and connect the pipe ends to the water distributor.

- Step four: performing a pressure test

After attaching the pipes, we perform a leak test, which means we inject water under pressure into the pipes.

- Step five: making peripheral expansion joints

Place foam tape around the perimeter of the room. It is important to remember that the expansion joints are located under the power cables, not above the loop.

- Step six: pouring the underfloor heating system with screed

At the very end, we perform a concrete screed. Remember that for about 3 weeks after pouring the screed, the room should have a moderate temperature and low air humidity.

KAN products are recommended for underfloor heating

It is worth choosing a product such as the PERT/AL/PERT 16x2 pipe . It is made of polyethylene with increased thermal resistance. Additionally, it has an aluminum jacket that is butt-welded. It is resistant not only to high temperatures, but also to loads. A good choice will also be the PERTAL ultraPRESS pipe - 40x3.5. It is a mandatory part of underfloor heating. It has high thermal resistance and ensures maximum tightness. You can also choose a product such as a multi-layer PE-RT/AL/PE-RT pipe. It is also necessary when creating underfloor heating and ensures effective operation of the installation. It is dedicated to both hot and cold water installations. The product is dedicated to underfloor heating with an operating pressure of up to 10 bar. Each of these products will meet the expectations of the most demanding customers.

Check out KAN-therm products for underfloor heating at the Onninen wholesaler