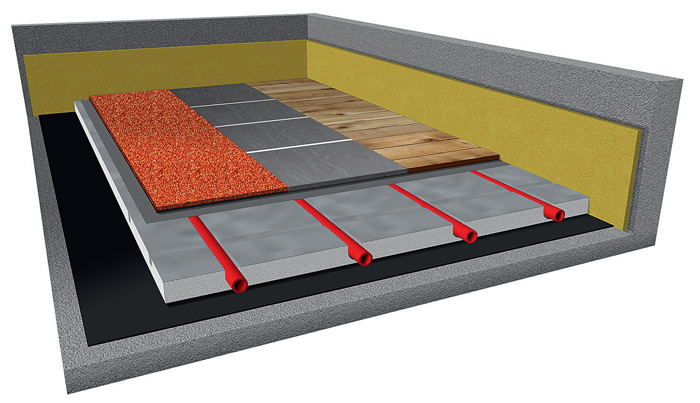

Underfloor heating is currently a very advanced solution in heating technology. It requires special technical conditions that must be implemented at the architectural design stage, and for proper work to meet the investor's requirements - accurate thermal and hydraulic calculations and automatic control.

Underfloor heating is currently a very advanced solution in heating technology. It requires special technical conditions that must be implemented at the architectural design stage, and for proper work to meet the investor's requirements - accurate thermal and hydraulic calculations and automatic control.

Energy savings, high thermal comfort, aesthetics - these are just a few advantages of surface heating. Among the heating solutions proposed by TiA System, everyone will find something suitable for themselves. Importantly, modern solutions allow you to use every surface of the room. Currently, we can provide underfloor, wall and even ceiling heating as part of surface heating , intended for new, modernized or historic buildings, which can be used both in single-family buildings and in large spaces.

Check out the TIA brand area in Onninen now

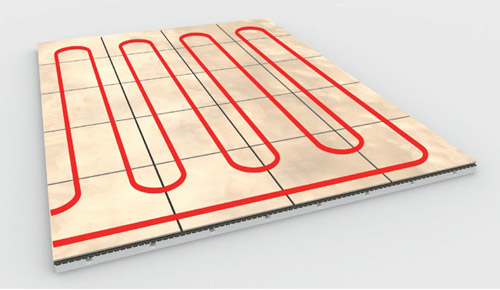

Among all types of surface heating, the most popular solution is still classic underfloor heating. The increased temperature of the floor means warmth for your feet, which are sensitive to cold, and at the same time lowers the temperature near your head. For efficient operation of such heating, a lower temperature of the heating medium is required than in the case of a convection system. Underfloor heating is a guarantee of comfort and greater hygiene, energy saving and aesthetics in one.

Among all types of surface heating, the most popular solution is still classic underfloor heating. The increased temperature of the floor means warmth for your feet, which are sensitive to cold, and at the same time lowers the temperature near your head. For efficient operation of such heating, a lower temperature of the heating medium is required than in the case of a convection system. Underfloor heating is a guarantee of comfort and greater hygiene, energy saving and aesthetics in one.

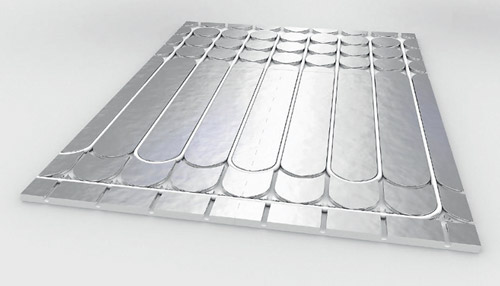

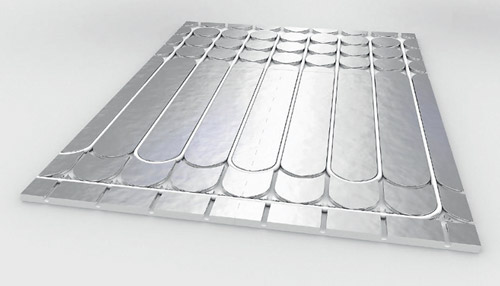

However, what should we do if we want to enjoy underfloor heating on the upper floors of a frame building, or in an existing apartment, or in a newly constructed building where the designer has not provided space for traditional underfloor heating? We also have a technical solution for such a case - the Standard Alu EPS 300 System .

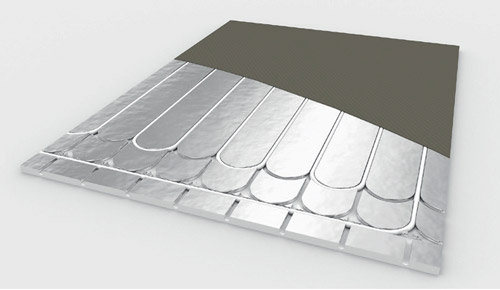

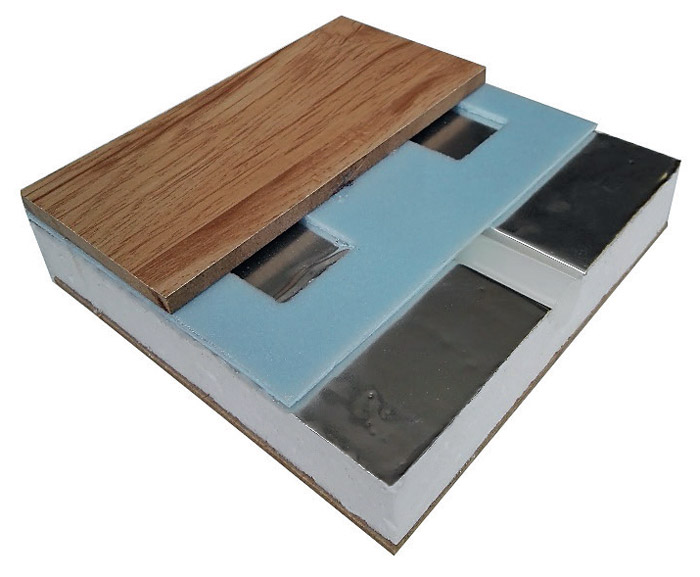

The Standard Alu EPS 300 system is a dry underfloor heating system that, with a low installation height, ensures exceptional substrate stability and at the same time excellent thermal efficiency. Prefabricated elements made of EPS 300 are coated on the outside with a layer of aluminum, which acts as a radiator that conducts heat from the side of the pipe to the entire surface of the system board. This solution guarantees an even temperature of the floor surface, which is important both for comfort and human physiology. Technological channels made in the system boards determine the route of the loops at a spacing of 150 mm and ensure perfect fastening for underfloor heating pipes. The unique pattern allows for any loop arrangement and guarantees the contractor's comfort of work. The production of EPS 300 system boards using injection molds ensures repeatability of dimensions and parameters, which guarantees simple and aesthetic installation and ensures the highest quality of the product.

System boards made of EPS 300, 25 mm high, externally coated with an aluminum layer, are characterized by high parameters, such as compressive strength, which is >- 300 kPa; for the insulating layer of the board, the coefficient λ = 0.035 W/mK ensures optimal thermal insulation parameters for this height of the board.

Check out the TIA brand area in Onninen now

The Standard Alu EPS 300 system, as a dry underfloor heating system, does not require the use of a screed

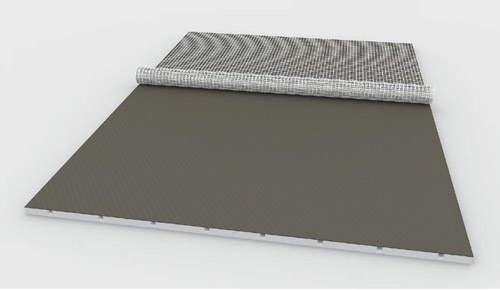

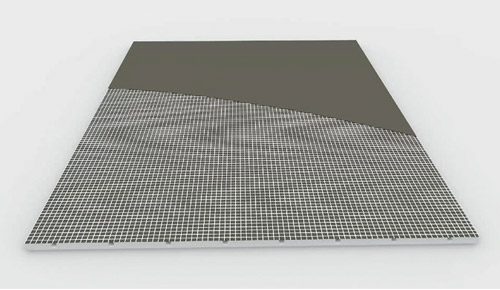

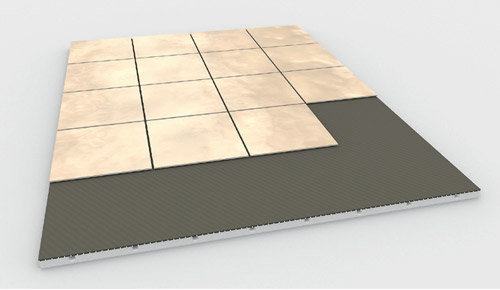

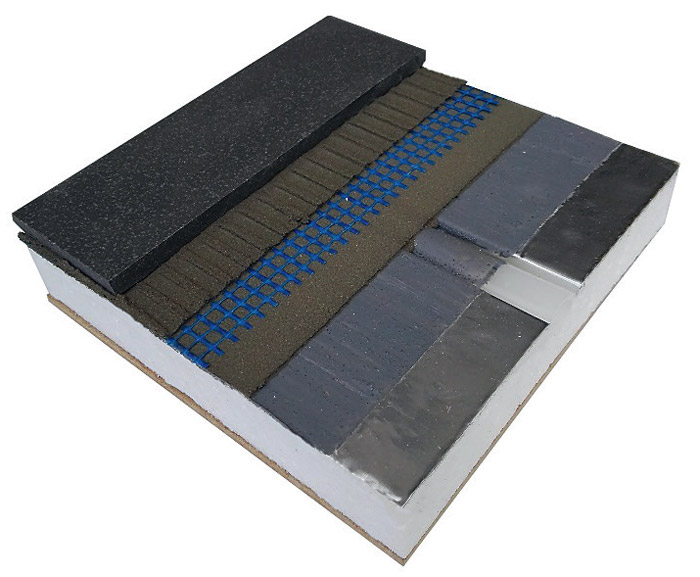

Underfloor heating systems in dry construction do not require a concrete screed. Tiles, panels and carpets are placed directly on the system board. The pipeline and the system board create a flush surface. If underfloor heating is performed in accordance with the art of construction, the EPS 300 class polystyrene used provides sufficient support for any type of floor finishing. The illustrations below show the actual cross-section of heating floors.

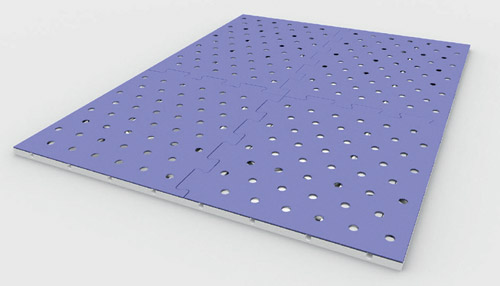

Depending on the requirements related to the target height of the floor, its required load-bearing capacity and the type of finishing (e.g. laminated panels, ceramic tiles, carpet), we offer solutions to stabilize the dry screed. Simply put, we can install carpets and PVC, as well as panels and ceramic and stone tiles on our dry underfloor heating systems... All floor finishes should have the manufacturer's information on the label that they can be used on underfloor heating. Special adhesives and flexible joints should be used for gluing ceramic and stone tiles; the height of the adhesive layer must always be matched to the size of the tile. For floors that are more demanding in terms of durability, screed boards should be used.

The underfloor heating system using System Standard Alu EPS 300 technology is an excellent solution for investments where there are no technical conditions enabling the pouring of a concrete screed weighing several tons. This system is light, low and quick to install. It is used both in renovations and in newly constructed buildings, in wooden and frame construction. In addition, it is characterized by thermal inertia reduced to a minimum - it heats up and cools down faster, which makes it easily subject to smooth automatic control, which was problematic in traditional underfloor heating systems finished with concrete screed.