Manifolds, one of the most popular elements of hydraulic installations, are devices that enable individual power supply to individual water intake points, devices or individual heating sections. Due to the type of installation, they differ not only in material, but above all in construction and functionality. The extensive offer of these devices allows for optimal selection for a specific installation, but may also pose many problems when choosing a specific type. So what should you pay attention to and what should you know when choosing a given product?

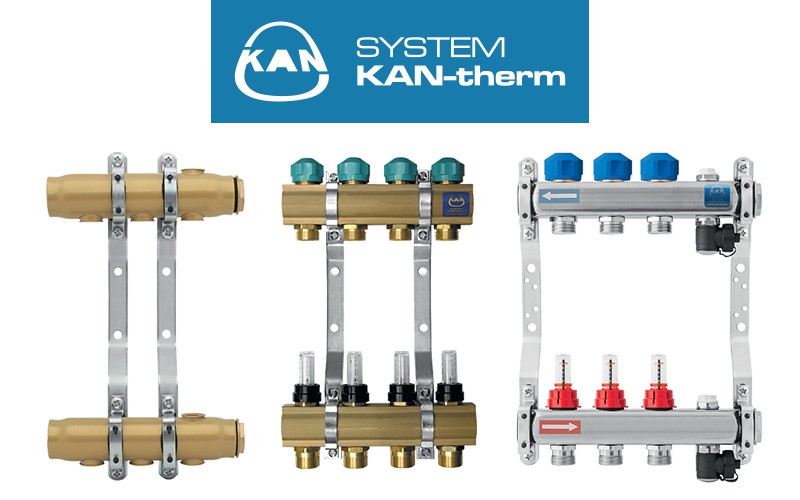

Installing a radiator heating installation in a distributor system is a very popular practice, which is why there are many different types of devices available on the installation market that enable its construction. The KAN-therm System offer includes several complete solutions, differing in material, construction and functionality, which are used to perform such an installation. These include brass and carbon steel manifolds. The group of brass distributors includes structures marked with a series 61, 81, 82 and 74.

See KAN-therm manifolds in the Onninen wholesaler

Manifolds for underfloor heating

The first two distributors, i.e. series 61 and 81, are relatively simple and consist of brass beams (with G3/4" nipples - series 61 or without nipples with 1/2" internal thread - series 81 ) with a profile size of 1". The beams are finished with a 1" internal thread on one side and plugged with a brass plug with its own seal on the other. Both beams are mounted in galvanized steel clamps, equipped with rubber inserts that dampen vibrations and noise from the installation. In both cases, the spacing of holes and nipples is 50 mm. The upper and lower beams, both in the 61 and 81 series manifolds , are additionally equipped with a hole with a 1/2" internal thread in their upper part. This is the place to install the air vent.

Manifold for KAN-therm 74 series underfloor heating

The 74 series manifold has brass beams equipped with shut-off valves. Thanks to them, it is possible to completely cut off the flow through a given heat receiver (e.g. a radiator) and dismantle it freely. The Series 74 manifold requires a drain and vent section to be installed at the end of the beam, so it is not standardly equipped with a blanking plug.

Manifold for KAN-therm series 10 and 20 underfloor heating

Another group, this time of products made of carbon steel, are the 10 and 20 series distributors. Their design is an almost exact copy of the structure of the 61 and 81 series brass distributors. The distributors are covered with a durable paint coating on the outside, protecting the beams against corrosion. Due to the corrosion process, these manifolds should only be used in closed, pressurized heating installations.

Surface heating/cooling installations – floor, wall

Surface heating or cooling installations (floor or wall) are installations in which the distributor is responsible for even distribution of the medium to individual heating or cooling loops. Also in this case, the KAN-therm System offer includes several different designs and types of these devices. Unlike central heating manifolds, the manifold beams for central heating are equipped with control valves or flow meters enabling hydraulic regulation of the entire installation. Thanks to this, the heating or cooling medium will flow equally to all loops, thus ensuring proper operation of the entire OP installation.

In the case of brass versions, we can distinguish as many as four different designs. The 51 and 55A series manifolds only enable hydraulic adjustment of the installation thanks to control valves or flow meters installed on the lower manifold beams. The 71A and 75A series manifolds, apart from the mentioned control valves and flow meters, also have thermostatic valves installed on the upper beams. They enable additional installation of automation elements (electric actuators), thanks to which we can control the operation of the entire OP installation. Each of the above-mentioned distributors has 1" beams equipped with G3/4" nipples (Eurokonus) for connecting the OP loop.

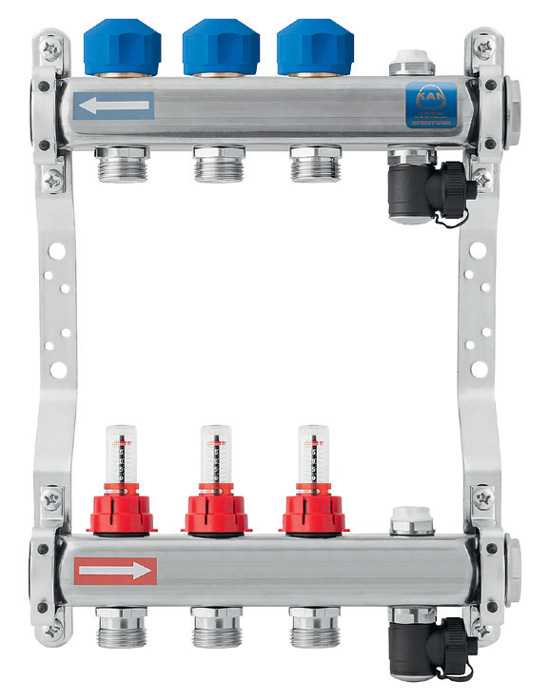

N75A series distributors

New in the KAN-therm System offer are OP manifolds made of stainless steel, marked N75A series. N75A series manifolds are equipped with flow meters and thermostatic valves for installing control automation actuators. This type of manifold also has a built-in drain and vent section - it is installed as an additional heating/cooling circuit. Unlike all brass versions, the N75A series distributor has an increased beam size, which in this version is 11/4". Thanks to this design, the distributor allows for much higher flows, and thus allows for the transfer of much greater power. By using the N75A series manifolds, we can service larger heating or cooling surfaces. See KAN-therm manifolds in the store

New in the KAN-therm System offer are OP manifolds made of stainless steel, marked N75A series. N75A series manifolds are equipped with flow meters and thermostatic valves for installing control automation actuators. This type of manifold also has a built-in drain and vent section - it is installed as an additional heating/cooling circuit. Unlike all brass versions, the N75A series distributor has an increased beam size, which in this version is 11/4". Thanks to this design, the distributor allows for much higher flows, and thus allows for the transfer of much greater power. By using the N75A series manifolds, we can service larger heating or cooling surfaces. See KAN-therm manifolds in the store