Pipe installations - water and heating - are quite sensitive systems whose strength and safety are determined by critical connections. Therefore, fittings responsible for tight and durable connection of pipes are one of the most important elements in all installations. The KAN company, which introduced the KAN-therm UltraLine system, devotes a lot of attention to them. What does it consist of and what are its advantages? Get to know the scope of its applications and find out what this innovative method of connecting pipes is all about!

KAN-therm UltraLine - what is this system and what does it consist of?

KAN-therm UltraLine is a complete installation system consisting of polyethylene, multi-layer pipes, brass and plastic fittings. The pipes are connected to each other by sliding a plastic sleeve over the connector. This method guarantees the reliability of pipe installations without requiring any additional seals.

Polyethylene pipes

In the KAN-therm UltraLine system, polyethylene pipes are available in 2 material variants - PE-RT and PE-X?:

- PE-RT - pipes are made of a special variety of polyethylene with increased resistance to high temperature. The pipes owe their excellent mechanical properties to the unique molecular structure of the material. They are characterized by, among other things, flexibility, which makes them easier to arrange. Thanks to thermal and pressure stability, pipe installations are exceptionally durable.

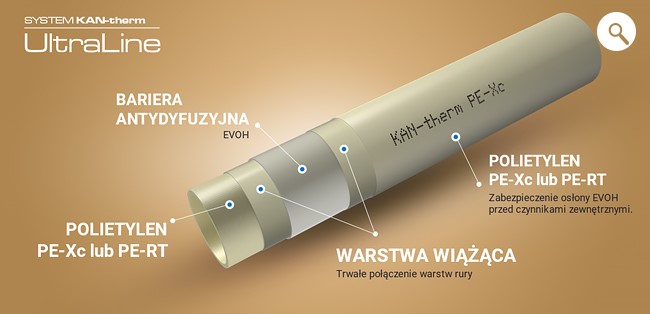

- PE-XC - is an advanced material produced in the process of cross-linking polyethylene with an electron beam. This treatment allows for high resistance to mechanical and thermal loads. Thanks to the EVOH coating that prevents air from entering the installation, these pipes can be used in both water supply and heating systems. This barrier is also used in PE-RT pipes.

Multilayer pipes

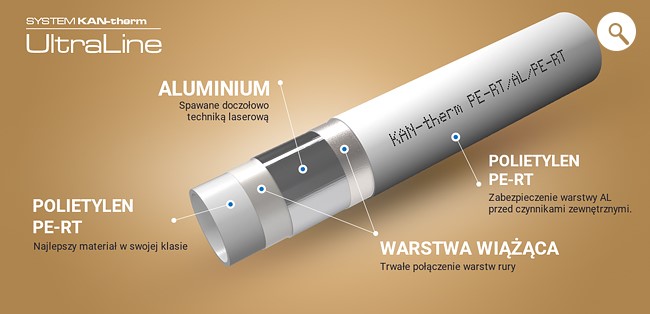

PE-RT/AI/PE-RT pipes have a multi-layer structure, in which the base pipe is made of high-temperature resistant PE-RT polyethylene. The same applies to the outer layer, which protects the installation against mechanical damage. Between the two there is an aluminum coating that prevents air diffusion and at the same time reduces the thermal expansion of the pipes. Their design means that they do not have shape memory, so they can be formed freely.

Brass and PPSU fittings

High-quality clamping fittings play a special role in the KAN-therm Ultraline system. They are made of solid brass or innovative PPSU material and have a sliding sleeve for connecting individual elements of piping systems. The company's product range includes such shapes as:

- tees and elbows,

- brass tees and elbows with threads,

- battery approaches,

- screw fittings,

- collets,

- PPSU or brass connectors,

- twisted and transition connectors.

What is the purpose of the KAN-therm UltraLine system?

The KAN-therm UltraLine system is used to perform internal piping installations:

- water supply (hot and cold water),

- heating,

- as well as special piping installations, such as compressed air.

Pipe connection technique in the KAN-therm UltraLine system

KAN-therm UltraLine pipe installations are connected using the O-ringless clamping method by sliding a plastic sleeve over the connection. As a result, the connection is sealed over the entire joint surface, which guarantees tightness and durability of the installation. Importantly, installation does not require any additional O-ring seals. Let's take a look at how KAN-therm UltraLine pipe installations are connected step by step:

|  |

1. Cut the selected pipe to the required length. Use sharp plastic shears for this purpose and remember to cut perpendicular to the axis. | 2. Put the plastic sleeve on the pipe. |

|  |

3. Equip the manual expander with an expanding head – appropriate for the type of pipe and the appropriate diameter. Insert the expanding head together with the expander until it stops, axially into the pipe end. | 4. Immediately after expanding, insert the connector into the pipe up to the last bead on the fitting's stub. |

|  |

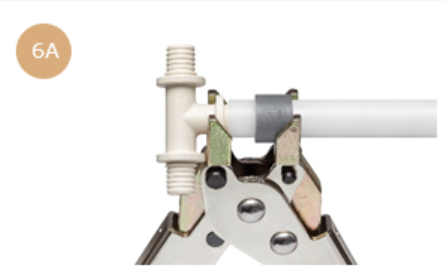

5. Equip the press with special clamping forks. | 6A. Slide on the sleeve using a hand chain press. |

|  |

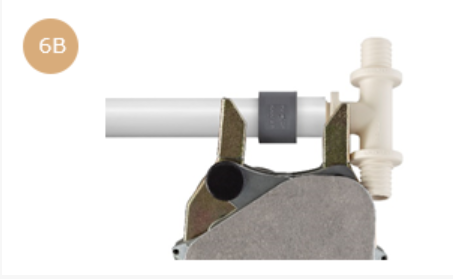

6B. You can slide the sleeve on using electric drives typical for "Press" connections. | 7. When applying the sleeve to the fitting, observe the assembly process. After sliding the sleeve to the fitting flange, stop the sliding process. The connection is ready for pressure testing. |

Why is it worth choosing the KAN-therm UltraLine installation?

The ease and intuitiveness of installation of KAN-therm UltraLine systems deserves special attention. This is undoubtedly the main advantage of this solution, which makes it innovative. The company's many years of experience have allowed it to develop a modern product based on the unprecedented ability to permanently combine various materials within one structure. KAN-therm pipe installations are therefore simple, convenient and quick to install, while guaranteeing high resistance to possible errors.

KAN-therm UltraLine pipe installations - choose O-ring-free connections for professionals!

KAN-therm UltraLine pipe installations integrate various types of pipes and universal fittings and slip-on sleeves. This allows you to create any heating and water supply systems. The solid workmanship of the components and the innovative assembly method guarantee comfort and safety of work, as well as durability, which distinguishes these pipe installations from the products of competing companies. Get to know KAN-therm UltraLine today!