Ball valves are widely used in all piping systems. This is due to their durability and simple, failure-free design. The multitude of applications has resulted in the development of many types of valves for specific applications. Check which valves are used most often, how they work and how you can install them tightly. We will also tell you how to tell whether the ball valve is open or closed.

Check out ball valves at the Onninen wholesaler

How does a ball valve work?

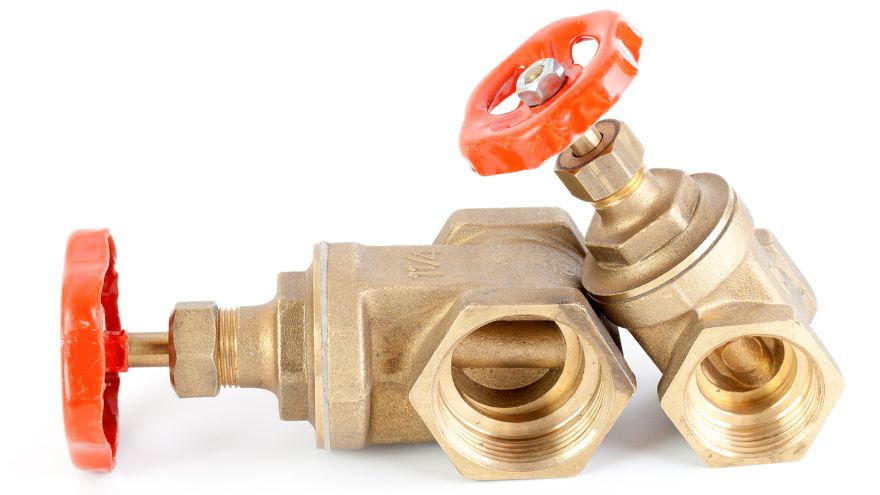

The valve design is not complicated. There is a hollow seat in the valve body. In its center you can find a hollow ball - in one axis it allows the free flow of liquid or gas, but when it is rotated 90°, it completely cuts off any further path. The spherical shape closes under pressure, ensuring maximum tightness. A manual lever is used to rotate the ball, which has movement limits (only allowing rotation by 90°). The lever can also take the shape of a butterfly or a hoop.

What are the types of ball valves?

Ball valve can perform various functions. Therefore, you can find several types of this device, adapted to specific applications. The most popular are:

- Gas ball valve . It is most often made of brass and is used to cut off the gas installation. Due to the flammability of the medium disconnected from the network, such models are characterized by high strength and durability.

- Shut-off valve. Of this type ball valve for water allows you to disconnect the installation from the power supply. Produced in sizes ranging from 1/2 to 3 inches, it can be made of brass, steel or even plastic. Thanks to this, its price is lower.

- The non-return ball valve differs from others in its controllability. This model works completely automatically and its role is to ensure unidirectional liquid flow. When the pressure at the outlet is greater than at the entrance, it causes the ball to move closer and block the flow. However, in the normal state, a small spring pushes the ball out to ensure the flow of the medium.

- The control valve is installed in places where the liquid flow is controlled. It allows you to increase or decrease the amount of water in the installation behind the valve.

- The flanged valve is used in much larger pipelines. It can work under higher pressure, and installation using a flange ensures proper tightness and durability.

- Gas ball valve or water with an additional filter. This type of solution allows you to catch contaminants before the pump or other expensive device. This increases the durability of the entire installation.

Ball valve it is very commonly used in both domestic and industrial installations. The simple design and principle of operation translates into the failure-free nature of such solutions, their high durability and low price.

Which way does the ball valve close?

Many users wonder which way to close ball valve. This question is justified - in most installations it is not visible whether liquid is flowing through the installation or whether the power is cut off. In the case of models with a lever, the principle is quite simple and intuitive - the handle directed along the valve (pipe) means that the liquid flows freely through the valve. However, the perpendicular position cuts off the power supply to the installation. It is possible to place the lever at any angle, which will limit the water flow.

Valves with a knob or butterfly do not have a visible "on" and "off" setting. However, in this case, the principle known from screw connections is used. The valve is tightened clockwise (i.e. closed), and unscrewed counterclockwise. Reaching full closure or opening is signaled by a noticeable, high resistance.

How to seal a ball valve?

Incorrectly installed water ball valve may leak over time. Therefore, it is very important to properly seal the connection between the device and the pipelines. How to do it correctly? It depends on what material we are dealing with. Of course, the entire installation should be carried out uniformly. This means that metal pipelines will be controlled by steel ball valve . What does the seal look like for each type of connection?

- The steel ball valve with thread is sealed with tow or special polymer tapes. In both cases, the seal is wrapped around the thread and then the installation elements are screwed together.

- Plastic ball valve is used at low pressure. Clamp or hot connections are used. Sometimes additional sealing O-rings are used.

- A brass ball valve, often used in gas applications, has PTFE (plastic) seals. In the case of water installations, tow or polymer tapes are used - as in the case of steel models.

In addition to the sealant itself, it is necessary to properly clean the connection and tighten the nut with the appropriate force. A well-made connection is very durable.