Nowadays, when efficient use of energy is becoming a priority, heat recovery units with heat recovery are becoming more and more popular as an effective tool for improving the energy efficiency of buildings. The key element of these advanced ventilation systems are heat exchangers, commonly known as recuperators. What are the types of exchangers used in heat recovery units and how do they differ from each other? You will find out in this article!

Check out recuperators at the Onninen wholesaler

How is the heat recovery system used in single-family houses?

The word " recuperator " has been commonly used in everyday language for many years. What does this term actually mean? A ventilation unit with heat recovery is called a recuperator. Initially, heat recovery was used in large ventilation units with an air capacity of several dozen thousand, then several thousand m3/h. Legal provisions successively reduced this value. According to the current regulation of the Minister of Infrastructure "On the technical conditions to be met by buildings and their location", devices for recovering heat from exhaust air must be used in mechanical ventilation with a capacity of 500 m3/h and more.

The temperature efficiency of the heat recovery device must be at least 50%. However, it is not only the current legal regulations that have contributed to the increased interest in using heat recovery in residential houses over the last few years. Often, the efficiency of the air handling unit at home does not exceed 500 m3/h. People are becoming more and more aware of how important the quality of the air we breathe every day is, which has consequently contributed to the popularization of mechanical ventilation in single-family buildings.

What role does the heat exchanger play in the recuperator?

The recuperator (heat recovery unit) consists of the following elements:

- Heat exchanger

- Supply fan

- Exhaust fan

- Air supply filter

- Exhaust filter

- Sensors

- Electric heater

- Bypass

- Obodowa

We will focus on the most important component located in the heat recovery unit , namely the heat exchanger. It is safe to say that it is the heart of the device. The heat exchanger exchanges heat from the exhaust air (from the rooms) to the supply air (from the outside). Thanks to this, we do not lose all the heat with the removed air (which happens in typical gravity ventilation), and a large part of it can be recovered. This saves energy that would have to be spent on heating the air needed for ventilation.

An important topic accompanying the heat recovery process is moisture recovery, or the lack thereof. The issue of the air humidity level in a room often does not have a high priority when choosing the appropriate device. Air humidity determines many aspects of life and seems to be one of the key elements influencing the comfort of everyday life. Air humidity directly affects our well-being, health problems, the development of fungi and bacteria, the transmission of viruses and the durability of building materials. Therefore, the types of exchangers discussed in detail below will also be described from this aspect.

Division and types of heat exchangers used in heat recovery units

In air handling units with heat recovery, heat exchangers occupy a central place, playing a key role in the effective functioning of the system. They are responsible for transferring heat from the exhaust air to the supply air, which contributes to minimizing energy losses and increasing the efficiency of the entire ventilation process. There are many types of heat exchangers used in heat recovery air handling units, each with unique features and applications. What makes them stand out?

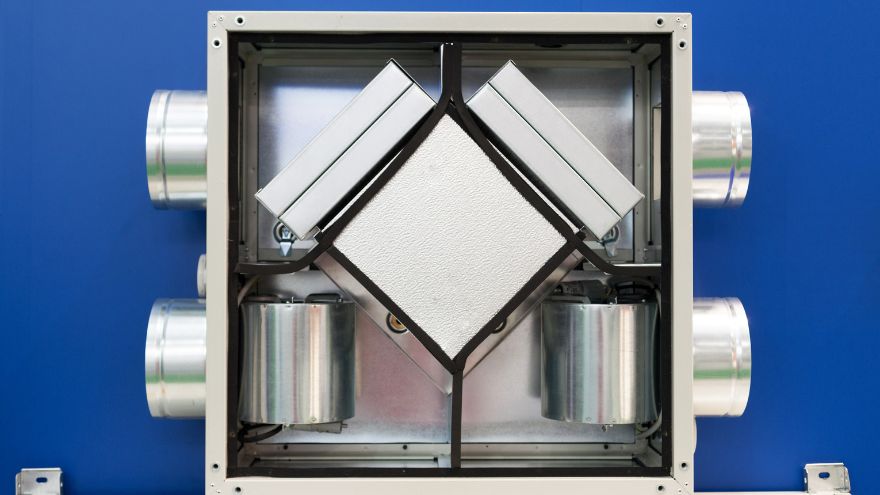

Plate heat exchangers

Plate exchangers are constructed of thin plates made of steel, aluminum, plastic or a special membrane in the case of enthalpy (moisture recovery) exchangers. The mentioned plates create air supply and exhaust channels isolated from each other. The air streams do not contact each other while flowing through the exchanger. Then the phenomenon of recuperation , i.e. heat recovery, occurs. The stream of warm air (exhausted from the rooms) heats the exchanger plates, while the stream of cold air (supplied from the outside) receives heat from the heated plates. In winter, moisture condenses on the surface of the exchanger due to the temperature difference between the supply and exhaust air.

The condensed condensate is drained to the drip tray, and its excess partially freezes, blocking the spaces through which the air flows. This process is popularly called exchanger frosting. Anti-freeze protection must be used when the outside temperature is lower than -4 °C. Air handling units with plate exchangers are equipped with security systems in the form of an empty chamber with a damper located next to the exchanger (commonly called by-pass), an electric pre-heater or algorithms regulating the operation of fans. Depending on the method of air flow, plate exchangers are divided into cross-flow or counter-flow.

Check out recuperators at the Onninen wholesaler

Cross flow exchanger

The cross-flow exchanger is constructed in such a way that the air channels of the supply and exhaust streams are perpendicular to each other. It looks as if the air streams were crossing each other (hence the name). In fact, they run in separate channels. Due to the relatively short contact time of the air streams, the efficiency of cross-flow exchangers is lower than that of counter-flow exchangers and ranges from 50 to 75%. Cross-flow exchangers are the most susceptible of all to frosting. Their advantage is undoubtedly simplicity, which translates into a favorable price.

The cross-flow exchanger is constructed in such a way that the air channels of the supply and exhaust streams are perpendicular to each other. It looks as if the air streams were crossing each other (hence the name). In fact, they run in separate channels. Due to the relatively short contact time of the air streams, the efficiency of cross-flow exchangers is lower than that of counter-flow exchangers and ranges from 50 to 75%. Cross-flow exchangers are the most susceptible of all to frosting. Their advantage is undoubtedly simplicity, which translates into a favorable price.

Counter-flow exchanger

The counter-current exchanger is more complex than the cross-flow exchanger. This is its improved version. The basic difference is that in the central part of the exchanger, the supply and exhaust ducts run parallel to each other. The streams flow in opposite directions. Thanks to this, the cold air passing through the last section of the exchanger is heated by the warmest exhaust air. Recuperators with a counter-current exchanger are characterized by higher efficiency than those with a cross-flow exchanger. Their efficiency reaches up to 90%. They are less susceptible to frosting, but the unit still has a number of protections aimed at defrosting the exchanger in winter, when water vapor condensation occurs continuously. Due to their construction, they are more expensive than cross-flow heat exchangers.

Condensing counter-flow heat exchanger

A counter-current heat exchanger that irreversibly removes condensate from the air circulation is called a condensing counter-current heat exchanger. Which can be both its advantage and disadvantage. Water vapor gains generated by household members are usually not sufficient to cover the losses caused by continuous operation of mechanical ventilation. Therefore, in winter the air becomes dry, which has a significant impact on the comfort of use. In turn, during rainy and transitional periods, the presence of such an exchanger allows the air in the building to be dried.

It is also useful at the beginning of use of a new building, when moisture is still accumulated in plasters and screeds. At this point, it would be reasonable to consider using a supply air humidifier. However, their popularity on the Polish market is low. Manufacturers who offer a humidifier often adapt it to operate only with a dedicated control panel of their production. And from a purely commercial point of view, it's hard to blame them.

Enthalpy exchanger

The difference between an enthalpy and a condensing counter-current heat exchanger is the material used to build the plates. In the case of an enthalpy counter-current heat exchanger, the plates are made of a polymer membrane, which is like a filter enabling the transfer of water vapor. Heat recovery and partial moisture recovery take place via such an exchanger.

The difference between an enthalpy and a condensing counter-current heat exchanger is the material used to build the plates. In the case of an enthalpy counter-current heat exchanger, the plates are made of a polymer membrane, which is like a filter enabling the transfer of water vapor. Heat recovery and partial moisture recovery take place via such an exchanger.

An additional advantage of enthalpy exchangers is a larger operating range, without the need to use additional anti-freeze protection (operation down to -8°C). However, AHUs with these exchangers are equipped with the security systems mentioned above. Recovering moisture in winter is advisable and solves the problem of dry air. However, it should be remembered that the mentioned recovery may also take place in summer. The indoor air humidity must then be higher than the outdoor air humidity.

Counter-flow spiral exchangers

It is worth mentioning that there are counter-current spiral heat exchangers. The design of such a heat exchanger is protected by a patent claim. This is a unique solution, implemented by one of the Polish companies. The exchanger is made of aluminum foil and spirally rolled galvanized sheet metal and shaped in the form of a cylinder. The exchanger is structurally divided into two independent spaces: supply air and exhaust air.

Both spaces are separated by a seal, ensuring precise separation, which allows heat to be recovered from the exhaust air without mixing it with the supply air. The spiral design of the exchanger causes the air to flow in a circle, countercurrently and partly crosswise. The large heat exchange surface and long air flow path make the exchanger resistant to frosting, and its efficiency exceeds 85% with the amount of supply air to exhaust air in a ratio of 1: 1.

High resistance to frost distinguishes recuperators with this solution and allows them to be used without protective heaters at the fresh air inlet and without defrosting systems required in other devices of this type. No need to use a pre-heater to protect the exchanger against frosting at low temperatures gives measurable savings throughout the year.

Rotary condensing heat exchanger

The condensing rotary heat exchanger is made of alternately arranged corrugated and flat aluminum sheets wound on a special cylinder (drum). The sheet metal creates channels through which the supply and exhaust air streams flow alternately from the rooms. A drive belt is wrapped around the exchanger, which, driven by the engine, sets the roller in motion (rotation around its own axis). During rotation, energy recovery takes place based on the regeneration process.

A characteristic of the regeneration process is the fact that the internal and external air streams contact the same surface of the exchanger (mix), thanks to which heat recovery and partial moisture recovery are possible. In winter, when the outside air temperature is low, the air exhausted from the rooms cools down to a temperature below the dew point, which leads to condensation. The water settles in the channels and then, as a result of the exchanger's rotation, it is placed in the cold surroundings of the outside air.

A characteristic of the regeneration process is the fact that the internal and external air streams contact the same surface of the exchanger (mix), thanks to which heat recovery and partial moisture recovery are possible. In winter, when the outside air temperature is low, the air exhausted from the rooms cools down to a temperature below the dew point, which leads to condensation. The water settles in the channels and then, as a result of the exchanger's rotation, it is placed in the cold surroundings of the outside air.

The outside air warms up and causes some of the condensate to evaporate and go back into circulation, thus partially humidifying the fresh air. The process continues uninterrupted and the condensate does not have enough time to freeze. This is where the advantage of rotary heat exchangers emerges: they can operate at very low external temperatures (-30°C) without the need to use anti-freeze protection. The disadvantage is the dependence on mechanical components (engine, drive belt, etc.) and additional power consumption (need to supply additional power supply).

Sorption rotary heat exchanger

A sorption rotary heat exchanger is nothing more than a condensing exchanger equipped with an additional hygroscopic material that allows it to absorb water vapor from the air. Such an exchanger is able to recover up to 90% of moisture from the exhaust air. The absorption of water vapor from the air occurs both in winter and summer and is not based on the phenomenon of condensation. The use of this type of exchanger will work well in rooms with low air humidity, and the introduction of another exchanger (condensing rotary or enthalpy counter-current) would not bring satisfactory results due to too low moisture recovery.

What should you consider when choosing a recuperator?

The choice of a recuperator should be preceded by a basic analysis of the needs of people using ventilated rooms. We will choose a device for an office space differently than for a residential house. When it comes to single-family and multi-family buildings, it is always necessary to take into account that each family is different, has different habits and way of functioning, which is closely related to the generation of moisture gains. Moisture gains should be a key consideration when selecting the appropriate energy recovery solution.