Heat pump installations are extremely popular among investors, but they have a number of technical requirements that installers should remember. Only fittings of appropriate quality ensure energy-saving operation of the system and, consequently, customer satisfaction. Which valves meet the high expectations of users?

From this article you will learn:

- what role do thermostatic mixing valves and switching valves play,

- why the quality of heating installation fittings matters,

- which valves can be regenerated and which need to be replaced completely.

Valves in the heating system - small size, big importance

Thermostatic mixing valves and diverter valves from ESBE are important components of heat pump installations. The fittings bodies are made of a special brass alloy that is resistant to dezincification. Thanks to this, under normal conditions, the valves do not require maintenance, thus meeting the main expectations for heat pump installations, i.e. efficiency, tightness, energy efficiency and low operating costs.

Thermostatic mixing valves and diverter valves from ESBE are important components of heat pump installations. The fittings bodies are made of a special brass alloy that is resistant to dezincification. Thanks to this, under normal conditions, the valves do not require maintenance, thus meeting the main expectations for heat pump installations, i.e. efficiency, tightness, energy efficiency and low operating costs.

Thermostatic safety

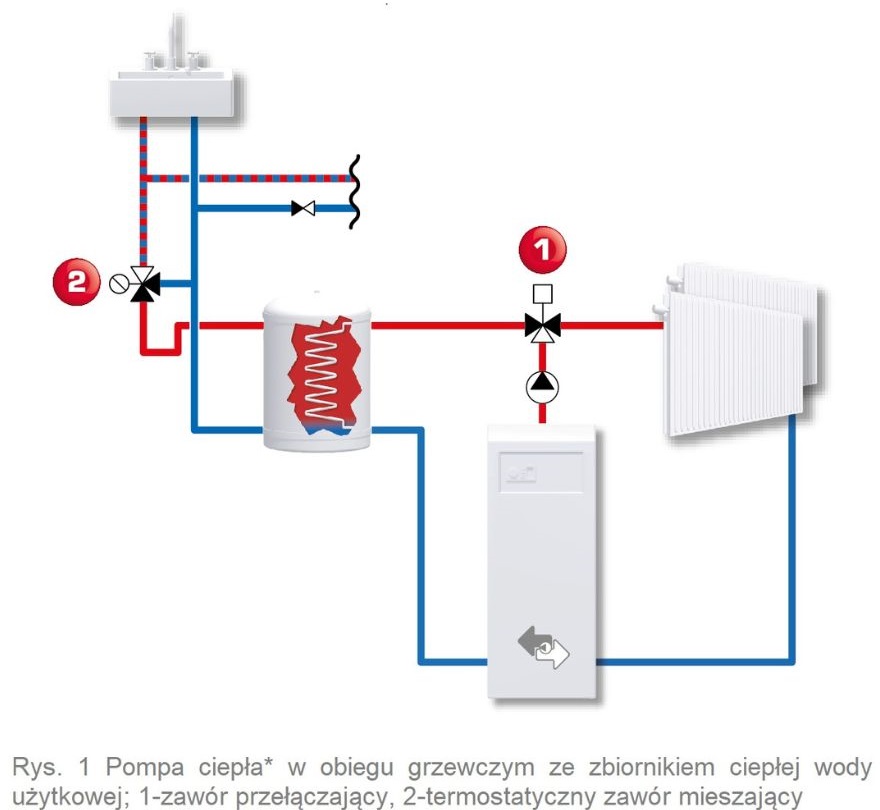

Thermostatic mixing valves are used in installations with a heat pump with a hot water tank . Heat pump installations can be both low- and high-temperature, so the thermostatic mechanism is particularly important to protect the user against water at too high a temperature. Another important feature that makes thermostatic mixing valves suitable for installations with heat pumps is their high throughput (example Kvs is 3.4 m 3 /h).

In the same installations, ESBE switching valves play an important role, characterized by a short (3-second) switching time (this applies to VZC and VZD valves). The valves are controlled by a 2-point SPST (Single-Pole Single-Throw) control signal. The signal is responsible for switching the medium flow between the valve stubs ("leading" further to the radiators or the hot water tank). Only extreme positions within the actuator's operating range are used. It is not possible to set intermediate positions.

Check out our offer of thermostatic mixing valves

Additional solutions

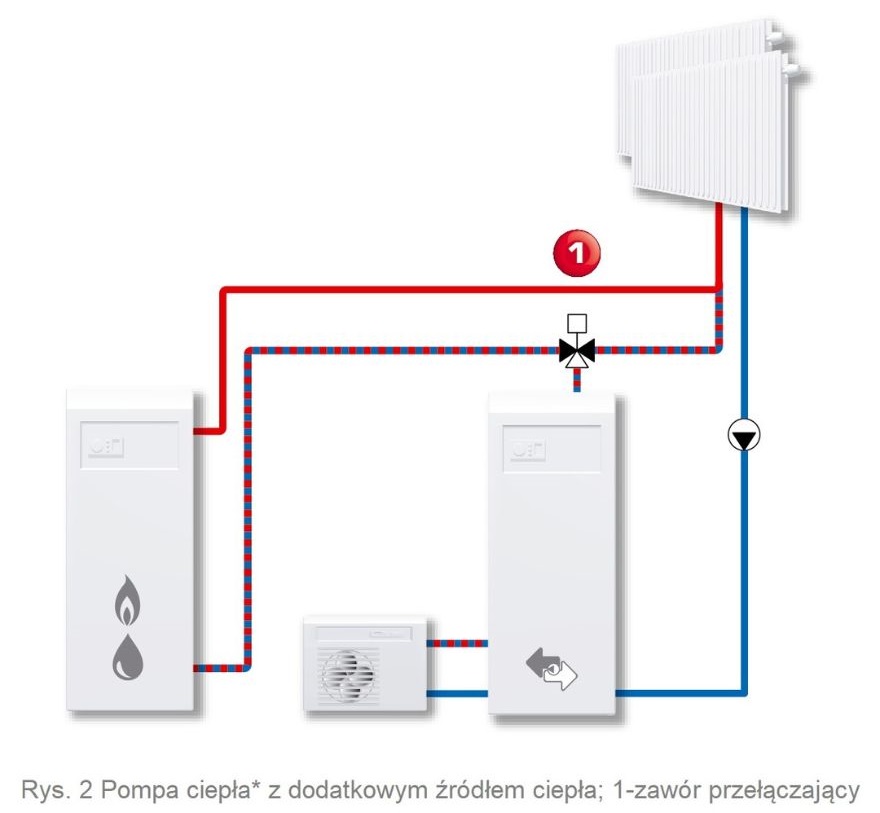

Switching valves are also used to switch between heat sources. They are common due to their high throughput and fast switching time

in installations with heat pumps and an additional heat source (e.g. gas boiler).

Within a few seconds, the valve switches to the "working" source, allowing hot water to be transported in the heating circuit. The combination of a heat pump and a second heat source is used, for example, in modernized heating systems.

Although installers prefer instant solutions in heat pump installations, ESBE MBA130 switching valves can also be found. All ESBE valves are tight and compact, which means they can be installed in spaces with a relatively small area. The valves described earlier can be regenerated using available spare parts (actuator, complete interior, cable) , while MBA130 switching valves can only be replaced as a whole, with new ones.

The proper operation of thermostatic mixing valves and switching valves affects the efficiency and performance of the entire installation. It is worth choosing a proven and reliable solution!