In which facilities is a forced-air water heater best suited? What are the criteria for selecting a forced-air water heater for a given room? At what height should the heater be mounted? Only at onninen.pl practical questions and answers.

VOLCANO heaters are an integral part of modern heating installations. Used in medium- and large-size buildings, they eliminate the problem of underheating and the negative impact of atmospheric factors on the interior. VOLCANO water heaters meet the expectations of the most demanding users. VTS heaters are devices whose design and operating parameters meet a number of requirements set by European standards and are confirmed by international Eurovent and TÜV certificates.

See the VTS brand zone in the warehouse

VTS has its own production plants for Central VENTUS in Poland, China, India and Atlanta to deliver devices quickly to various regions of the world, heaters and curtains are manufactured only in Poland. The production of devices is based on modern and very restrictive standards developed by VTS Group. All components and semi-finished products delivered to the Centers are prepared based on the company's patents and standards. Repeatable, high quality is confirmed by independent certificates.

- In which facilities is a forced-air water heater best suited?

- What are the criteria for selecting a forced-air water heater for a given room?

- What is the power range consumed by these devices?

- At what height should the heater be mounted?

- Is it possible to obtain a uniform temperature in the entire heated space by heating a room with a water forced-air heater?

- Can the stream of warm air produced by the heater be freely adjusted? (force, direction, angle, etc.)?

- Can the heaters be hung in various positions, including on the ceiling?

- Can heaters work with any heat source, including heat pumps?

- What parameters should the water supplying the device have?

- Can heaters also be used to cool rooms?

- How can we ventilate a room using a heater?

- Which elements of a device have the greatest impact on its energy efficiency?

- Can forced-air water heaters work with the BMS system? If so, how is their work optimized?

- How often should these devices be serviced and what activities should be performed to prolong the reliable operation of the heater?

Questions & Answers:

1. In which facilities is a forced-air water heater best suited?

Blower heating is best used in production halls, production and storage halls, warehouses, workshops, service centers, showrooms, sports facilities, supermarkets, commercial facilities, religious buildings and many others where we want to quickly and effectively distribute warm air in the room.

2. What are the criteria for selecting a forced-air water heater for a given room?

Each selection of equipment is made in relation to the specific needs of the facility. The selection of heater models offered by VTS EUROHEAT allows for easy adjustment to the needs of a given room.

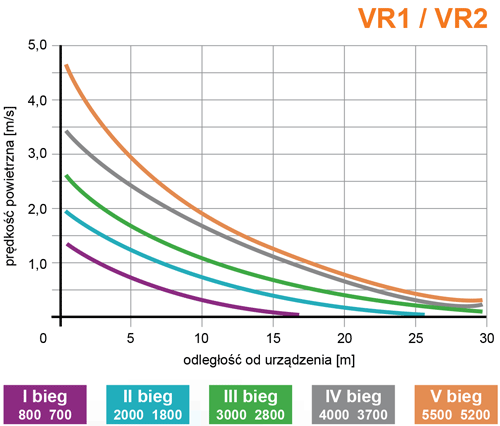

Correct selection begins with determining the heat demand. The next important step in the selection is the temperature of the heating medium that will be generated by the heat source and the target temperature that is to prevail in the facility. Having this data, we can read the heating power of individual heater models for specific fan outputs in relation to the technical parameters of the devices. Depending on the purpose of the facility, an important aspect is the speed of the air flow, i.e. the speed of the fan and the type of exchanger, which is selected depending on the temperature of the heating medium. The higher the medium temperature, the more often smaller exchangers are used, e.g. VOLCANO VR1. At medium temperatures below 70/50°C, it is recommended to use heaters with a double-row exchanger, i.e. VOLCANO VR2 or VOLCANO mini heaters.

Correct selection begins with determining the heat demand. The next important step in the selection is the temperature of the heating medium that will be generated by the heat source and the target temperature that is to prevail in the facility. Having this data, we can read the heating power of individual heater models for specific fan outputs in relation to the technical parameters of the devices. Depending on the purpose of the facility, an important aspect is the speed of the air flow, i.e. the speed of the fan and the type of exchanger, which is selected depending on the temperature of the heating medium. The higher the medium temperature, the more often smaller exchangers are used, e.g. VOLCANO VR1. At medium temperatures below 70/50°C, it is recommended to use heaters with a double-row exchanger, i.e. VOLCANO VR2 or VOLCANO mini heaters.

The last important issue is the purpose of the facility and the installation height. If it is, for example, a commercial and service room, the third fan speed is the maximum speed so that people near the device stay in comfortable conditions. The heating power of the device is read for a given temperature of the heating medium for a given fan speed and the air inlet temperature, which should be equal to the target temperature we want to achieve in the heated room.

In warehouse halls, where the speed of air flow and noise are not of great importance, the devices, both when mounted under the ceiling or on the wall, operate without regulation with maximum output or can be equipped with the new 0-10V automation available in VTS EUROHEAT, where the fan speed is selected depending on difference between target and prevailing temperatures. An interesting function of the 0-10V automation, apart from its automatic and intuitive operation, is the ability to interfere with the sensitivity of the 0-10V signal depending on the temperature difference in the modification range of +10, +20, +30 or +40%, which gives full possibility of adapting to a given type of object. This function allows you to turn on the fan at a higher capacity even with small temperature differences, a very useful aspect for facilities with an area of over 150 m², where a quick and effective response of the fan to rapidly changing conditions is often needed.

Taking into account all the above information, it is possible to select heaters in a simplified way to cover the building's thermal demand. The power of the heat source should correspond to the minimum power needed to cover the heat demand.

The simplified selection calculation itself can be described as follows: divide the power of the source by the heating power of the selected heating and ventilation device in a given gear and we will get the number of devices that should be used in our facility.

3. What is the power range consumed by the heaters?

Depending on the type of heater and the operation in individual regulator gears, the engine power varies. However, the maximum power consumed by the device is at the level of the rated power of the fan motors used. The fans of the Volcano VR1/VR2 heaters move a lot of air, above 5,000m³/h, so the power of the engine used is 530W, the Volcano mini has a smaller fan, so the maximum engine power here is 124W.

4. At what height should the heater be mounted?

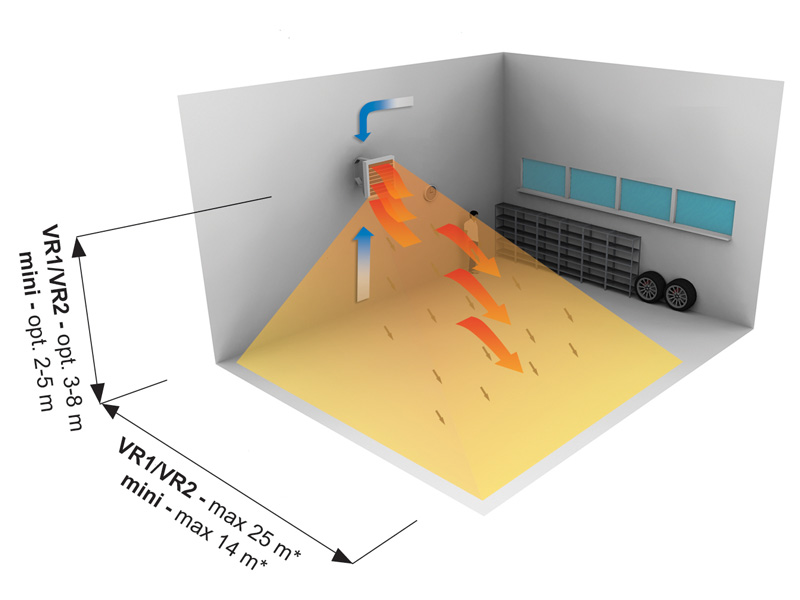

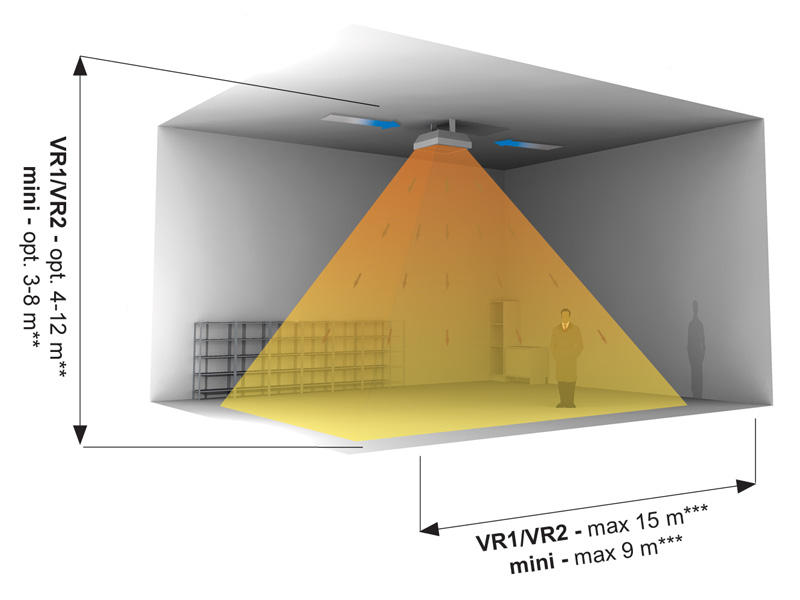

Depending on the type and purpose of the facility, the devices can be mounted on the wall or under the ceiling. Especially in high buildings, i.e. from 7 m, it is suggested to install the heaters both on the wall and under the ceiling. Heaters mounted under the ceiling also serve as destratifiers, so there is no need to equip the facility with these additional devices. To effectively distribute heat, heaters are most often mounted on the wall at a height of 3 to 6 m and under the ceiling at a height of 7 to 12 m.

| On the wall: | On a ceiling: |

|  |

|---|---|

| VR1/VR2 - optimal height: from 3 to 8 meters Mini - optimal height: from 2 to 5 meters | VR1/VR2 - optimal height: from 4 to 12 meters Mini - optimal height: from 3 to 8 meters |

5. When heating a room with a water forced-air heater, can a uniform temperature be achieved in the entire heated space?

The advantage of forced air heating is obtaining an even temperature in the heated room. Forced convection of heat caused by the fan's operation causes quick and effective heat delivery. Uniform heat distribution is achieved with the correct selection of devices, good correlation with the heat source and appropriate automation. All aspects especially described in point 2 from the selection of the number of devices, the selection of appropriate automation elements affects the heat distribution. When selecting, you should take into account the arrangement of devices, which also determines the method of heat distribution. The devices should be installed alternately to ensure the best possible heat distribution.

6. Can the stream of warm air produced by the heater be freely adjusted? (force, direction, angle, etc.)?

There are many different installation configurations for VOLCANO heaters. The devices are designed to be as adaptable as possible to the requirements of a given project, ensuring the most effective distribution of heated air in the heated room.

The airflow direction can be achieved in two planes, horizontally it is possible to rotate the device on the console by +/-60° angles (right and left). In the vertical plane, you can use the console shift by +/-20° (up and down). In the vertical plane, it is also possible to individually adjust the air blades; in VOLCANO VR1 and VR2 heaters, each blade can be set independently in four positions. In the case of installing heaters in a ceiling system, you can also remove half of the air guides in VOLCANO VR1 and VR2 and reverse them to obtain a better air distribution to the right and left.

Volcano MINI heaters have similar installation solutions as VOLCANO VR1 and VR2. The blades allow for stepless adjustment, which allows for better adjustment of the airflow direction to the requirements of the project.

There are also solutions where mounting on a console dedicated to the device is not used. Here, too, the heaters have additional holes in the exchanger frame, thanks to which the heaters can be installed on another supporting structure for effective air distribution.

The air blowing force is regulated using automation.

7. Can the heaters be hung in various positions, including on the ceiling?

In the previous points, the possibilities of air distribution in a heated facility with various heater installations were partially highlighted. In many cases, it is suggested to install it on the ceiling, especially in high halls. Due to the accumulation of air under the ceiling, it is advisable to install heaters under the ceiling in order to push the accumulated air while heating and distributing it well. There are also very good solutions for wall and ceiling installation to heat the facility even more effectively. In such a configuration, even for small objects, only two heaters are installed, where one is mounted on the wall and the second one is mounted 2/3 of the distance from the first one under the ceiling, assuming that the object is at least 7 m high.

8. Can the heaters work with any heat source, including heat pumps?

Heaters can operate with various heat sources with different parameters. However, it should be remembered that when the temperature of the supply medium is lowered, the heating power of the heaters decreases. Heat pumps for space heating are gaining popularity. In such a system, we also need the largest possible heat exchanger. In a configuration with heat pumps, the VOLCANO VR2 heater works best from the VTS EUROHEAT range. If a given facility has a certain heat demand, a given heating power value should be provided regardless of the type of heat source. If the temperature of the medium is low, the device produces lower heating power, so in order to provide the appropriate amount of energy to the room, it is necessary to use a much larger number of devices.

9. What parameters should the water supplying the heaters have?

Feeding water parameters depend on the availability of media, e.g. from the municipal heating system or your own heat source. The Volcano VR1 and VR2 heaters are designed to operate with a refrigerant up to a temperature of 130°C, and the VOLCANO mini heaters with a refrigerant temperature of 120°C. The most common supply temperature for heaters is 70/50°C and 80/60°C, which determines cooperation with gas and solid-fuel boilers using biomass or eco-pea coal.

10. Can heaters also be used to cool rooms?

Naturally, VOLCANO VR1 and VR2 heaters can also be used to cool rooms. Here, similarly to heating with a low-temperature medium, the VOLCANO VR2 heater works better. Please note that the heaters from the regular VTS EUROHEAT brand offer do not have a drip tray for draining condensate. Any modification is the responsibility of the user, VTS has instructions on how to drain condensate for VR1 and VR2 heaters. An important aspect is the entrainment of condensate - Volcano heaters are not equipped with a mist eliminator, so to prevent condensate from being carried away from the fins of the device's exchanger, it is suggested to use the devices at maximum the third fan speed.

11. How can we ventilate a room using a heater?

Even if we do not have access to chilled water in the facility, we can use the fan itself to cause air movement. Mechanical ventilation alone, which involves exchanging air with heaters alone, is not possible. However, as a result of fan operation, heaters effectively support the ventilation system by distributing air from ventilation units. The new 0-10V automation, which includes the HMI VR controller, allows you to enter the cooling mode with one switch and ventilate the facility in the summer.

12. Which elements of the device have the greatest impact on its energy efficiency?

The energy efficiency of the product depends on all the components that make up the device and on the accuracy of their fit. It might seem that a heater is a simple product because it contains only three main components: exchanger, fan and casing. The executive element of the air flow is the fan, the exchanger releases heat and the whole thing is closed by a casing. However, a heat exchanger must be well matched to a given fan capacity for the entire system to operate as efficiently as possible. These elements constitute the executive heating system, but this is not the end of the designers' work. For these components to work well, they must be placed in a housing that will ensure a perfect fit without, for example, blow-bys outside the heating light of the heat exchanger.

The air distribution should also be as good as possible and take place at the same speed across the exchanger. A perfect example is the VOLCANO mini heater, where thanks to the casing made of foamed polypropylene, such a solution was perfectly implemented while maintaining the small depth of the entire device.

The air distribution should also be as good as possible and take place at the same speed across the exchanger. A perfect example is the VOLCANO mini heater, where thanks to the casing made of foamed polypropylene, such a solution was perfectly implemented while maintaining the small depth of the entire device.

The casing structure should ensure tightness not only on the fan side, but also on the front and side parts of the exchanger. There are many solutions on the market where the fan funnel is screwed to the exchanger and an aesthetic front panel is placed on the front. Unfortunately, it does not connect to the fan funnel, so the exchanger is not closed in a tight housing. This causes heat loss from the exchanger and reduces the effectiveness of the entire device in releasing heat to the air pumped by the fan.

All components are tightly closed in the housings of VOLCANO heaters and the housing materials used do not have high thermal conductivity coefficients, therefore the VOLCANO housings do not heat up as in the case of heaters in a sheet metal housing or in those where the efficiency is disturbed by a gap between the front panel and the fan funnel. The casing of VOLCANO mini heaters is an excellent material in terms of not only acoustic but also thermal insulation. This casing tightly closes the device's components on all sides, so that the casing does not heat up at all during operation, and all the heat from the exchanger is directed to the pumped air. It can be safely said that currently there is no such device on the European market that effectively and tightly protects the heat exchanger from the side of the housing heating up during operation. The efficiency of heat transfer to the flowing air is the best in this case.

Therefore, all components are very important and only their precise fit will affect the final efficiency of the device. Even the use of a perfect fan with design errors will nullify any savings achieved in this way.

13. Can forced-air water heaters work with the BMS system? If so, how is their work optimized?

Currently, the BMS system, i.e. the master building management system, is more and more often found in new or large buildings. VTS EUROHEAT has introduced an HMI VR controller to its offer, which as standard has the ability to connect and configure using the MODBUS RTU protocol via an RS485 connector. The controller manages a maximum of eight ARWE3.0 regulators, i.e. it can support up to eight VOLCANO VR1/VR2 devices or 24 VOLCANO mini devices (one ARWE3.0 regulator works with three VOLCANO mini heaters). You can remotely read parameters and save new ones from the HMI VR controller.

14. How often should heaters be serviced and what activities should be performed to prolong the reliable operation of the heater?

Servicing heaters is not difficult, but it depends on how they are installed in the facility. However, focusing on the aspect of cleaning itself and its cyclical nature, it largely depends on the conditions in which the device is used. It is recommended to clean the exchanger on the air flow side once a year using compressed air before the heating season. If necessary, the housing and fan box should also be periodically cleaned to remove dust and grease deposits. Once every three years, it may be suggested to rinse the exchanger with warm water in the opposite direction to the flowing heating medium, and if the device is not dismantled, to release the water through the exchanger drain. During the first inspection of the devices, it is also suggested to check and, if necessary, tighten all cables in the engine box and in the automation elements. It is recommended to check the connection of electrical cables once after the first season of using the devices.

He replied:

Wojciech Lew Kiedrowski

Product Manager VTS EUROHEAT