In order for underfloor heating to work flawlessly, providing pleasant warmth in the interior, it must be equipped with a manifold. This is a key element influencing the efficiency and durability of the entire installation. We distinguish brass and stainless steel manifolds. Each of them has different properties, which is why in the following article we will look at these models, assessing how a brass manifold affects the operation of the heating system and how the installation with a steel manifold works. At the very end, we will compare both solutions, which will help you make an informed decision about choosing the right manifold for the underfloor heating system.

Check out the underfloor heating manifolds at the Onninen wholesaler

Operation of the heating system with a brass distributor

The popularity of underfloor heating, commonly known as floor heating, is very high. This is not surprising, considering how it works, especially in comparison to traditional radiator heating. The heat is distributed differently, more evenly, which creates a pleasant microclimate. It fits perfectly into any room, including bathrooms.

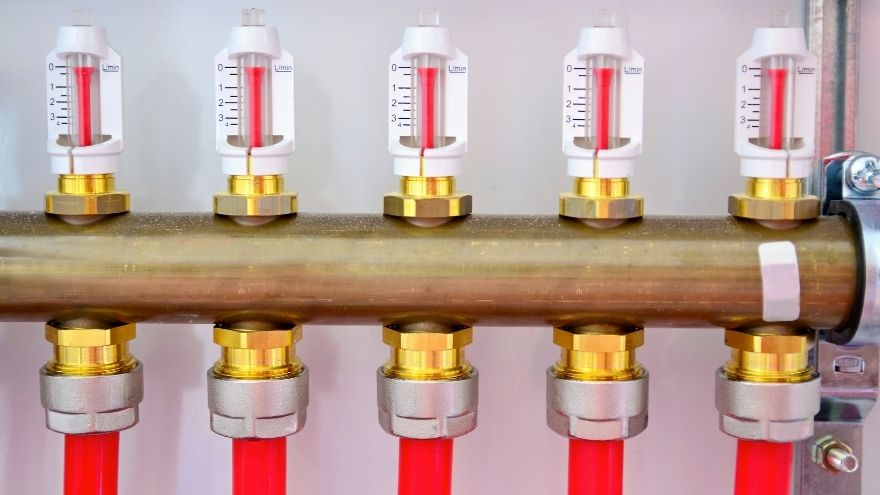

As we have already mentioned, the underfloor heating manifold is of key importance here, which is quite often made of brass. This is due to its properties - heat conduction, as well as corrosion resistance. Brass manifolds effectively support the even distribution of heat throughout the system, being able to contribute to the optimal operation of the heating system. Such a manifold for underfloor heating is also quite easy to install, at the same time showing a high level of durability. Such pipes are resistant to various factors, which translates into their long service life.

As we have already mentioned, the underfloor heating manifold is of key importance here, which is quite often made of brass. This is due to its properties - heat conduction, as well as corrosion resistance. Brass manifolds effectively support the even distribution of heat throughout the system, being able to contribute to the optimal operation of the heating system. Such a manifold for underfloor heating is also quite easy to install, at the same time showing a high level of durability. Such pipes are resistant to various factors, which translates into their long service life.

However, it is worth knowing that in places where the water is very hard, there is a risk of scale deposits in the manifold, which unfortunately over time can reduce its efficiency and that of the entire installation. Despite this drawback, many people decide to buy such manifolds, because they are a good compromise between price and quality.

Functioning of the heating circuit with a steel distributor

The underfloor heating distributor is therefore an extremely important element. It is often made of brass, but also of stainless steel. This solution is particularly valued for its exceptional durability and corrosion resistance, especially since underfloor heating systems are in constant contact with water. Steel components are highly valued here, as are other elements made of stainless steel, such as shut-off valves, drain valves, flow meters, air vents, etc.

The underfloor heating distributor is therefore an extremely important element. It is often made of brass, but also of stainless steel. This solution is particularly valued for its exceptional durability and corrosion resistance, especially since underfloor heating systems are in constant contact with water. Steel components are highly valued here, as are other elements made of stainless steel, such as shut-off valves, drain valves, flow meters, air vents, etc.

Stainless steel is also exceptionally resistant to aggressive factors, such as salts, which may be present in water. Underfloor heating loops designed in this way also perform better in systems where temperature and pressure may change. At the same time, remember that steel models are more resistant to mechanical damage, especially when compared to brass manifolds. On the other hand, stainless steel cannot conduct heat as well as brass.

What would be a better solution? Brass or steel manifold?

Considering everything we have written about the operation and use of manifolds - brass and stainless steel - the question arises: what will be the better solution? What to choose? In fact, a lot depends on various factors, such as durability, cost and specifics of the installation.

Considering everything we have written about the operation and use of manifolds - brass and stainless steel - the question arises: what will be the better solution? What to choose? In fact, a lot depends on various factors, such as durability, cost and specifics of the installation.

Let us recall that brass distributors are characterized by excellent thermal conductivity, thanks to which heat distribution is extremely effective. Another advantage is the ease of installation. Corrosion resistance is also good, which means that this mechanism can operate for a long time without losing quality. Unfortunately, it does not look so good in the case of hard water - here, brass distributors can be exposed to scale formation, which consequently limits their efficiency.

This problem does not exist if we choose stainless steel manifolds, especially proven ones like the KAN-therm manifold , because they provide greater corrosion resistance. Thanks to this, they are more suitable for difficult operating conditions. As if that were not enough, they also demonstrate very high durability against mechanical damage, so they operate reliably in long-term installations.

Check out the underfloor heating manifolds at the Onninen wholesaler