Optical fiber is the technology of the future. In Poland, the largest fiber optic network belongs to Orange, and its length is over 100,000 kilometers. For several years, the demand for fiber optic services has been constantly increasing, so it is worth familiarizing yourself with what it is like to work with fiber optics, what its types are and what its structure looks like. The practical use of optical fibers during installation work requires greater technical knowledge and precision than when working with standard twisted pairs.

Are you starting to work with fiber optics? This article is for you!

After reading you will know:

- what are the types and construction of fiber optic cables

- what are the methods of marking optical fibers and what are their marking systems

What are you looking for?

See fiber optic cables in Onninen

Types of optical fibers

The optical fiber transmission medium is based on a mode structure where the transmission medium is light. Optical fibers can also be categorized based on fiber geometry and refractive index distribution. There are single-mode and multi-mode optical fibers on the market, which differ, among others, in: the thickness of the glass core responsible for information transfer parameters.

Single-mode optical fiber

Single-mode optical fibers consist of a core with a diameter of approximately 9 +/- 2 µm, which is characterized by a step change in the refractive index. The optical fiber cladding is standardized and its diameter is 125 µm. Single-mode fibers have low inter-mode dispersion, which causes little interference. The light wave runs almost parallel to the axis of the optical fiber, reaching the end of the fiber in the fundamental mode.

Thanks to the possibility of using many protocols at the same time, low attenuation, and small core diameter in which only one mode of light is transmitted, single-mode fibers are perfect for transferring information over long distances - up to 120 km without the need to use a repeater to regenerate the signal. Single-mode fibers enable signal transmission in xWDM technology (flow at Tb/s level). There are four basic types of optical fibers in single-mode optical fibers.

Types of fibers

| Fiber type | Description |

|---|---|

| G.552D (SM2) | Fibers with unshifted dispersion. One of the most popular fibers with a standard bending radius of 30 mm. Adapted to the transmission of light waves with a length of 1310 – 1550 nm. |

| G.657A1 (S7A1) | Fibers with a twice-reduced bending radius. These are fibers with a bending radius twice reduced compared to standard SM fibers (15 mm). They are compatible with them. |

| G.657A2 (S7A2) | Fibers with a 3-fold reduced bending radius. These are fibers with a bending radius of 10 mm. They are compatible with SM2 single-mode fibers. |

| G.657B3 (S7B3) | Fibers with a 4-fold reduced bending radius to 7.5 mm. Due to their much smaller diameter, the mode fields are not compatible with single-mode SM2 fibers. |

Multimode optical fiber

Multimode fibers are equipped with a much larger core, the diameter of which is 50 µm (old OM1 designs had diameters of up to 62.5 µm). Their cladding diameter is standardized and is most often - similarly to single-mode fibers - 125 µm. The transmission of a signal of the same wavelength in multimode fibers involves its scattering between many modes, the speed of which relative to the waveguide may be different, leading to a limitation of the speed or transmission distance.

This is caused by distortion of the wave impulse. Multimode fiber optics allow for effective signal transmission up to a distance of approximately 2 km (depending on the quality and class of optical equipment. Above this distance, it is necessary to use signal repeaters. Multimode fiber optics currently consist of three basic types of fibers.

Types of fibers

| Fiber type | Description |

|---|---|

| OM4 50/125 Flex | OM4 fibers are used with SFP modules and compatible with VCSEL lasers with a wavelength of 850 nm. |

| OM3 50/125 Flex | OM3 fibers are dispersible and transmit wavelengths of 850 and 1300 nm. They are intended for short transmissions (e.g. within one building). |

| OM2 50/125 | OM2 fibers, similarly to the old OM1 fiber design, transmit waves of 850 and 1300 nm and are intended for short-distance transmission. |

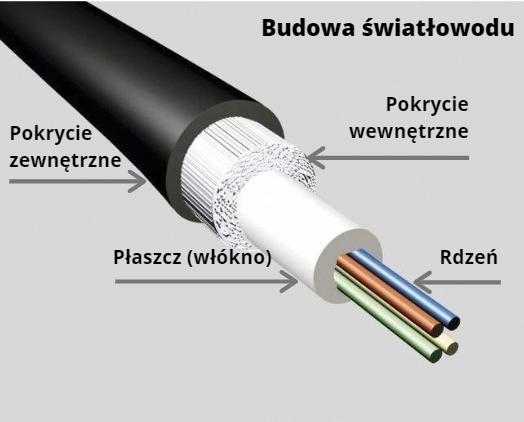

Construction of optical fiber

Optical fibers consist of three basic elements: core, cladding and covering.

Fiber optic core

The fiber optic core is the key working element that enables the transmission of the light wave. The core in fiber optic cables is made of crystalline materials, quartz, glass or polymers.

Fiber optic jacket

The optical fiber cladding is the most important protection for the core and acts as a barrier to the transmitted light wave, providing a threshold for light refraction.

Fiber optic coverage

The fiber optic covering is the outermost layer of the cable. This element is used to protect the interior of the optical fiber against mechanical damage and microcracks that could occur during installation or transport of cables. The optical fiber covering is usually made of polyethylene, PVC or polyamide resistant to moisture, extreme temperatures and UV. It is made of a multi-layer structure, which cushions the cable and allows it to absorb kinetic energy more effectively.

See fiber optic cables in Onninen

Marking of fiber optic cables on the outer sheath

Due to the great diversity of types, construction and origin of fiber optic cable manufacturers, it is necessary to use appropriate nomenclature to determine the type and parameters of the cable. The biggest problem complicating the marking of fiber optic cables is the use of three different marking systems for fiber optic cables.

In Poland, as well as in Europe, the most commonly used system for marking fiber optic cables is the European system, although the Polish system is still used in Poland.

The markings of fiber optic cables are applied to the external sheathing, and their correct recognition and decoding is crucial for the quality of the prepared technical documentation, the efficiency of the design process and the safety and efficiency of installation works.

Fiber optic cable markings provide information regarding: type of cable construction, type of seal, type of external sheathing materials, type and number of fibers inside the cable, as well as cable strength parameters. The markings are placed at 1 meter intervals. In addition, on the outer sheathing of the fiber optic cable we will find the manufacturer's name, the length from the beginning of the section (in meters), as well as additional symbols related to the purpose of the cable.

A significant problem in marking fiber optic cables is the difference between the manufacturer's marking and the marking adopted by a given nomenclature system, which can often be misleading - confuse the designer, contractor or investor. How to deal with this? You should always pay attention to the coding order, remembering that in the case of some cables, some symbols related to the structure of the cable may be missing from the marking.

Similarly, this problem can be solved for other types of cables and wires. Check out our article.

Markings of fiber optic cables

Due to current standards, guidelines and requirements, below we describe the marking of fiber optic cables in accordance with European marking.

| Position in the cable code | Designation (EU) | Description |

|---|---|---|

| Cable purpose | ||

| 1 | ||

| AND | external | |

| AND | internal, external | |

| U, I/A | internal-external | |

| S | self-supporting figure eight | |

| ADDS | self-supporting axial | |

| Material of the 1st and 2nd outer shell | ||

| 2 and 3 | - | polyethylene |

| Y | PVC | |

| Q | polyurethane | |

| V | polyamide | |

| N | halogen-free, non-flammable | |

| Xz | polyethylene with moisture protection | |

| Xn | polyethylene non-flammable | |

| Yn | PVC non-flammable | |

| Cable symbol | ||

| 4 | OTK | optocommunication |

| OTKG | mining optocommunication | |

| Type of facility | ||

| 5 | ||

| r | rose | |

| d | gelled tube | |

| S | with a semi-close or tight tube | |

| tm | with microtube | |

| ts | tube with dry seal | |

| Rs | rosette with dry seal | |

| etc | with central tube | |

| Conductivity | ||

| 6 | ||

| d | dielectric | |

| Reinforcement | ||

| 7 | ||

| D | reinforced circuit | |

| Armor | ||

| 8 | ||

| Fo | steel wire | |

| Ft | carbonated corrugated steel tape | |

| Ftl | painted steel tape | |

| Flat cable | ||

| 9 | ||

| Mr | flat cable | |

| Type of fibers | ||

| 11 | ||

| J, Jm | Single-mode fiber with unshifted dispersion | |

| Jp | SM fiber with shifted dispersion | |

| Jn | SM fiber with non-zero dispersion | |

| G | Multimode gradient fiber | |

| Permissible tension force | ||

| 12 | ||

| (number) kN | e.g. 5kN tension | |

For example - according to the European nomenclature, the A-YOTGKtm 8J optical cable means that we are dealing with an outdoor cable (A-), with a PVC sheath (Y), optical mining cable (OTG) with a microtube (tm) with 8 single-mode fibers with an unshifted dispersion.