The hydraulic clutch is a device used in heating installations. This is a way to connect different circuits, e.g. boiler and heating, which are characterized by different operating parameters. What is the function of a clutch and how to choose the right size?

Hydraulic clutch in the heating system

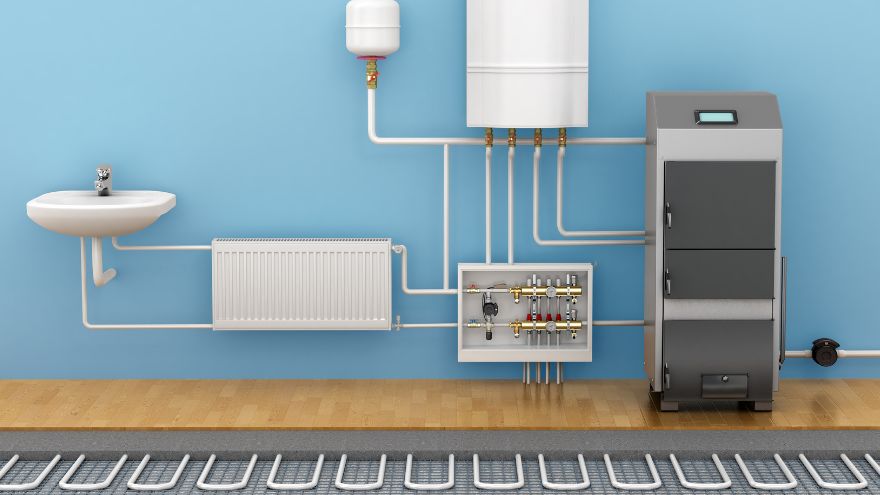

The use of a hydraulic clutch is used in medium and high power systems. The device is necessary when various systems operate at the same time, and each of them has its own heat pump. In such a structure, a device is necessary to help connect individual circuits and balance the pressure and flows between the boiler and the receiving installation. The solution is used in heating installations with heat pumps, primarily water/air type, and in compact and wall-mounted boilers where the water capacity is not large.

The use of a hydraulic clutch is used in medium and high power systems. The device is necessary when various systems operate at the same time, and each of them has its own heat pump. In such a structure, a device is necessary to help connect individual circuits and balance the pressure and flows between the boiler and the receiving installation. The solution is used in heating installations with heat pumps, primarily water/air type, and in compact and wall-mounted boilers where the water capacity is not large.

Check hydraulic clutches at the Onninen wholesaler

The construction of a hydraulic coupling is not complicated because it is a closed part of the installation with connected stubs. This is an element connecting the boiler with the installation, which is usually made of stainless or carbon steel.

The construction of a hydraulic coupling is not complicated because it is a closed part of the installation with connected stubs. This is an element connecting the boiler with the installation, which is usually made of stainless or carbon steel.

Using a hydraulic clutch brings many benefits, including extending life of the boiler and individual pumps. This is a great way to avoid having to adjust individual systems. In practice, there are various variants of the hydraulic coupling, adapted to the heating water flow rate. Adjusting the intensity allows you to mitigate the impact of the operation of individual heat receivers on its source.

In the heating system, a hydraulic clutch is used:

- when the flow resistance in the heating system is too high in relation to the lifting height specified for the circulation pump built into the wall-mounted boiler,

- when the water flow rate within the heating installation is too high and is disproportionate to the flow rate specified for a given boiler,

- in cascade boiler rooms with hanging boilers equipped with a circulation pump,

- in cascade boiler rooms where fixed and low-temperature boilers are installed, where it is necessary to ensure a specific return temperature in the circulation,

- when it is necessary to ensure cooperation between heating boilers and old elements of the heating system.

In a heating system, it is very important that individual elements are matched to specific parameters, then the efficiency of the entire system will be optimal.

Balance of heating water flow rates through the boiler and heating installation

The water flow rate in the heating system is determined together with the permissible rate for a specific boiler model. This value is given in liters per hour. The flow rate of heating water through the boiler is determined by two parameters. The first is the heating power of a specific circuit, the second is the temperature difference reached at the supply and return points. Everything is calculated based on a mathematical formula, so the results obtained are precise values that allow you to match the clutch variant to the needs and capabilities of a given system.

Check hydraulic clutches at the Onninen wholesaler

Selection of a hydraulic clutch

Hydraulic clutches are available in various variants, but the selection of the appropriate model depends on the needs of the project. When browsing the offer of hydraulic clutches, you can notice that they differ in parameters and purposes. Many manufacturers indicate what conditions and systems particular solutions are dedicated to. Information regarding the heating power that is transferred directly to the heating installation, taking into account the temperature difference achieved at the supply point and in the return to the boiler, is of great importance.

Hydraulic clutches are available in various variants, but the selection of the appropriate model depends on the needs of the project. When browsing the offer of hydraulic clutches, you can notice that they differ in parameters and purposes. Many manufacturers indicate what conditions and systems particular solutions are dedicated to. Information regarding the heating power that is transferred directly to the heating installation, taking into account the temperature difference achieved at the supply point and in the return to the boiler, is of great importance.

When looking for a suitable hydraulic coupling variant, it is necessary to determine the heating water flow rate. Proper selection of parameters allows you to obtain optimal heating parameters in the building and reduce the consumption of individual system elements. This solution is comfortable, functional and extremely practical.

The issue of the boiler you have is also an important aspect, as different solutions are used in the case of low-temperature, constant-temperature and condensing boilers. In the case of constant and low-temperature boilers, it is possible to increase the return temperature, which is not the case when condensing boilers are used.

Another criterion is the water capacity of the boiler. If the maximum heating water flow rate is lower than the installation flow rate, a hydraulic coupling must be used.