The purpose of a lightning protection system is to protect a structure from lightning strikes and safely conduct its energy to the ground via the shortest route possible. However, for such an installation to fulfill its task, it must be properly executed.

Lightnings resulting from electrical discharge have an intensity of up to 20,000 amps, which means they can heat the air to 30,000 degrees Celsius. The lightning bolts that appear seek the shortest path to the ground to equalize the potential differences between the clouds and the ground. Unfortunately, it often happens that such lightning strikes a building. This can cause various dangerous effects. When lightning strikes non-flammable material (e.g. concrete, brick), it can cause it to crack, while striking electrical wires can damage them, as well as damage devices connected to the power grid, which can even result in a fire.

The building law stipulates that a lightning protection system should be installed in buildings higher than 15 m and with an area of at least 500 m3 or in buildings made of flammable materials, as well as in every public utility building. However, it is really worth securing every residential building with a lightning rod. Additionally, when insuring a building, it is often required by the insurer to equip it with a lightning protection system and gives the possibility of applying for additional discounts related to the insurance policy.

See the lightning protection system components at the Onninen wholesaler

What does a lightning protection installation consist of?

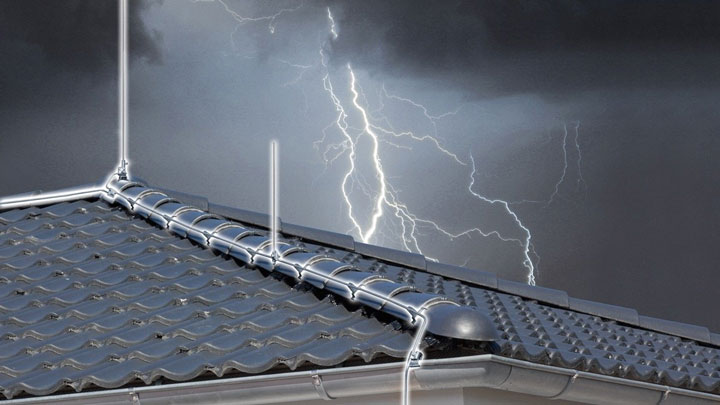

A lightning protection system is nothing more than a network of metal wires that are installed on the roof. These wires are connected directly to the ground. Thanks to this, the energy transferred by lightning is safely conducted to the ground. A typical lightning protection system, in accordance with the harmonized standard PN-EN 62305-1:2011, consists of the following elements:

Vertical and horizontal air terminals

This is part of the lightning protection system that is installed on the roof. These installation elements are most often made of galvanized steel wire , stainless steel, copper and ALMgSI aluminum alloy. Its diameter has been unified to 8 mm. Horizontal air terminals are installed along the ridge, as well as on the edge of the roof, thus creating a grid of air terminals. However, when the roof is very steep and sloping, the air terminals are mounted to it using roof brackets . Vertical air terminals protruding above the protected elements should also be used, such as: chimney spires, lightning protection masts or other types of spires isolating the lightning protection system from the protected elements extending above the roof surface, such as an antenna mast, ventilation chimney, smoke stack. It is worth knowing that the role of air terminals is often taken over by some metal parts of the house, which must be connected to the building's grounding system, or separate grounding must be provided. Most often, these are gutters, handrails, but also metal parts of the roof. However, they cannot be made of sheet metal less than 0.5 mm thick, there cannot be any flammable materials underneath them, and the connection between these elements must be electrically effective;

Drain pipes

These are elements that connect air terminals and earthing rods. They are made of the same materials used for air terminals. Down conductors can also be made of steel tape . Such elements can be installed both on the building facade (2 cm from the wall), along the gutter, and under the facade in special lightning protection pipes with resistance to electrical breakdowns (pipe strength 100 kV). It is important to remember to connect the down conductor to the earth using a test clamp. It is worth additionally securing the latter by placing it in a test box (control and measurement). For safety reasons, protective conductors should not be installed closer than 2 m from the entrance to the building. They should be installed in special test boxes (ground or facade).

Earthing

This is the last element of the lightning protection system, but no less important than the others. Earthing can be done in several ways. The first option uses the reinforcement of the building's foundation. Which must be permanently connected to the steel tape leading outside the foundation outline. This is the so-called natural earthing. Artificial earthing can also be done. The first method is to install a closed ring earthing around the building. A galvanized steel tape is used for this purpose, which is buried at a depth of 80 cm. However, a distance of 1 m from the building must be maintained. The third option is vertical earthing in the form of steel rods driven into the ground.

Principle of operation of a lightning protection installation

The purpose of installing a lightning protection system was already mentioned at the beginning of this article. It is primarily about protecting the building and being able to bring the energy transferred from lightning to the ground as quickly as possible. The principle of operation of a lightning protection system is very simple. The highest element of the system is the air terminals and it is they that take the currents when lightning strikes. You could even say that they lure the lightning to strike the air terminals and not other elements of the building. The current passes from the air terminals to the down conductors and through them reaches the grounding electrodes. It is they that dissipate the energy from the lightning. In this way, the potential difference between the clouds and the ground is equalized.

Although a lightning protection system is not mandatory for every house below 500m3, it is worth installing it to better protect the building, residents and devices connected to the power grid. However, it must be done correctly, in accordance with applicable standards, then such an installation will fulfill its task.

See the lightning protection system components at the Onninen wholesaler